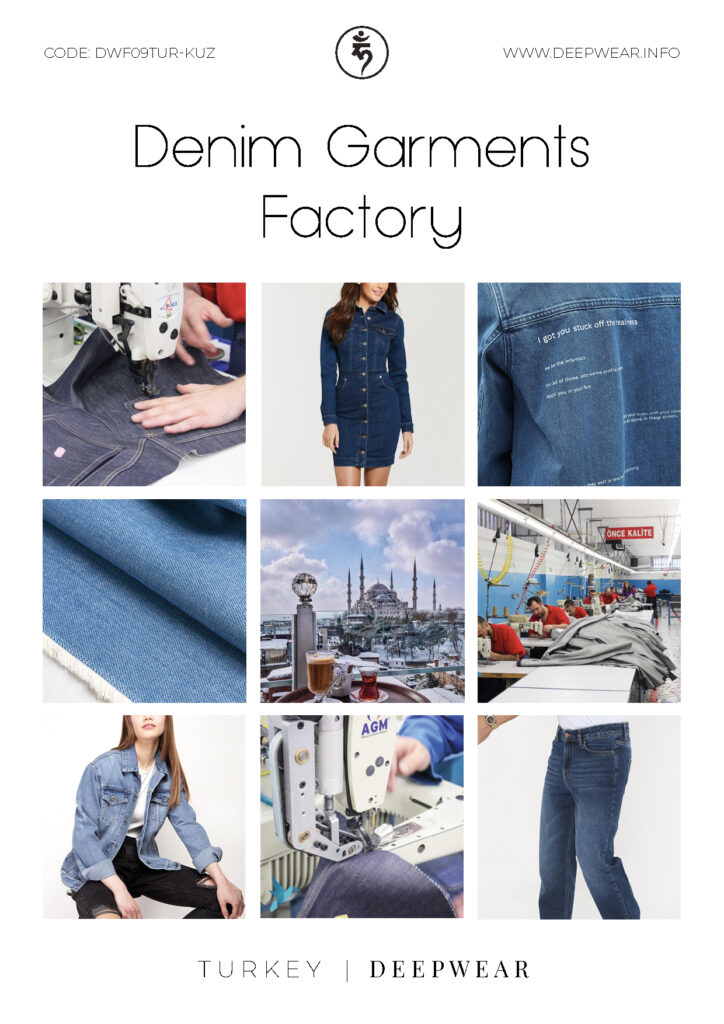

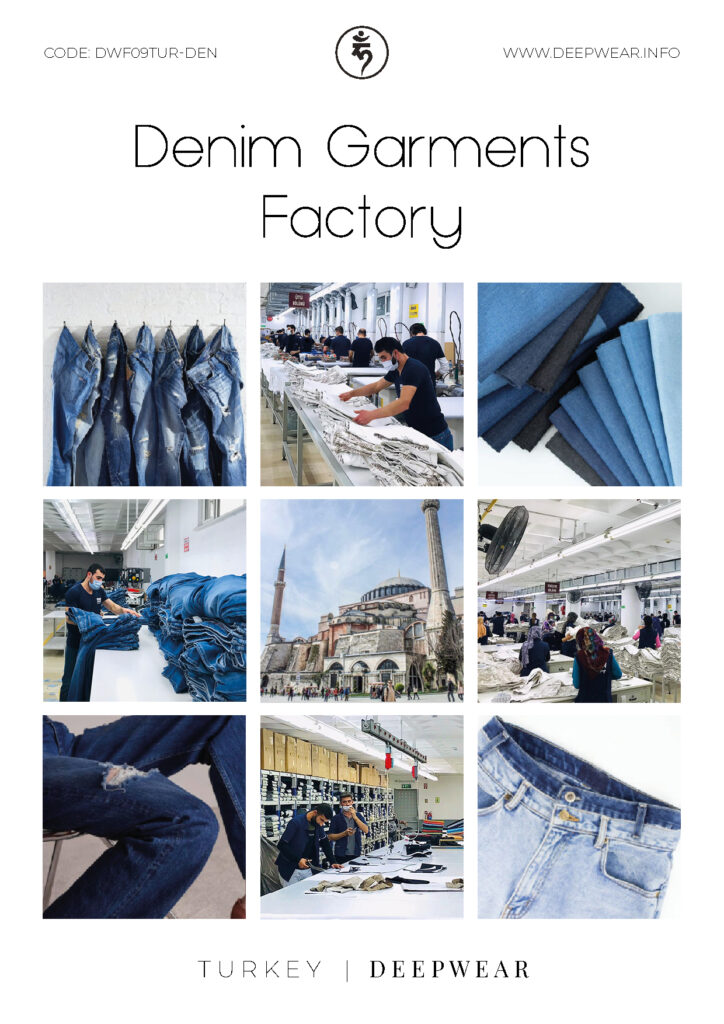

Denim Production and Manufacturing Hub in Turkey

In today’s global economy, more and more companies are looking to outsource their denim production to places like Turkey.

Denim is a popular commodity in Turkey, and companies that specialize in sourcing denim from this country can help you find the perfect supplier for your needs.

In this blog post, we’ll explore why denim is such a famous choice in Turkey and how a sourcing company like Deepwear can assist you in finding the perfect denim supplier. DEEPWEAR TURKEY

Why Turkish Denim?

Denim is a sturdy cotton twill fabric that is most commonly used to make jeans and other denim garments. Turkish denim is some of the most sought-after denim in the world, and it has been used by top designers for years. There are several reasons why Turkish denim is so highly prized.

First, Turkey is renowned for its naturally shining, luminous texture, and durable cotton fibers. In addition, with the countries’ strategic geographical positioning between two major continents – Europe and Asia – Turkey has built a formidable denim industry of outstanding quality.

Moreover, Turkish denim mills use the latest technology to produce superb-quality fabrics, and they are constantly innovating to create new styles and textures. Fabrics and integrated fabrics are mostly produced in several provinces in the country such as Istanbul, Bursa, Adana, Denizli, Kahramanmaraş, İzmir, Gaziantep, Tekirdağ, and Uşak.

And although more expensive than their counterparts in Asia, Turkish manufacturers can also offer several advantages, including depth understanding of up-and-coming trends, faster delivery times, and the flexibility to make changes to existing designs.

This flexibility is essential in today’s fast-paced fashion market, where trends can change quickly and consumer demand is notoriously unpredictable. While Turkey’s higher production costs may be a deterrent for some buyers, it’s still preferred compared with the Far East and can be offset by the benefits of exceptional quality of denim, minimum order quantity, shorter timelines, and faster response times.

As a result, denim fabric exports for many of the world’s notable denim brands are mainly produced in Turkey.

