China is a name that everyone remembers when it comes to manufacturing. No matter what the product, China offers manufacturing options for almost all products ranging from Diapers to Car auto parts to pharmaceuticals to luxury products. China is just as prominent when it comes to Fashion. Fashion manufacturing in China is backed by years of experience, expertise, punctuality, discipline, and infrastructure.

China is a global power when it comes to Fashion manufacturing, sourcing, and exports. It is one of the largest exporters of a wide array of products and categories. Another thing that stands out is the fact that all the years of experience are supported and assisted by the enthusiasm to innovate and be world leaders. The Chinese fashion Manufacturers have all the latest technologies, techniques, materials, methods, and processes which makes them an excellent destination for technical fabric and material innovations.

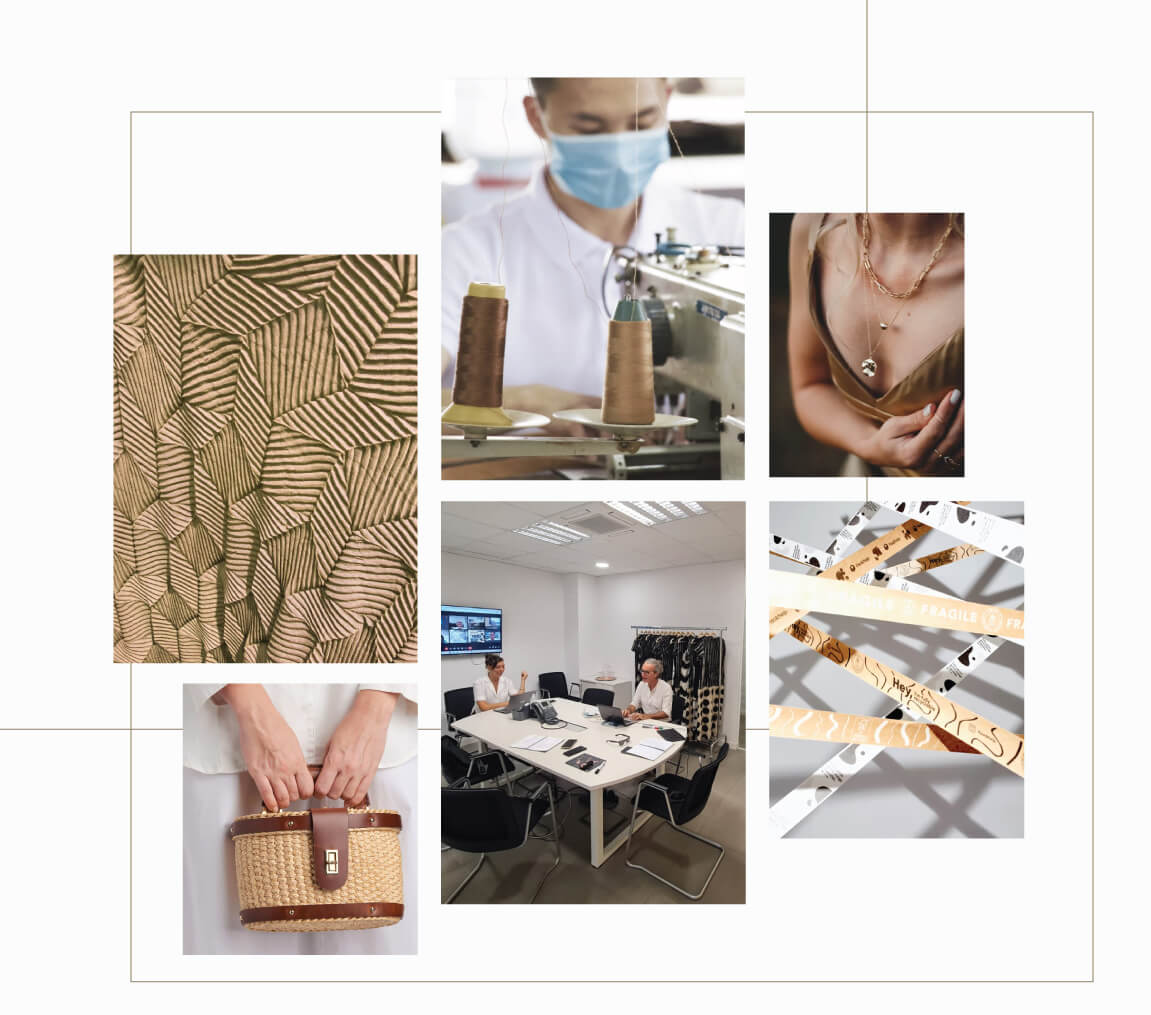

WHAT TO MANUFACTURE IN CHINA?

CASHMERE PRODUCTS:

China has one of the biggest Cashmere manufacturing and export sectors. Due to the proximity of Mongolia and Chinese influence and reach in Inner Mongolia, Cashmere has been something that the Chinese were able to tap into, especially in the 60s and 70s when the Chinese Cashmere gained a massive boom. Today, globally no other country even comes close to the magnanimity of the Chinese Cashmere. It is only distantly followed by India, Nepal, and Australia. There are so many Chinese cashmere production and Manufacturing factories and suppliers all over China. To check out Chinese Cashmere suppliers, click here.

PU LEATHER PRODUCTS:

China is one of the frontrunners when it comes to PU leather products. PU leather or Polyurethane Leather is one of the most widely used alternatives to real leather. China offers almost every single variation to PU leather materials and manufactures PU leather products across all categories like bags, wallets, shoes, accessories, hats, garments, and even lifestyle products. To find a suitable Chinese PU leather manufacturer for your project, click here.

