Can zero-waste fashion truly scale globally? Discover the challenges, opportunities, and how Deepwear helps fashion brands turn sustainability into scalable, actionable change.

The fashion industry is one of the world’s largest polluters, responsible for massive water consumption, chemical use, and mountains of textile waste. Policies and initiatives have begun to address this—but the results so far are uneven, fragmented, and, in many cases, nascent.

Scaling zero-waste fashion production globally may seem like a herculean task. Textile waste piles up in the global south, while fashion giants continue churning out more clothes. Some brands claim to use recycled materials, but critics argue much of this is greenwashing. Processing non-virgin materials often requires more energy and resources than starting with new ones, creating a paradox: trying to be sustainable can sometimes amplify environmental impact.

The COVID-19 lockdowns offered a glimpse of a “better normal”—wildlife returned, pollution decreased, and even the ozone layer showed signs of recovery. Yet, as restrictions lifted, consumption and production quickly rebounded, often at higher rates than before. The fashion industry, in particular, doubled down on its fast-paced, resource-intensive model.

In this blog we cover:

- The environmental impact of the fashion industry and why zero-waste fashion production is critical.

- The key challenges brands face when scaling zero-waste methods globally.

- Opportunities in the circular fashion economy and how Deepwear supports brands in achieving sustainability.

- Practical steps brands can take now to prepare for a zero-waste future.

Why Scaling Zero-Waste Production Is So Difficult

The idea of a zero-waste fashion industry sounds simple in theory: produce responsibly, recycle everything, and eliminate waste. But in reality, the global fashion system is deeply complex. Each step, from fiber sourcing to final assembly, is intertwined with economic pressures, consumer habits, and technical limitations that make true zero-waste production extremely challenging to achieve at scale.

- Complex Supply Chains: Fashion relies on multiple layers—farming, spinning, dyeing, cutting, and assembly. Redesigning each step to eliminate waste is challenging.

- Material Limitations: Recycled fibers can be lower quality, making them harder to work with and sometimes requiring more energy to process.

- Economic Pressure: Brands compete to produce more, faster, and cheaper, which conflicts with slower, zero-waste methods.

- Consumer Behavior: Overconsumption drives demand for new garments, limiting the impact of zero-waste strategies.

Opportunities in a Circular Fashion Economy

There’s growing momentum toward circularity in fashion. According to a 2025 Boston Consulting Group report, strengthening reuse and recycling systems could boost material recovery to 30% and unlock more than US $50 billion in raw-material value each year. These changes show that circular strategies aren’t just environmentally necessary—they’re economically viable.

Here are five major opportunities shaping this transition:

- Policy and Regulation as Catalysts

Europe leads the charge with regulatory frameworks that make circularity not just idealistic, but mandatory. The EU’s upcoming mandates on textile collection and extended producer responsibility (EPR) are set to accelerate innovation across sorting, fiber recovery, and resale. With the region already generating 29% of global textile-recycling revenues, these policies demonstrate how strong governance can push sustainability forward. - Technological Advancements in Recycling

AI-driven sorting systems and chemical fiber regeneration are transforming what’s possible. These innovations reduce contamination, increase fiber purity, and make true closed-loop recycling more achievable. The global market for next-generation recycling machinery is projected to grow from US $4.1 billion in 2024 to US $6.2 billion by 2034, signaling investor confidence in the future of circular production.

- Economic Value in Material Recovery

Circular systems aren’t only about ethics, they’re also smart economics. Recovering and reusing textiles could unlock billions in resource value while reducing dependence on virgin materials. For brands and manufacturers, this means mitigating supply-chain volatility and cutting long-term production costs through efficient material recovery loops. - Local Innovation in the Global South

In countries like Kenya and Ghana, social enterprises and designers are creating local circular solutions: upcycling discarded garments and reimagining waste as value. Informal workers also extend textile lifecycles through repair and resale. However, these ecosystems face challenges from the influx of imported waste, revealing the need for fairer global systems that don’t offload pollution onto vulnerable regions. - Brand–Manufacturer Partnerships for True Impact

