Learn what deadstock fabric is, its environmental benefits, and how fashion brands can use it responsibly. Deepwear helps you source, verify, and scale sustainable textile reuse globally.

The fashion industry faces a significant environmental challenge, with global textile waste now exceeding 92 million tonnes per year, according to the Un Environment Programme (UNEP) This alarming statistic underscores the urgent need for sustainable practices in fashion production. One promising approach is the use of deadstock fabric sourcing—unused or surplus textiles from previous production runs. By repurposing these materials, brands can reduce the demand for new resources and minimize waste. However, to truly make a positive impact, it’s crucial that brands adopt responsible sourcing and transparency practices when utilizing deadstock fabrics.

In this blog we cover:

- What deadstock fabric really means and how it differs from recycled materials.

- Why deadstock matters for both sustainability and brand creativity.

- Practical steps for responsible sourcing and production using deadstock.

- How Deepwear helps brands find, verify, and integrate deadstock fabrics efficiently.

What is Deadstock Fabric?

Deadstock fabric refers to textiles that remain unused after a production run, often due to overproduction, cancelled orders, or unsold inventory. These materials can include:

- Mill overruns: Excess fabric produced beyond the original order

- Colour-lot leftovers: Remaining fabric from specific dye lots.

- Sample yardage: Fabric used for prototypes or samples.

- End-of-bolt: The final portion of fabric on a roll.

It’s important to distinguish deadstock fabrics from recycled or upcycled textiles. While recycled materials are processed from existing products, deadstock fabrics are unused, often virgin materials that were never incorporated into finished goods.

Why Deadstock Fabric Matters — Environmental + Commercial Benefits

As global textile waste continues to rise, sustainable textile reuse present a rare opportunity for brands to reduce waste while keeping their creative and commercial edge. These are unused or surplus textiles from mills or cancelled orders—high-quality materials that might otherwise go to waste. With the fashion industry generating over 92 million tonnes of textile waste every year, using what already exists is one of the most immediate and measurable ways to make production more sustainable.

If your brand is considering a shift toward eco-conscious fabric sourcing, you may also like our related post: How to Distinguish a Real Sustainable Sourcing Company, which explores how transparency and global partnerships can make a measurable difference in reducing waste and impact.

- Environmental Benefits: Repurposing deadstock fabrics helps reduce the pressure on an industry already struggling with overproduction. According to Textile Exchange’s Materials Market Report 2025 (via USB Certification), global fiber production rose from 125 million tons in 2023 to 132 million tons in 2024—more than double the level recorded in 2000. If this growth continues unchecked, the figure could reach 169 million tons by 2030, threatening the sector’s ability to meet global climate targets. The textile supply chain remains heavily dependent on fossil-based synthetics, with polyester accounting for 59% of all fiber output, and 88% of that derived from non-renewable sources. While the production of recycled polyester increased from 8.9 to 9.3 million tons between 2023 and 2024, its global share remains modest at around 12%. Recycled fibers overall account for just 7.6% of total production, and less than 1% comes from pre- and post-consumer textile recycling. In this context, using deadstock fabrics becomes an immediate, practical way to reduce reliance on virgin fiber production. It makes use of materials that already exist—sidestepping the emissions, water use, and chemical impact associated with manufacturing new textiles. Although not a substitute for systemic reform, repurposing deadstock contributes to slower resource depletion and helps brands take a tangible step toward responsible production while larger recycling technologies and certifications continue to scale.

- Waste Diversion: Every roll of deadstock fabric repurposed is one less roll heading to landfill. Considering the millions of tonnes of textile waste produced globally each year, integrating these materials into design pipelines actively supports a circular fashion economy, keeping materials in use longer and reducing the pressure on disposal systems. For a closer look at how sourcing smarter can contribute to circularity, read our feature An Introduction to Sustainable Fabrics, which highlights practical pathways for eco-conscious textile sourcing.

- Commercial & Creative Benefits: Beyond sustainability, deadstock fabrics unlock distinct creative and commercial advantages. They often include premium textiles or discontinued colorways unavailable elsewhere, giving brands access to exclusive materials that elevate storytelling and market differentiation. Collections made from deadstock can be positioned as limited editions, appealing to consumers who value both uniqueness and responsibility. They also allow brands to run small-batch tests before committing to large-scale production—ideal for new launches or emerging labels.

- Market Growth: According to a 2024 report by Market Intelo, the deadstock fabric market is valued at approximately $1.43 billion and continues to grow, reflecting the rising demand for sustainable textile solutions. This growth highlights not just a trend, but a broader shift toward sourcing models that combine environmental awareness with commercial sense. At Deepwear, our 17-country network and on-ground teams help brands identify, verify, and source deadstock fabrics efficiently, transforming what was once excess into new creative potential. To explore how we can help your brand turn surplus into strategy, book a strategy call or see how we apply local expertise in our blog What Makes a Fabric Truly Summer-Ready? Breathability, Design & Smart Sourcing.