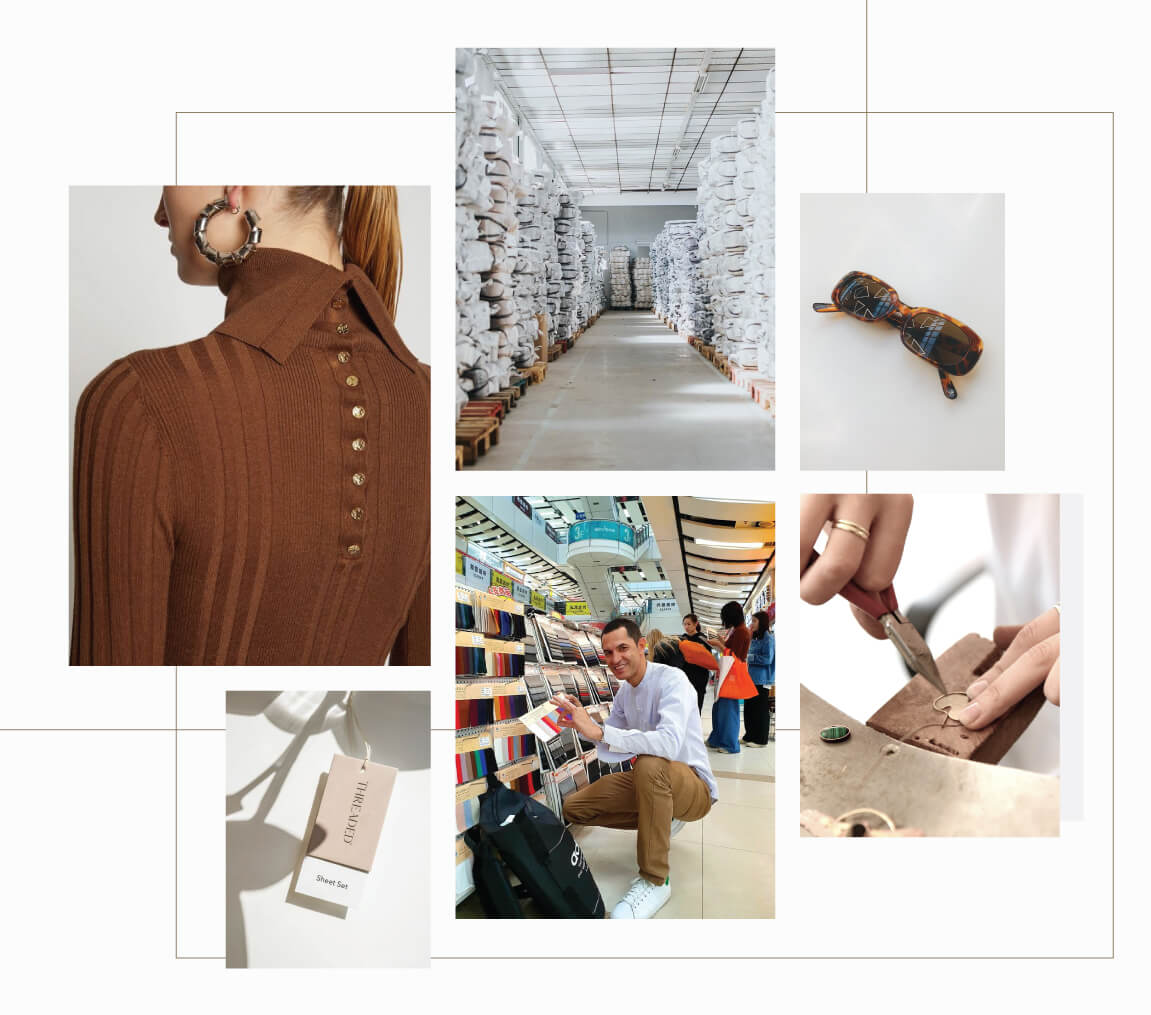

SUNGLASSES:

We have been dealing with and managing Eyewear production in China for more than 20 years now. There are a few main regions that focus on Eyewear production: Wenzhou, Guangzhou, and Dong guan. While there is a multitude of factories when it comes to Eyewear production in China Identifying and filtering down good and reliable suppliers is extremely important, since there is an abundance of Very cheap quality low-end products too. Different styles like Fashion sunglasses, Prescription eyewear, Foldable glasses, Sustainable sunglasses, wood, metal, and bamboo glasses can all be produced in China. Deepwear can help with Manufacturing Eyewear in China. View catalogs of Eyewear manufacturers and suppliers.

FOOTWEAR:

Chinese footwear is one of the most dominant when it comes to Global footwear production and export. China is the largest producer of various categories of shoes like sports shoes, sneakers, leather shoes, sandals, wedding shoes, slippers, mules, etc. In fact, the footwear manufacturing companies in China have always been well established and newer innovations combined with age-old techniques, management practices, and affordable prices have contributed to its success. Chinese factories can offer almost all materials like Leather, PU, denim, canvas, rubber, Synthetic compounds, Cotton, etc. Discuss your needs regarding footwear production in China and get expert insights today.

