One of the biggest challenges that you will face as a clothing brand owner is finding the right fabric supplier. With so many options available in the market, it can be difficult to know where to begin your search. However, India is one of the leading countries in textile production, making it a great option for sourcing fabrics.

In this blog, we will explore different fabric qualities such as knit, woven, yarn dyed, and printed, and various methods for knitting, weaving, and printing. We will also cover an overall guide on how to source fabrics for clothing lines in India, so you can create that high-quality clothing that your customers will love!

What is Fabric Sourcing?

Fabric sourcing is the process of identifying and selecting the right fabrics. It involves finding and evaluating potential suppliers, negotiating prices and terms, and ensuring that the chosen fabrics meet the required quality, color, texture, and other specifications.

Fabric sourcing is an important part of the textile and fashion industries, where the quality and appearance of fabrics play a critical role in the success of a product. It involves researching the latest trends and materials, as well as understanding the manufacturing process, environmental impact, and ethical considerations associated with different types of fabrics.

Fabric sourcing can be done through a variety of channels, such as visiting trade shows, attending fabric mills and suppliers, working with agents and intermediaries, or conducting online research. The ultimate goal of fabric sourcing is to secure the right fabrics at the right price while ensuring that they meet the requirements in terms of quality, performance, and sustainability.

THE BASICS OF FABRIC CONSTRUCTION

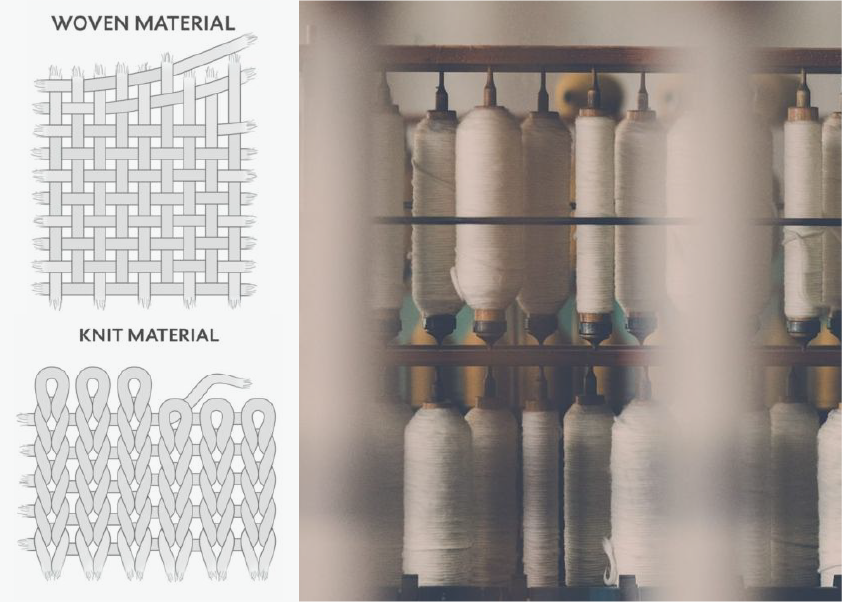

A key aspect of the design process is understanding the structure of the fabric and determining which type of fabric is most suitable for the product being created. There are various methods of fabric construction, but knits and wovens are two of the most frequently utilized.

KNITTED FABRIC

Knitted fabrics are often favored for their lightweight and comfortable feel, as well as for their low maintenance, as they are less prone to wrinkling. These fabrics are a popular choice for designing soft, comfortable tops, pants, and lingerie due to their stretchy properties, and are also ideal for athletic wear. Currently, knitted fabrics are available in a range of fibers such as linen, silk, wool, Tencel, polyester, cotton, and blends of cotton.

There are two primary methods of creating knitted fabrics:

- A weft knit or hand-knitted fabric is constructed by continuously looping a single yarn to form horizontal rows. Each row builds upon the previous one.

