Constantly living and working inside all major manufacturing countries, the real backstage of the fashion industry for so many years, has been a continuous road of learning and growth. It has been and still is, an exciting and big challenge to develop the team and concept of Deepwear around the world.

Standing right in the factories, working with them from the design and concept, to the final product, whilst being in the runways of the fashion capital cities in order to be well informed about trends, allowed us to have a whole understanding of the fashion world backstage, behind the curtain. We are not a trendy digital website selling virtual promises. We are a real international team with real experience, doing the real work, with the real people, on the real ground.

At Deepwear, we believe in a global Vision and we exist to support, develop and protect your brand. We feel committed to established and experienced companies new and experienced in the industry. That is why we want to share a few important insights that will help you to analyze and reach better conditions, results, and security.

1. Have specific and detailed designs

As most of you know, one of the most important parts and the beginning of any product is the design and layout. Having clear designs ensures that production happens efficiently and more accurately. The more clear and communicative your designs are, the less confusion there is during the manufacturing process. This can be achieved by detailed planning and instructions, with specifications regarding every aspect of your product.

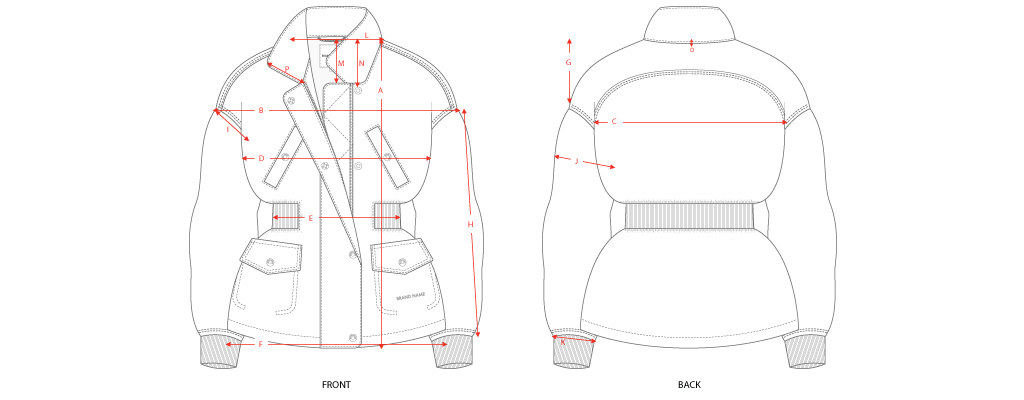

A technical file is the best method to communicate your ideas, validate details, and track progress. It includes a B.O.M (bill of materials), construction, artwork, size grading and even packaging/branding. Not only is it your blueprint for the factory, but it is also your insurance document during the development process.

You do not need to spend your money and time on pattern making. This should be part of the factory’s work. Just make a clear tech-pack and attach a physical sample, even if it is not the sample for that tech-pack. It will serve just as a reference for the quality and level of finishing you require from the factory.

2. Research about Raw materials

Whether you are adding to an existing category or starting something new, knowing what kind of materials you want for your products is extremely important. Communicating the quality, weight, characteristics, sustainability, will help inform what prices, lead times, and availability are possible. In addition to the base materials, it is also important to think about every single component such as the trims, thread color, labels; all of which distinguish the details of your product.

At Deepwear, we have our own 13 offices inside most of the important fashion production and buying countries around the world and our international team is constantly present on the ground inside the factories, sourcing raw materials, coordinating the critical path, and managing the suppliers to find new techniques and possibilities.

We present your project straight to specialists that are adapted to your standards. We are present at the suppliers before the orders, during the whole production, and after the orders. We don’t act as middlemen but as your representative employee, bodyguard and advisor.

3. Know your order quantities and requirements

Before accepting a project, the factories will analyze your order quantities (per style and color), in addition to the total quantity and the frequency of orders. Factories like to have forecasts to be able to organize themselves and evaluate whether your project is financially viable and interesting for them. At Deepwear, we help visionaries convert their concepts and ideas into factory output which is mutually beneficial and balanced.

We work with a large network of workshops, small, medium, and big factories that can start producing from small orders (50 – 200 pcs per style etc) and bigger factories that have higher MOQ.

It is all about matching the right project with the right factory according to the brand’s specific needs and interests. We help bridge the gap between factories and brands to develop a mutually beneficial relationship.

It is also important to highlight that the average quantities will vary on the type of product that is going to be manufactured. Remember that the bigger your order quantity is per style, the lower your prices will be and vice versa. Choose manufacturers with the most compatible offer that really suits your brand.

4. Research factory options

Choosing the right manufacturer is the most important element in this process. Research and analysis ensure that you get the best conditions for your specific requirements and also clarifies what the factory can realistically achieve for your brand.

It is important to finalize the most practical and cost-effective option. In order to achieve that, Deepwear will support you to audit and shortlist factories, communicate and negotiate with them, present and explain your projects, and better help you to understand their capacities, strengths, and weaknesses.

Never just explore one supplier or factory, or settle on the first factory you find. If you are not able to physically source factories yourself, Deepwear can support you by understanding your requirements and provide viable options that are secure for your brand.

5. Check factory background

Working with new manufacturers or suppliers can sometimes be tricky as you do not have first-hand experience with them and you are not on the ground to verify processes in person.

Most manufacturers are open to sharing factory information, pictures, videos, and a list of their production facilities and technology. This step will help you to understand the diverse options you can explore with the factory.