How Is Denim Made In turkey?

Today, denim production is a complex process that involves a number of different steps.

Step 1: Cotton cultivation

The denim fabric production process begins with the cultivation of the cotton plant. As a protective measure, cotton plants develop thick fibers around their small black seeds as they grow. Once separated and spun into threads, these materials can then be woven together to create a denim fabric.

Step 2: Processing into yarn

Cotton fibers are transformed into denim fabric through a complex process of combing, spinning, and treating the yarn. From raw material to finished product, an array of washes, dyes, and treatments are applied that give each piece its distinct look.

Step 3: Final production

Once the cotton yarn is dyed, it is now woven into bolts of unique warp-faced denim style. This fabric is then cut down to size for use in creating stylish consumer denim garments.

How much does denim fabric cost?

Cotton is one of the most inexpensive natural fabrics, and it is even comparable in price to cheap artificial fibers like polyester and rayon. It also doesn’t cost that much extra to create denim fabric from cotton yarn, which puts denim fabric in the middle range of fabric prices.

Generally speaking, most denim jeans manufacturers will require at least 300 to 500 pieces per style and color to start production. Fortunately, many companies offer discounted prices for large orders; however, one can expect a minimum wholesale unit price for a single pair of jeans to range between $13 and $30 per unit. It’s worthwhile to note that with more energy-efficient machines being used and production methods improving, it’s now possible to reduce the number of pieces.

But, even if a smaller production order will certainly be more convenient for those willing to invest in Turkish denim, it has also increased the costs involved due to the amount of labor and precision required. In addition, those looking for lower minimum order quantities can take advantage of private label collections from denim garment manufacturers. These collections are designed with the latest trends in mind and provide an easy way to create your own signature look with minimal effort.