Looking to integrate verified deadstock fabrics into your next collection?

How Brands Can Use Deadstock Fabric Responsibly

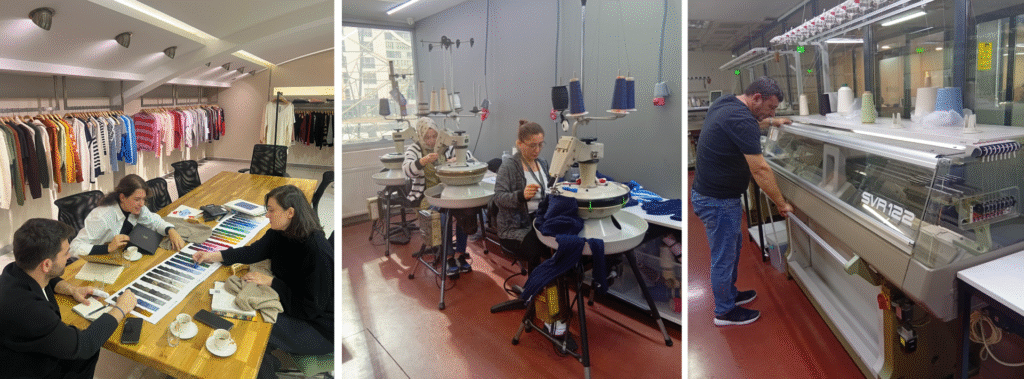

Using deadstock fabrics responsibly requires careful planning, from sourcing to production and messaging. Our teams at Deepwear can help brands leverage this opportunity effectively thanks to our extensive network of mills and suppliers. This gives brands easier access to high-quality deadstock and ensures smooth logistics, verification, and sourcing at scale.

- Procurement & Vetting: Brands should verify the origin of fabrics, requesting when possible, mill documentation for fiber content, dyeing processes, and chemical finishes. Physical inspection of rolls is also important to check for defects, shrinkage, or inconsistent composition. Deepwear’s local teams streamline these checks and can consolidate small lots from different suppliers to create cohesive batches suitable for production.

- Design & Production: Designing with deadstock fabrics requires flexibility. Patterns should maximize roll usage and accommodate varying widths or prints. Deadstock is ideal for capsule collections, limited runs, or premium limited edition garments — creating unique, one-of-a-kind pieces that stand out in the market. Deepwear helps brands plan these small-batch productions efficiently, mitigating the challenges of limited yardage and single dye lots.

- Transparency & Consumer Messaging: Communicating openly about deadstock fabrics is essential. Brands should disclose why fabrics are limited and highlight sustainability benefits without overclaiming. Care and composition labels help consumers understand and maintain the garments. With Deepwear’s experience, brands can tell a compelling story about responsible sourcing while maintaining authenticity and trust.

- Circularity & End-of-Life Planning: Designing for durability and repair extends the life of garments, maximizing the positive impact of using deadstock fabrics. Where possible, take-back programs or partnerships with fiber-specific recycling facilities ensure that materials remain in a circular system, closing the loop on production and waste.

Looking to integrate deadstock into your next collection? Our local teams ensure quality verification, batch consolidation, and on-ground support so your brand can scale responsibly — without compromising creativity. Learn more about our sustainable sourcing solutions.

What Are the Benefits and Challenges of Using Deadstock Fabric in 2025?

Deadstock fabrics reduce waste and resource use while offering unique creative potential. However, they can’t always be reproduced and may require extra verification for quality and safety. Deepwear helps brands manage these challenges through verified sourcing, small-batch planning, and transparent supply chain strategies.

A Creative Path Toward Circularity

Deadstock fabric presents a meaningful way to reduce waste and extend the life of existing textiles — but it isn’t a cure-all for fashion’s overproduction crisis. The truth is, the only way to truly curb textile waste is for large-scale producers to slow down and for governments to strengthen regulations that discourage mass manufacturing and destruction of unsold stock.

That said, deadstock remains a practical and inspiring solution for conscious designers. It’s not limited to “new” surplus rolls; today, we see creative reuses across categories — from deadstock denim to deadstock kimonos and even wedding gowns, to name a few. These transformations prove that any fabric, once considered waste, can find new purpose through thoughtful design and craftsmanship.

If more brands begin to embrace this kind of circular thinking, the industry can move closer to a model where creativity and responsibility coexist, one garment at a time.

Ready to transform deadstock into design opportunity? Book a strategy call with Deepwear’s responsible sourcing consultants or explore our global sustainable textile network today.