Discover how wearable exoskeletons are redefining mobility and accessibility in 2025. Deepwear connects innovation with inclusive, ethical, and scalable wearable tech manufacturing.

In recent years, the demand for assistive devices and wearable exoskeletons has surged, driven by the need to enhance mobility, rehabilitation, and independence for people with physical disabilities. From helping stroke survivors regain walking ability to supporting the elderly in maintaining mobility, these innovations are transforming lives by offering practical solutions for movement, posture, and physical strength.

However, despite remarkable technological advancements, access remains a critical challenge. High costs — with advanced exoskeletons priced anywhere from USD 10,000 to over 80,000 — and limited availability in developing regions prevent many individuals from benefiting from these life-changing devices.

This is where Deepwear steps in. With global manufacturing networks and on-the-ground expertise in key production hubs,we can connect innovation with accessibility, ensuring that wearable assistive technologies can be developed, sourced, and assembled responsibly and efficiently.

In this blog we cover:

- The growing demand for wearable exoskeletons and assistive devices.

- Why accessibility and affordability remain global challenges.

- How Deepwear’s regional expertise bridges tech innovation and production.

- Key sourcing hubs in China, Vietnam, India, Thailand, Turkey, and the U.S.

- The future of inclusive, sustainable wearable technology.

The New Era of Assistive Device Manufacturing

Assistive devices are tools or equipment designed to support individuals with disabilities, improving their ability to perform daily tasks. Wearable exoskeletons are a specialized type of assistive device — robotic or motorized suits worn on the body to enhance strength, mobility, and endurance.

It’s important to distinguish between two main categories:

- Mechanical supports: Devices like posture-assist frames, braces, or crutches that provide stability and aid movement without motors or sensors.

- Powered robotic exoskeletons: Full or partial-body wearable robots that actively assist walking, lifting, or joint movement through motors, actuators, and sensors.

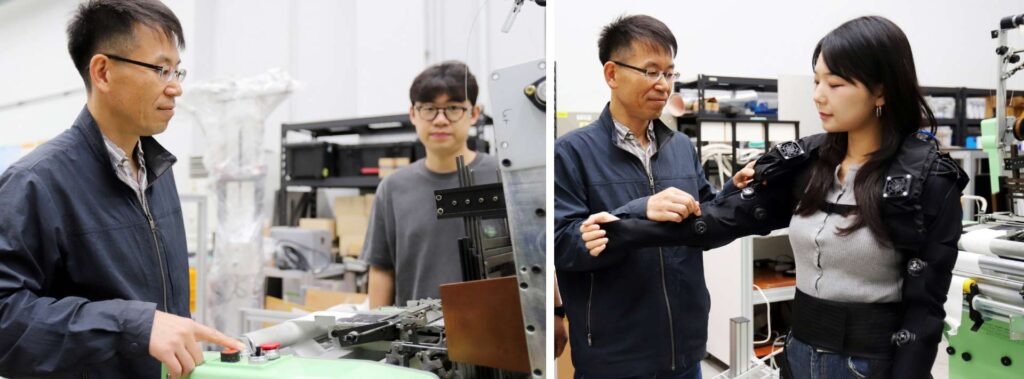

While many people assume that advanced assistive devices are primarily developed in high-income countries, Asian innovation is proving this is far from the case. For instance, in Deepwear’s home HQ country of Thailand, researchers at Chulalongkorn University have developed the Exoskeleton Wheelchair, a hybrid device that allows users to sit, stand, and walk. This project demonstrates that assistive robotics innovation and manufacturing isn’t just a distant dream for countries in Asia. Thailand, while relatively wealthy in the ASEAN context, still offers accessibility and affordability that make such innovations practical and scalable for local communities.

Using lightweight carbon fiber, carefully engineered hip and knee motors, and ergonomically designed joints, the “Thai Iron Man” integrates human anatomy with robotics to improve mobility for people with reduced movement.

While advanced exoskeletons like this can cost thousands of dollars, more affordable alternatives are emerging across Asia — typically around USD 100–300. These lower-cost devices often resemble sophisticated crutches or leg braces rather than fully powered exoskeletons. Users should be discerning, as these options provide limited assistance and are generally most useful in combination with professional physical therapy.

Looking to make wearable assistive technology more accessible and scalable? Deepwear’s consultants can help bridge innovation with real-world impact—connecting your brand to responsible manufacturing partners across Asia and beyond. Explore our services here.

Global Hubs for Exoskeleton Sourcing

When it comes to exoskeleton sourcing and wearable robotics production, choosing the right manufacturing hub determines both cost and performance.

Deepwear’s international network helps brands find the best regional partners for quality, scalability, and compliance.

Disclaimer: The following are average cost ranges for high-end exoskeleton devices and wearable assistive systems. Actual costs may vary depending on complexity, certification, and production volume.