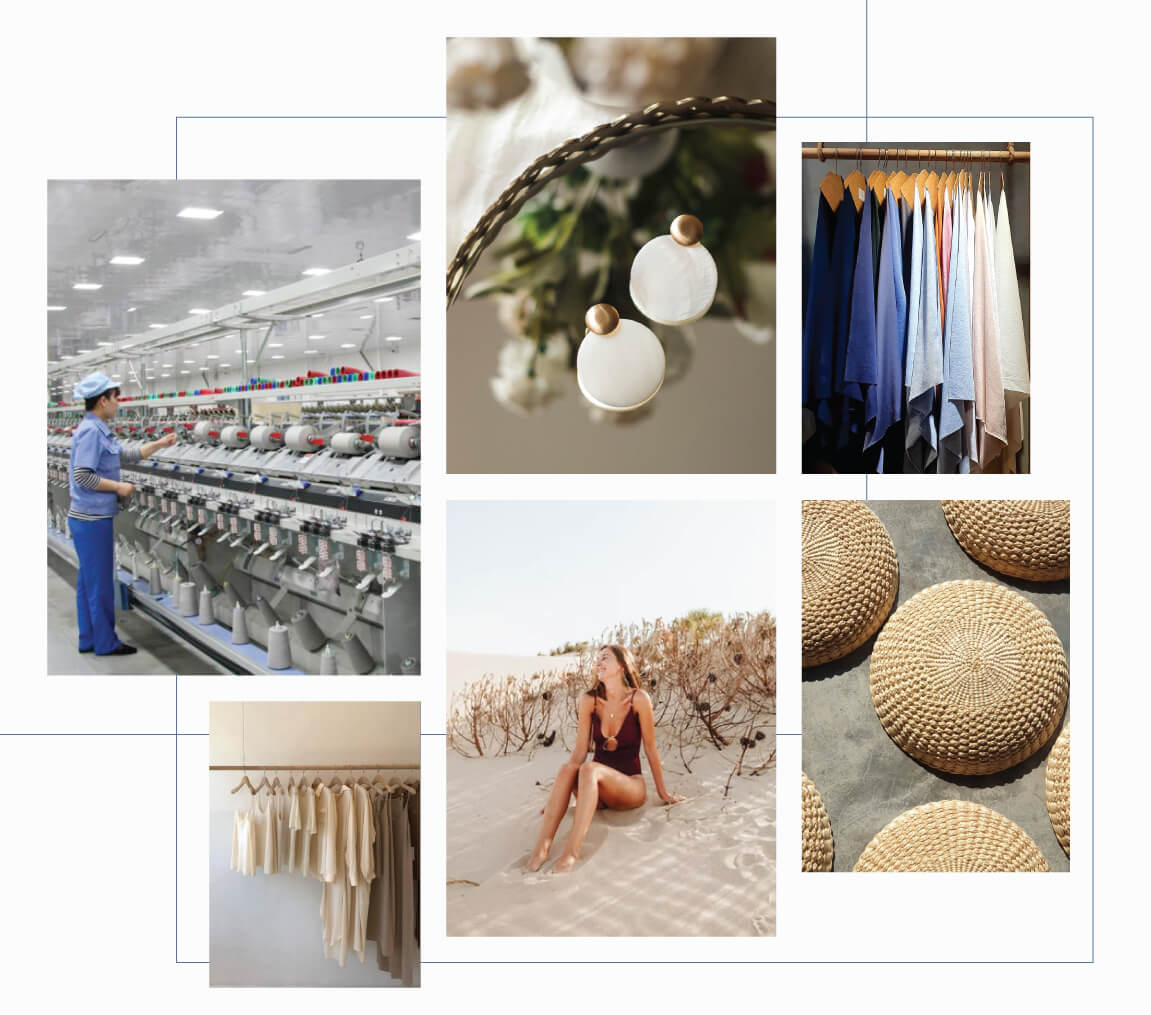

ACTIVEWEAR AND SWIMWEAR:

With China investing a lot of research and development of new technical fabrics, the Activewear and Swimwear industries are a major component of fashion production in China. Major sportswear brands like Nike, Adidas, Puma all have their suppliers in China which speaks volumes about the kind of quality and standard Chinese Activewear suppliers are willing to offer. Also with growing demands for sustainably produced garments, Chinese suppliers offer a variety of options to choose from like recycled polyester made from PET bottles. They also offer a range of casual wear, active-casual wear, athleisure wear, and sportswear. Start your activewear production in China with the right guidance, direction, and insights with Deepwear.

JEWELRY:

China has a huge Jewelry production and Export market. They can essentially any quality of your preference and budget. China is known for its widely produced Machine-made jewelry. They offer custom jewelry designs too, but it is to be noted that the more customizations you ask for the more the prices will increase. They offer all types of jewelry like Stainless steel, Gold, Silver, Plastic, Pearl, Imitation, Children’s jewelry, etc. Another thing when it comes to Chinese jewelry factories is the fact that they are extremely busy and so prefer their customers to have basic knowledge about the product they want to produce since they cannot afford to lose time explaining the production process and other details to the customers. That being said, Since they are so experienced, they can offer excellent and practical solutions to your technical queries if needed. To know more about manufacturing jewelry in China click here.