There is no secret. Only by being constantly on the ground with the factories will you achieve professional results and be able to achieve transparency. If you cannot go to the factories physically and monitor the production, you can use a quality sourcing team to inspect the premises. It’s critical to analyze the owner of the factory, the staff and negotiate the conditions and clarify responsibilities.

We at Deepwear are not a middleman, we are not a supplier either. We act as your employee, bodyguard, and advisor from the inside of the production countries. We work for you, and advise brands on how to protect their interest. We know the factories we work with, we have the experience and we are in place, therefore, we can support you to negotiate conditions and prices for you, and with you.

We have developed techniques and strategies that fit all the situations that could arise. We have established a large global network of factories of all specialties, levels, products categories, and a capacity to source worldwide.

6. Communicate things clearly with factory

Many brands face issues at this stage. It is not the easiest to communicate your requirements clearly unless you have someone on the team who is on the spot, knows the local language, values, experience, culture.

As we know, communicating things clearly in terms of your expectations, limitations, and budget is very important. Effective communication is key when bringing your collection to production, so considering what type of questions you might ask and understanding the processes will assist in getting accurate information the first time. Also, make sure to continuously validate if both parties are on the same page to get a realistic and fair deal.

Many companies we work with approach us because they face difficulties implementing solid communication with the factories and this could lead to miscommunications that could result in unnecessary delays and heavy loss and expenses.

This is why our experienced team is an international team, speaking more than 15 languages. On each project, we have locals and international project managers working together.

We know the needs of our customers because we know their territory and standards but we also understand what the factory needs and what they are capable of. Having managed hundreds of projects worldwide, we have developed an understanding of the buying and production countries, and their common language.

Before starting anything with a factory we always establish the communication rules before any collaboration, and these must be agreed on and confirmed by both sides.

During a project, set regular meetings with the factories to keep the communication active. This will also warn you of problems early on before it’s too late, which in turn helps you react better and find efficient solutions.

7. Set a time-frame

Another thing Brands struggle with is making sure they receive the products on time. Setting clear timeframes with the factories and openly communicating with suppliers is vital to ensure everything goes according to the plan. The thing most people fail to acknowledge is the fact that your time frame must be realistic and include some margin for errors. There needs to be some wiggle room for several rounds of sample development, confirming designs, and re-negotiating prices; all of which require time.

Time is the highest value in this industry at all stages. Therefore you will need to plan your schedule very carefully and experience will be beneficial. You will need to have the timing always confirmed by the factories. Responsibilities, warranties, and penalties when suppliers don’t respect their timing agreements should be all clarified at the start with the supplier.

We at Deepwear don’t adapt the time to the project. We plan carefully the timeline of the project and then we adapt the project to the timeline, making sure to always deliver quality. Everything is about time. This also explains why we provide different options of factories for your project. It is also to be sure they don’t waste your time.

Factories know that you have deadlines and sometimes they play with this, so in order to never be dependent on one factory, always have at least 2 factories for the same product category as a safety net. The earlier you start your projects the better it is.

Our Advice for those who don’t know it yet or don’t realize it yet, Do not underestimate the value of time and transform the time into your best friend. With a good experience, well-negotiated contracts with factories, a constant presence inside all the production territories right next to the factories, and organized plannings and checkpoints, you will be able to reach good time management and therefore improve the general results of your projects and established long term collaborations with your clients and factories.

8. Samples

Samples are when things start getting real, you actually see the first translation of your design into an actual product. They are an important part of the manufacturing process and are useful during the pre-production research and the planning stage, but also help to understand things before the final production. They help you establish whether the product matches your designs and expectations or not and what technical improvements or corrections should be added.

It’s normal sometimes to repeat samples until you reach perfection. Normal timing to develop samples is between 2 to 4 weeks, depending on each factory. It is important to remember that samples are usually charged more than the cost of your finished product and this cost should be taken into factor while budgeting and planning to avoid confusion in the end. Negotiations of the sampling conditions with the factories are important to note and clarify.

Advice: You should always develop the same product samples with at least 2 factories as security to compare the workmanship and to never be dependent or blocked by a single factory.

9. Have periodical QCs

Our QC strategy mainly has multiple stages.

- Factory auditing. We ensure we are working directly with the source. IWe evaluate their strengths and weakness. In addition, we evaluate the supplier has ethical and safe working environment and practices, to make sure your project is in the right hands.

We personally audit the factories by physically visiting them, before the actual manufacturing begins. - Sample development

Developing the prototype of your product requires a lot of care and detail. To minimize risks and costs, we inspect each sample that leaves the factories. - Production

We continuously check the products as they pass through the manufacturing process, and lastly, we do a ‘final audit’ to ensure that the products match the designs and expected quality.

While all of these steps help ensure efficient and accurate production, there are numerous roles and factors that a brand has to manage, and outsourcing some responsibilities that don’t require an in-house presence, can help your business achieve greater flexibility, additional perspective, and maximum efficiency. Outsourcing certain processes offer a pool of experienced and qualified professionals available within your budget.

At Deepwear, we are an exclusive international team of professionals from all over the world, on the ground in key locations. We work with carefully selected suppliers, many of which have worked with us for several years. Being strategically positioned in all the major production countries of the world gives us the advantage of easily accessing the factories and physically being there while the products are being manufactured and continuously inspecting them to see if they fit our quality and ethical standards. In the end, there are no secrets. The best way to control processes is to be on the ground with the suppliers.

If you want to know more about our sourcing and production services, contact us here.