1. China: China leads global assistive device manufacturing, especially for robotic and sensor-integrated exoskeletons.

- Estimated Assembly Cost: USD 1,000 – 8,000 per unit

- Why source here: Ideal for complex builds with integrated electronics, strong robotics infrastructure, and high-volume production capability.

- Things to note: Labor costs and quality vary widely; supplier vetting and QA control are essential.

2. Vietnam: Vietnam is a fast-growing hub for wearable technology assembly with strong expertise in soft materials and ergonomic design.

- Estimated Assembly Cost: USD 800 – 4,000 per unit

- Why source here: Competitive labor costs, skilled manufacturing, and excellent coordination through Deepwear’s Ho Chi Minh City office.

- Things to note: Some electronic components may still need importing from China, Japan, or Korea.

3. India: India offers affordable and flexible production for assistive device manufacturing, suited for early-stage design and prototyping.

- Estimated Assembly Cost: USD 700 – 3,500 per unit

- Why source here: Cost-effective prototyping with a large, skilled workforce and growing tech-manufacturing capacity.

- Things to note: Advanced sensors and medical-grade components may require sourcing from specialist suppliers.

4. Thailand: Thailand is a rising hub for medical-grade manufacturing and clinical testing, backed by strong healthcare infrastructure.

- Estimated Assembly Cost: USD 900 – 5,000 per unit

- Why source here: Excellent for certified or clinical devices, with Deepwear’s Bangkok HQ enabling local coordination and trials.

- Things to note: For advanced robotics components, hybrid sourcing from China or Vietnam is often most efficient.

5. Turkey: Turkey bridges Asia and Europe, providing fast logistics and access to EU markets for wearable robotics production.

- Estimated Assembly Cost: USD 1,200 – 6,000 per unit

- Why source here: Strategic location, solid mechanical manufacturing, and efficient EU distribution supported by Deepwear’s European team.

- Things to note: Labor costs are higher than in Asia, but balanced by faster shipping and certification access.

6. United States: The US sets the benchmark for regulated medical exoskeletons and high-end rehabilitation systems.

- Estimated Assembly Cost: USD 8,000 – 60,000+ per unit

- Why source here: Ideal for R&D, clinical-grade production, and FDA-certified testing supported by Deepwear’s US coordination office.

- Things to note: Costs are high; best suited for specialized production or pilot runs before scaling to Asia.

Not sure which country best fits your wearable robotics production? Let Deepwear help you identify the right manufacturing hub for your cost, quality, and certification needs. Schedule a consultation with us.

Accessibility and Affordability: Bridging the Gap

Despite remarkable progress in wearable robotics, the cost of innovation remains one of the greatest barriers to accessibility. High-end medical exoskeletons, often used in hospitals or rehabilitation centers, can cost anywhere from US$10,000 to over US$100,000 — a price range far beyond what most patients or smaller clinics in developing regions can afford.

While simpler assistive devices are emerging across Asia, they tend to be mechanical or semi-powered, designed mainly to support posture or prevent muscle atrophy. These can range from US$100–3,000, making them far more affordable, but their functionality is limited; often supporting movement rather than restoring it. True mobility assistance requires a combination of motor precision, ergonomic design, and adaptive software, all of which drive up production costs. Yet, cost is only one side of the challenge. Infrastructure gaps, such as limited access to clinical expertise, maintenance services, and certification support, make sustainable adoption difficult in low- and middle-income countries.

Meaningful innovation, therefore, must go beyond engineering excellence. It calls for collaboration among governments, healthcare providers, and manufacturers — creating systems that make assistive technologies part of everyday rehabilitation, not luxury imports.

What Are Wearable Exoskeletons and How Are They Changing Mobility in 2025?

Wearable exoskeletons are robotic suits designed to enhance or restore movement, empowering people with disabilities and supporting rehabilitation. In 2025, they’re becoming more affordable and inclusive thanks to innovations in lightweight materials, localized sourcing, and ethical production. Deepwear helps brands and institutions scale these technologies responsibly through global manufacturing networks.

Technology That Moves Us Forward

Wearable exoskeletons represent more than progress in robotics — they symbolize the fusion of empathy, science, and design. Whether it’s a Thai-built hybrid wheelchair or an open-source exoskeleton blueprint from the U.S., each innovation reflects a shared vision: a world where mobility, independence, and dignity are accessible to all.

At Deepwear, we celebrate this intersection of sustainability, inclusivity, and innovation. As a global sourcing partner, we help brands and institutions transform ideas into tangible products that empower lives — one wearable device at a time.

Ready to bring inclusive, life-changing technology to market? Book a consultation with Deepwear’s global sourcing experts or explore our wearable robotics and assistive manufacturing network today.