TRIMS AND LABELS:

Trims and labels are essential to any design project but are components that are often underappreciated or neglected. China is an excellent place to source Trims and Labels. All kinds of trims and labels are possible to be produced in China. All kinds of trims like buttons, zippers, rivets, eyelets, tapes, ribbons, lace, elastics, pins, etc can be easily sourced. Similarly, all kinds of branding components like hang tags, swing tags, care labels, sizing labels, stickers, barcodes can be manufactured in China. Customization is very much possible in China since they require separate molds and China has the technology to produce that.

To understand what all come under trims and labels and to see how to work around them, check out our previous blog on Manufacturing and Sourcing Trims and labels. It is essential to note, that Customizations mean that the factory has to go out of their usual process to produce your products, which means the cost of manufacturing will be high. Check out our Trims and labels factories.

Not just the above-mentioned products, literally every single thing can be manufactured in China, from Diapers to pots, to pins, to bags, to hats, to swimwear, to sunglasses, to rings, to jewelry cases, to belts, and we can also easily find factories and manufacturers who can manufacture packaging for all your products. All kinds of standard and custom packaging options can be found in a variety of materials like paper, cloth, canvas, cardboard, plastic, metal, wood, etc. Check out all the possibilities in terms of Fashion design consultation, manufacturing, sourcing, buying, design, logistics in China.

FASHION MANUFACTURING IN CHINA: ADVANTAGES

DIRECT ACCESS TO RAW MATERIALS

China has direct access to a lot of raw materials and this ensures they are obtained directly from the source avoiding added overhead expenses, transportation costs, and middlemen charges. Since all these costs are omitted, The prices go down which is one of the major benefits of manufacturing in China. The prices of all products in China are much lower than its global competitors. You can get cheap products of good quality in China. Not to lie, but you do get a varying degree of qualities in China, and there are possibilities of encountering cheap quality products, but it is also possible to source and manufacture excellent quality products for nominal prices.

TECHNICALLY ADVANCEMENTS:

China is a global leader in manufacturing, which means it has a well-established manufacturing industrial sector that has decades of experience to back it. Apart from experience, China also is a leader in terms of innovation, research, and development.

LARGER AND EXPERIENCED PRODUCTION POSSIBILITIES

One of the other reasons why China is preferred is because of the fact that larger production orders are possible without affecting the lead time much. Due to the presence of large manufacturing facilities and lower labor costs, you can hire more people to work on a single project, completing it faster.

GREAT SERVICE

Chinese factories are really sweet and patient. They always revert to mails and call requests. They always acknowledge all types of brands be it a small-scale brand or a large company, but it is important to note that the Chinese factories have minimum order quantities (MOQ) which needs to be met for them to work with you. Regardless they are never rude and in fact due to their experience in the Fashion manufacturing sector, They also can provide excellent technical inputs to help you with error-free production. They work with the intent of maintaining long-term relationships with you.

THINGS TO KEEP IN MIND WHILE WORKING WITH CHINESE FACTORIES.

SOURCING A CHINESE FACTORY

One of the biggest reasons why people hesitate to contact or approach China for their fashion manufacturing needs is the fact that it can be a little complicated to find a good factory that matches all your pre-requisites. The market is saturated with millions of factories and to make it even more difficult, there are so many sourcing Agents hired by certain factories to directly lead clients to them. Do your prompt research before trusting anyone with your projects and always ask someone experienced with the Chinese market like Deepwear to assist you and help you choose legitimate suppliers. To know more about how to source a factory click here.