- A warp knit is produced using multiple parallel yarns that are interlaced vertically to form the fabric. This process occurs simultaneously.

WOVEN FABRIC

Woven fabrics are produced by interweaving two or more sets of yarns in a perpendicular manner, using either a handloom or power loom. It is known for its non-transparency, toughness against wear and tear, and ability to resist pilling. The quality and strength of woven fabrics are proportional to their thread count – a higher count implies better quality and strength. Woven fabrics are widely used for making denim and dress pants, button-down shirts, and jackets.

Woven fabrics are classified into two categories:

- Basic weaves: These include simple patterns such as plain weave, twill weave, and satin weave.

- Complex weaves These feature intricate designs such as dobby weave, jacquard weave, and pique weave (as seen in men’s polo shirts), among others.

TYPES OF FABRIC SUPPLIERS

Securing dependable fabric suppliers is an important aspect of launching a clothing brand. It’s important to find partners who can assure the availability of the necessary stock and timely delivery.

There are three distinct categories of fabric suppliers that differ in their operations and the type of fabrics they offer.

Fabric Mills: Offer custom-made fabrics and typically have substantial minimum order quantities (MOQs).

Converters: Companies that buy unfinished or raw fabrics from fabric mills and then process the fabrics by dyeing, printing, or washing.

Jobbers: Usually stock a limited selection of leftover fabrics from converters and mills. They may sell these fabrics at discounted prices and may not restock a fabric, color, or print once it has sold out. Be cautious when dealing with this type of fabric supplier, as repeated orders for the same fabric may not be possible.

Contact DEEPWEAR Manufacturing Services

SOURCING FABRIC: WHERE TO FIND THE RIGHT FABRICS IN INDIA FOR YOUR CLOTHING LINE?

Sourcing fabric for clothing lines in India requires careful consideration of both fabric quality and cost. Different regions of India offer a variety of fabrics at varying prices. Here are some popular options to consider:

Delhi and Delhi-NCR: If you’re looking for regular quality fabrics for clothing such as 80s voile, 60s cambric, 40s poplin, and more, Delhi-NCR is a great place to source at a cheaper rate. Delhi-NCR also has mills like Gupta Exim, Richa, and Mercury knits that offer good capacity for knitting fabrics. Additionally, fabric showrooms in Delhi-NCR are a great option for garment sample development and small fabric orders.

South India (Salem and Erode): If you’re looking for yarn-dyed fabrics at a cheaper price, the South region, like Salem and Erode, is a great option. This region also offers various woven and industrial fabrics, as well as beautiful hand-spun Kanjivaram sarees.

Tirupur: This region is the hub for knits fabric sourcing.

Surat: If you’re looking for any kind of polyester fabric, Surat is the hub in India, although there are also some mills in Delhi-NCR that produce polyester fabrics.

Jaipur: Jaipur is a great place to source hand-block printed fabrics and hand-crafted textiles.

Mills: Many garment exporters source greige fabrics and then have them dyed or printed at a local mill to save on costs. Sourcing materials for clothing from organized mill sectors like Arvind, Vardhman, Nahar Industries, BVM, and Bombay Rayon offers higher-quality fabrics but at a slightly higher price. These mills are located in different parts of India, with Arvind Mills located in Ahmedabad, Gujarat, and Vardhman in Ludhiana, Punjab.

When sourcing fabric in India, it’s important to weigh the trade-offs between cost and quality to find the right solution for your clothing line. CONTACT DEEPWEAR INDIA

SOURCING FABRIC: QUESTIONS TO ASK YOUR FABRIC SUPPLIER

Sourcing the best fabric for a clothing line is crucial and requires careful consideration. A spec sheet is a helpful tool for listing specific information about each fabric quality and can be created by the brand or provided by the supplier. Here are 10 questions to ask suppliers during the sourcing fabric process:

- Fabric Article or Item Number: This number is used by the supplier to identify each fabric quality and can be found on the fabric hanger. Take note of this number for samples and bulk orders.

