A practical checklist for emerging fashion brands to source fabrics confidently. Learn how to define briefs, compare MOQs, test quality, and work with reliable suppliers—with support from Deepwear’s global sourcing teams.

For emerging fashion brands, fabric sourcing isn’t just a technical step — it shapes product quality, costing, sustainability, and your ability to scale. Yet many founders struggle with the same roadblocks: confusing quality differences, high MOQs, inconsistent communication, and long lead times that stall development.

This guide turns the process into a simple, phase-by-phase checklist you can follow, whether you’re sourcing locally or internationally.

In this blog we cover:

- How to clarify your fabric needs before approaching suppliers

- Typical challenges emerging brands face

- Phase-by-phase guidance from brief to production

- Where MOQ ranges, sourcing regions, and budgeting fit into your strategy

- When to bring in expert support from Deepwear

Phase 1: Define Your Fabric Brief Clearly

Before contacting suppliers, clarity is your competitive advantage. A precise fabric brief helps mills quote accurately, reduces sampling rounds, and avoids surprises in costing. Startups often skip this step, which is why they face inconsistent samples or inflated MOQs.

Your checklist:

- Fiber type (cotton, linen, wool, synthetics, blends)

- Weight/GSM and fabric width

- Required finishes (soft, brushed, stretch, moisture-wicking, sheen)

- Sustainability goals (GOTS, OEKO-TEX, recycled content, eco-dyeing)

- End use (dresses, activewear, loungewear, accessories)

- Budget + desired MOQ range

- Physical reference sample for factory analysis for the quality / finish & product application

Our teams often help brands refine their spec sheets during this stage so suppliers interpret the brief correctly from day one.

For a deeper look at the strategic foundations that help small brands grow — from costing to supplier credibility — you can also explore our guide on the seven key factors that influence fashion brand success.

Phase 2: Research & Identify the Right Suppliers

This stage is where many small brands get stuck. Finding suppliers online is easy — finding partners who meet your quality, sustainability, pricing, and MOQ needs is much harder. Effective sourcing blends online research, industry referrals, and on-ground validation to ensure you’re speaking with credible, capacity-ready suppliers.

Your checklist:

- Choose supplier type: mills (custom development), converters (fabric sourcing networks), jobbers (deadstock/low MOQ options)

- Identify sourcing regions based on fabric category (knits, wovens, technical fabrics, artisanal textiles, sustainable options)

- Verify certifications: GOTS, OEKO-TEX, FSC, BCI, or equivalent regional standards

- Compare pricing structures, MOQ signals, and lead times

- Conduct light due diligence: responsiveness, sampling quality, references, production history

Deepwear’s global team regularly evaluates suppliers across multiple regions — ensuring quality, ethical compliance, and realistic MOQs for small brands. To make this even easier, we’ve already created a free, step-by-step guide on sourcing fabrics in India — covering knits, wovens, fabric construction, supplier types, MOQs, and the questions to ask before you commit. We use this same structured due-diligence approach in every sourcing region worldwide.

Phase 3: Sample & Test Fabrics Properly

Sampling is your quality checkpoint. It’s where you confirm whether what you imagined is what the supplier can actually deliver. Small brands often skip testing — which leads to shrinkage, pilling, color fading, or draping issues later in bulk.

Your checklist:

- Order 5–10 yards for meaningful testing and proto creation

- Evaluate weight, drape, stretch recovery, hand feel

- Test colorfastness (wash, rub, sunlight)

- Lab tests (as needed): tensile strength, tear resistance, chemicals, moisture management

- Confirm fabric width and check for selvedge or edge damage

- Track consistency across multiple sample batches if applicable

Deepwear can coordinate lab testing and sample evaluations for clients, helping identify risks early so brands avoid expensive bulk mistakes. Sample fees typically range between 2–4× the fabric cost. Some mills apply separate development fees, which may be refundable only upon confirmed bulk orders. Deepwear will always negotiate favourable terms, but final fee structures are set by the supplier.

Testing Responsibility Reminder: Deepwear advises all brands to conduct their own internal wash tests, stretch tests, and QC checks in addition to any lab testing. Final approval must come from the brand before bulk order.

Phase 4: Compare Costs, MOQs & Lead Times

Once samples pass your tests, it’s time to assess the numbers. Fabric pricing affects everything — including retail pricing, margins, and your ability to scale. This is also where MOQ signals become important: lower MOQs typically mean higher per-meter cost, while mills offering custom development often require higher MOQs due to machine setup expenses.

Your checklist:

- Compare price brackets per fabric type

- MOQ ranges (deadstock, low-MOQ suppliers, custom mills)

- Lead times (stock vs. made-to-order)

- Dyeing and finishing surcharges

- Testing and certification fees

- Freight, duties, and local delivery costs

- Identify the most cost-efficient option that still meets quality standards

Note on Timelines: All timelines provided are standard industry estimates. Actual lead times may vary based on supplier capacity and seasonal demand. Deepwear will communicate delays but cannot control supplier-side timing.