COMMUNICATION

Chinese factories have come a long way in terms of ensuring good communication. Most factories have an official In-house translator in their facility to talk with Clients comfortably. But even then sometimes if the factories don’t have a translator, or you want to give specific instructions to let’s say the technical designer or production manager sometimes your instructions might get modified while translating it. To avoid this, At Deepwear we have our own exclusive office and members in China who can fluently speak Mandarin and English.

It is advised to use as many visual references to help explain your ideas clearly. Nothing is better than having a constant presence on the ground throughout the whole production process from start to the final delivery of the product to make sure everything happens correctly, the way you wanted. Another thing to note is the fact that Whatsapp is not very commonly used in China, and people use Wechat and Skype to communicate. Regardless they are extremely responsive and you can always expect a reply in about 24-48 hours.

SOCIAL STIGMA

Most people associate the “Made in China” label with cheap low-quality products. And as I said earlier, while cheaper low-quality products can be produced in China, it is not the only case. Chinese factories can offer all degrees of qualities all the way from low-quality products to luxury high-end fashion pieces. There are good and bad products in every country and with the right research, experienced guidance, and industry knowledge, you can filter out the good and leave out the bad. Deepwear can help you choose the right factory based on your preferences and can save you from being scammed.

ADDED COSTS

The cost of products is based on a lot of factors like Order quantities, the complexity of the design, added custom elements, etc. It is common knowledge that the higher the order quantity, the lower the price. And the smaller your order quantity the more expensive it can be. Similarly the more custom details you want to add to the design, the cost of the product will keep adding up. Other than that, The cost of Shipping, custom duties, etc also need to be considered. Usually, during sampling, the cost of a sample is much higher than the cost of the product in production.

If you need the products/sample shipped to your country, the cost of shipping to and form needs to be taken into account. This can usually be avoided by having someone trustworthy on the ground, who can assess the products and do a thorough inspection of the products on your behalf. Due to the recent increase in Coal prices, there have been changes in the manufacturing processes in terms of order quantities, lead times, and prices. So it is advisable to do your research and talk about this to your factory before starting the process.

POST-COVID FASHION MANUFACTURING IN CHINA

Pre-Covid era, Chinese factories were very strict in terms of the kind of brands they preferred to work with. But after the whole pandemic, there is been a lot of organizational restructuring in terms of Fashion manufacturing in China. The fashion industry in China had to rethink its strategies and hence started being more open to all types of projects. They are now more appreciative of all orders that come their way since Covid had induced a lot of stigmas around working with China. As the covid situation started becoming a part of the new normal and things started to settle down, A new era of Fashion manufacturing in China can be seen.

SUSTAINABILITY IN CHINA

There are a lot of administrative policies that are being put in place by the Chinese government to pivot towards a more sustainable, greener direction. While the magnanimity of the Chinese fashion manufacturing sector makes it difficult to implement things overnight, steps are being taken to make a difference.

Fashion manufacturers, brands, and consumers have recognized the need to shift towards more eco-friendly and environmentally viable alternatives, due to the rising pollution levels, population statistics, and the decline in resource to people ratio. The public drive to move towards sustainable practices added with government initiatives and consumer demands paint a promising picture in terms of the Sustainability of fashion in China.

Besides that, China offers one of the most advanced and forward infrastructural facilities, which has been positively used to work towards sustainable products, materials, and practices, Sustainable materials, Recycled/upcycled fabrics, biodegradable alternatives, Low carbon footprint options, deadstock options, etc is all available in China. Check our sustainable Chinese factory catalogs.

DEEPWEAR IN CHINA

Deepwear had had a prominent presence in China for more than a decade. Our office in Guanzhou city is strategically located so that all the industrial areas and the wholesale markets are accessible. The advantage of working with Deepwear is the fact that we have an international team with members from all over the world in countries like Australia, Thailand, America, India, Indonesia, Vietnam, Spain, Morocco, Portugal, Turkey, Netherlands, Bulgaria, France, and the UK. Our exclusive local team in China comprising of Chinese team members helps us tap into the best prices and deals and to find the correct conditions in terms of factory selection and research. Discuss your projects and get your production started today.