Some types of denim, however, can be very expensive. For example, raw, organic denim can cost dozens of dollars per yard, and cotton products made sustainably and ethically are typically more expensive. However, it’s worth the investment since consumers are increasingly searching for safe and organic textile products, which provide more profits in the long run.

Another factor that might affect the price of denim jeans fabric is its weight The most commonly used metric to judge denim thickness is ounces per yard (OZ). The OZ measurement typically ranges from 4-16, with heavier denim usually being more expensive than lighter ones; but, there does seem to be a correlation between the OZ rating of a product and the price.

This idea is rooted in the fact that it takes about twice as much fabric to make a 12OZ pair of jeans compared to an 8OZ pair. Considering that fabric for clothing isn’t cheap and all OZ ratings offer different levels of strength, durability, and quality of look, it makes sense why there would be a connection between increased OZ ratings and increased cost.

What are the different types of denim fabric?

Over the years, various denim fabrics have been developed. Here are some of the most popular options:

Raw denim

Raw denim is a unique type of jeans that takes 6 months to 1 year of regular wear in order for it to really take shape. For those who can’t wait, some enthusiasts have found an extreme substitute: storing their jeans overnight in the freezer. Not only does this rid them of unnecessary microbes and bacteria – but also gives new shape.

Sanforized denim

Sanforized denim offers a softer fit and feel, but they aren’t as personalizable as raw denim jeans. And despite being less durable than its counterpart, sanforizing has revolutionized the fabric we now recognize as modern-day denim – transforming it into coveted fashion staples around the world.

Stretch denim

This type of fabric is composed of a blend between cotton and spandex or another similar material. It creates an ultra-flexible fit that’s perfect for stylish skinny jeans and other tight-fitting wardrobe staples.

Crushed denim

This type of denim is an eye-catching fabric that feels like velvet. Its unique crinkled look adds a cool, wrinkle-free texture to jackets and skirts for easy everyday style.

Selvedge denim

Selvedge denim has become a fashionable choice for outerwear, famed not only for its strength and durability but also the fringe at the end. Jackets crafted from this fabric have experienced a surge in popularity due to their longevity and timeless style.

Acid-wash denim

This type of denim is one of the most recognizable fashion statements around, with its mottled look. It’s crafted by subjecting raw denim to a strong acid bath that strips away just enough dye for an interesting effect.

Poly denim

Denim has long held a debate on what actually makes something ‘true’ denim. While traditionalists firmly believe that authentic denim can only be made with 100% cotton, the popularity of poly-fiber types of denim keyed up by leading fashion brands suggests otherwise. Polyester and other artificial fibers such as lyocell or nylon are often added to cotton blends in order to create this modern take on classic jeans – aptly named “poly denim.”

How Do Turkey Denim Manufacturers Apply Sustainability in Denim Production?

The last two decades have seen a surge in producer and consumer interest in sustainable and responsibly produced products, with organic cotton being a prime example.

This trend is particularly notable in Turkey which has identified organic cotton as a key component of its sustainable denim manufacturing strategy.

This means that manufacturers are now producing denim jeans fabric made from organic (and mostly locally sourced) cotton, helping to minimize their environmental impact while also providing valuable support for Turkey’s agricultural community. As more companies transition to using organic cotton material, it is believed that the Turkish denim industry will be able to scale up production while simultaneously reducing its environmental impact.

Contact Us Today!

In conclusion, there are many reasons to choose Turkish denim for your next product line.

So, if you’re looking for a denim partner in Turkey, Deepwear is here! With our office located in Istanbul, our on-the-ground team is ready to serve you and bring your vision to life.

We can connect you to the best denim fabric suppliers in Turkey that offer a wide range of high-quality denim fabrics at competitive prices. In addition, these denim suppliers also provide value-added services, such as fabric development, garment construction, and jeans washes.

Our team has also years of experience working with high-end brands and designers who want to incorporate organic cotton into their sustainable denim production. We also provide our clients with expert advice on how to reduce their carbon footprint while remaining profitable.

Contact us today to learn more about Denim Jeans Manufacturers in Turkey and how they can benefit your business.