Disclaimer: MOQ ranges mentioned in this guide are indicative. Final MOQs are determined solely by the supplier based on construction, machine setup, and availability. Deepwear can support negotiation, but MOQs are ultimately at the discretion of the mill.

Phase 5: Confirm Production Readiness & Approve Bulk

By now, you have clarity on quality, pricing, and timelines. Approving bulk production should be a calm, structured decision and not a gamble. This final phase ensures that the fabric you receive at production scale is exactly what was sampled.

Your checklist:

- Issue a confirmed PO with detailed specs

- Request a pre-production sample (PPS)

- Reconfirm color standards and lab dips

- Align final MOQ and delivery dates

- Set up quality control checkpoints

- Document all details in your tech pack

- Prepare fabric for cutting, pattern work, and shrinkage allowances

Deepwear facilitates sourcing, communication, and due diligence, but is not responsible for production output, bulk fabric issues, or supplier QC beyond the agreed scope.

If you want help reviewing your fabric options or validating a supplier before sampling, you can connect with Deepwear’s sourcing team here — we guide emerging brands through briefs, testing, and supplier selection from day one.

Challenges & Limitations Emerging Brands Should Expect

Even with the right process, sourcing comes with industry-wide constraints. New brands should be prepared for:

- High MOQs for custom developments

- Limited flexibility during peak seasons

- Price inflation for low-MOQ orders

- Longer lead times for eco-certifications

- Dye/finish variation between sample and bulk

- Restricted access to premium mills without confirmed volume

- Mills prioritising repeat orders over new brands

How Deepwear Helps Emerging Brands Navigate These Challenges

While these sourcing challenges affect the entire industry, the right partner can significantly reduce risks and make the process smoother for emerging fashion brands. This is where Deepwear’s structure, on-ground presence, and decades of sourcing expertise provide a clear advantage.

Deepwear’s Strategic Advantages in Global Fabric Sourcing

- Decades of fabric sourcing and manufacturing experience

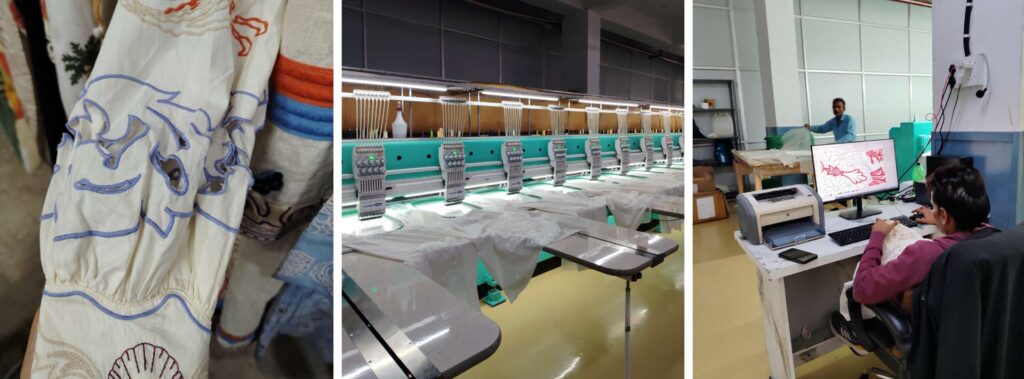

Our founder, Thoray D’Haese Sacoor, brings decades of experience working with mills, factories, and global fashion brands. His sourcing knowledge helps small brands make confident decisions, avoid costly mistakes, and access credible suppliers from day one. - Offices located inside top fabric-producing regions

Deepwear teams are based directly inside major textile hubs across Asia and beyond. This on-ground presence allows real-time supplier checks, faster sample comparisons, and accurate market insights — all essential for brands that need reliable and transparent fabric sourcing. - Direct access to the largest fabric market in the world

Our newest China office sits inside the biggest fabric market globally, giving Deepwear immediate access to mills, converters, jobbers, and updated pricing. This ensures clients can explore more options, find realistic MOQs, and discover fabrics that are not visible through online searches.

With this infrastructure, Deepwear helps emerging brands overcome sourcing barriers, reduce risk, and secure high-quality fabrics with greater speed and confidence.

How Can Emerging Fashion Brands Source Fabrics More Efficiently in 2026?

Emerging brands can streamline fabric sourcing by creating a clear fabric brief, comparing MOQ signals, testing samples properly, and choosing suppliers based on both capability and consistency—not just price. Understanding testing requirements, lead times, and region-specific strengths helps avoid costly mistakes. Deepwear supports brands with on-ground supplier checks, sample evaluations, and realistic MOQ negotiation across key sourcing hubs.