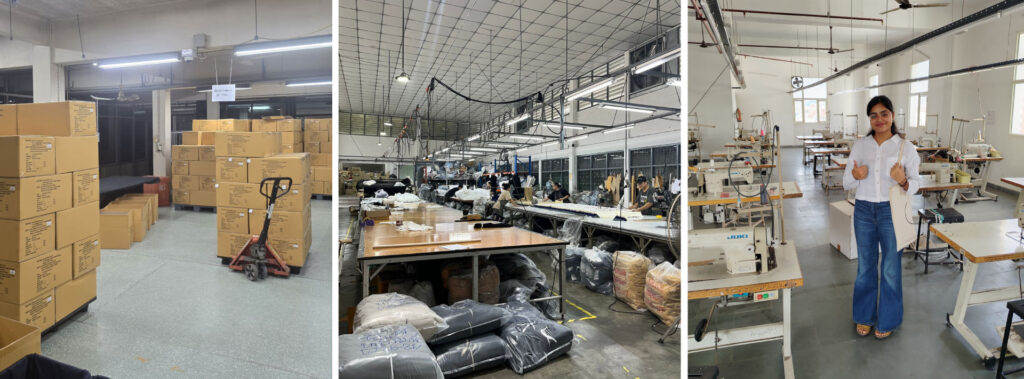

No single actor can achieve zero-waste production alone. Collaboration between brands, sourcing agencies, and factories is essential to scale progress. This is where Deepwear plays a key role helping fashion brands:

- Reduce pre-consumer waste through precise sampling, lean production, and transparent sourcing.

- Integrate sustainable materials and local supply chains to minimize carbon footprints.

- Experiment with circular models, such as modular design, repair services, and limited-run collections.

While full zero-waste production may not yet be globally scalable, the groundwork is being laid. For Deepwear, this shift reflects our ongoing commitment to helping brands turn sustainability into action. We focus on building honest, practical pathways toward circularity—reducing waste, improving efficiency, and designing systems that make responsible production achievable at scale. Through collaboration and innovation, we continue to guide our partners toward a future where sustainability and scalability truly coexist.

Looking to reduce textile waste and transition toward circular fashion? Deepwear’s consultants can help you map out zero-waste strategies—from material sourcing to factory collaboration—tailored to your brand’s goals.

How Brands Can Prepare for a Zero-Waste Future

The next decade will test whether fashion can truly decouple growth from waste. As new recycling systems, stricter regulations, and circular business models emerge, brands that adapt early will have a clear advantage. Those that continue relying on linear, take–make–dispose systems risk falling behind—not just environmentally, but commercially.

To stay competitive, brands should:

- Audit their supply chains to identify waste hotspots and set measurable reduction targets.

- Explore regional manufacturing to shorten transport distances and minimize carbon impact.

- Collaborate with sourcing experts who understand both sustainability and scalability.

- Invest in materials innovation—from biodegradable fibers to regenerated textiles.

At Deepwear, we help brands bridge the gap between vision and reality. Our team can support zero-waste initiatives from concept to production: optimizing design, sourcing sustainable fabrics, and connecting you with trusted manufacturers across Asia, Europe, and beyond. Whether you’re rethinking your supply chain or testing circular models, we help you build responsibly from the start.

What Is Zero-Waste Production in Fashion?

Zero-waste production means designing and manufacturing garments without generating textile waste—through pattern efficiency, recycling, and closed-loop systems. Deepwear helps fashion brands implement these practices globally, connecting sustainable materials, ethical factories, and circular design strategies.

Scaling Change, One Partnership at a Time

Zero-waste production is not guaranteed to become the global norm overnight. The path forward is uncertain, and the fashion industry faces structural, economic, and behavioral hurdles that cannot be ignored. If brands and manufacturers fail to reduce their carbon footprints and address waste responsibly, the consequences are shared by all: rising greenhouse gas emissions, polluted waterways, overflowing landfills, and the further degradation of ecosystems—particularly in regions already burdened by imported waste.

At Deepwear, we believe waiting is not an option. Every decision to rethink sourcing, optimize production, and adopt circular practices brings measurable progress. Our sourcing expertise, sustainable manufacturing network, and transparent approach empower partners to move from intention to implementation—step by step, collection by collection.

Ready to take your next step toward a circular, zero-waste fashion model? Book a strategy call with Deepwear’s sustainable sourcing experts or explore our global network of ethical and circular manufacturing partners today.