- Fabric Weight: Consider the weight of each garment being designed, as it can affect draping and fit. Fabric weight is listed in grams per square meter (GSM), and examples of common weights for different types of knitwear are provided: 200-300 GSM for activewear, 180-250 GSM for lounge pants, 130-180 GSM for standard t-shirts, and 130 GSM or less for lightweight t-shirts. These are guidelines and may vary for your clothing line.

- Fabric Lab Testing: This is a process of testing the physical and chemical properties of a fabric to ensure that it meets the required quality and safety standards. There are several different types of fabric lab testing, including physical testing (such as tensile strength and tear resistance), chemical testing (such as pH and formaldehyde content), and performance testing (such as abrasion resistance and moisture management). This can help to identify any potential issues or defects in the fabric that may affect its performance or appearance.

- Fabric Construction: The process of converting yarns or fibers into fabric and determining its characteristics through the materials and methods used, such as weaving or knitting.

- Fabric Width: The measurement of the fabric roll from edge to edge, provided by the supplier with two points of measurement: the total width and the cuttable width. The cuttable width measures any skewing or damage to the edges of the fabric during production and transportation.

- Fabric Price: The cost per yard or meter of fabric can differ from year to year based on market conditions and the cost of resources. To stay within budget, determine a target price for each fabric based on your target retail price for the garments and the fabric yield. Buying fabric in bulk is usually more cost-effective than purchasing sample yardage, which can be $3-$5 more per yard, or even double the bulk price. Ask the supplier for their sample and bulk pricing.

- Minimum Order Quantity (MOQ): The minimum amount of fabric yardage required per order from a supplier can vary from supplier to supplier. The MOQ for sample yardage is typically five yards, while bulk MOQs can be higher. The supplier may offer to apply the bulk MOQ across multiple colors of the same fabric quality or require it per fabric, per color. If you’re unable to purchase 500 yards of one color, for example, consider maximizing your buying options by applying the MOQ across more than one color.

- Fabric Delivery Lead Time: The fabric delivery lead time is the period from the moment you place your order to the delivery of the fabric at your factory. Some suppliers have stock available, leading to a quick delivery time, while others may have a lead time of 4-8 weeks. You can ask the supplier for delivery lead times for both sample and bulk yardage. In most cases, sample yardage has a shorter lead time.

- Country of Origin (COO): The country of origin is the location where the fabric is produced and shipped from. It’s important to know this information for the labeling requirements of your garments, and it can also impact the cost of your fabric.

- Fabric Care Instructions: The instructions provide recommendations for washing and caring for a specific fabric based on its content and construction. Different fibers may require different care, such as avoiding high heat or dry cleaning. These instructions are provided to ensure the longevity of your fabric.

SOURCING FABRIC WITH DEEPWEAR

With all these tips on how to source your fabric in India, Deepwear is here to make it easier for you. Deepwear can be your fabric-sourcing agent. With a large network of Indian fabric manufacturers and an on-the-ground team ready to serve you, you can be sure to get the best quality fabric at the best price. Our team has years of experience in the fabric industry and has built strong relationships with leading fabric suppliers for small businesses and established brands. We understand the challenges involved in sourcing fabric for your clothing line and will work tirelessly to ensure that you get what you need when you need it.

With Deepwear, you can be sure that your fabric sourcing is in good hands. Our team is always on the lookout for the latest fabric trends and innovations, and we bring this expertise to every project we work on. From basic to complex fabrics, we will help you find the right fabric for your clothing line and make sure that you are always ahead of the curve.

And if you already have existing designs, we can also assist with that. We can help develop and improve your collections, from fabric selection to manufacturing and production. We can help you streamline your production process, improve your product quality, and increase your overall efficiency.

So why wait? Partner with Deepwear today and experience the ease and peace of mind that comes with working with a clothing-sourcing agent. We look forward to helping you bring your clothing line to life! Contact us today!