There are two main components of swimwear manufacturing: the design process and the actual manufacturing process. Despite being such a small and simple garment, swimwear can be highly technical. This complexity arises from considerations such as fabrics, patterns, design, techniques, cuts, silhouettes, manufacturing, finishing, and hygiene. Let’s explore how to simplify swimwear manufacturing. For detailed discussions on swimwear manufacturing, sourcing, buying, or designing, contact us.

MARKET RESEARCH

To build a sustainable business model, it is crucial to understand the reasons behind your actions. Why are you designing swimwear? Why would clients like them? Answering these questions requires studying and understanding your target market.

Key Questions

- Who are you selling to?

- What do they like?

- What is their lifestyle like?

- What problems do they face?

- What are their expectations with swimwear?

- What is their expendable income?

You can conduct market research in various ways, depending on your approach and what your target market might appreciate. Surveys, social media, direct conversations, and online forums can provide valuable insights. If your initial brand idea includes swimwear products, survey people who fit this category to understand their preferences and priorities. This research will help you set price points and identify market competitors.

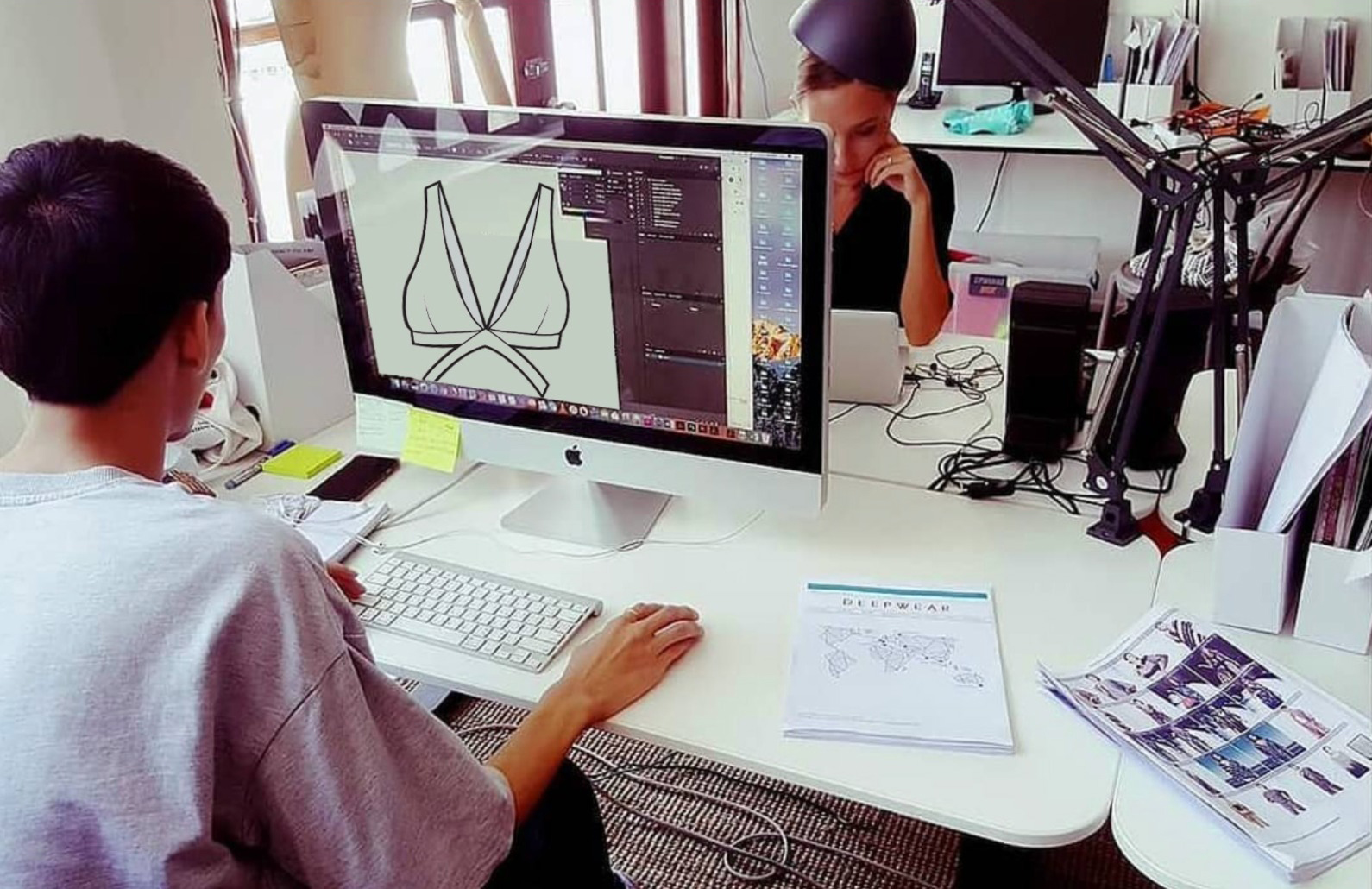

DESIGN RESEARCH

Once you have a clear idea of your target market, your design research becomes more efficient.

Competitor Analysis and Trend Research Understanding what your competitors offer in terms of categories, styles, sizes, colours, design options, and services can provide clarity on how to proceed. Also, consider the season and year you are catering to. Look at what’s trending, conduct fashion trend forecasts, and gather industry insights. Stay informed about the latest improvements in your category.

Ideation and Sketching

Start noting down your ideas and making rough sketches. If you need help understanding the market and swimwear design trends, Deepwear can provide experienced industry insights, consultation, and design services. If you need support with understanding the market and swimwear design trends, we offer experienced industry insights via consultation and design services.

FABRIC SOURCING

One of the biggest distinctions between swimwear and regular apparel or lingerie is the fabric. Swimwear fabrics can be technical and difficult to finalize. The biggest requirement for swimwear fabrics is shape retention. When selecting swimwear fabrics, consider various factors such as comfort, weight, stretch, durability, quick drying, fiber content, and elasticity.

It is important to understand your needs for the swimwear. Do you want to make professional swimwear costumes? Swimwear for people who swim a lot and intensely? Or for people who like to lounge and tan? If the fabrics are for swimming more, they must resist saltwater and chlorinated water. If for lounging or tanning, they must not fade after exposure to sunlight.

WHAT TO LOOK FOR WHEN SOURCING SWIMWEAR FABRICS

Stretch: Swimwear fabric needs to stretch across the body both horizontally and vertically. Finding a 4-way stretchable textile is important for both the main fabric and linings.

Resiliency: This property ensures the fabric’s quality and durability. Cheap or poor-quality swimwear fabrics lose shape after one or two years. A higher recovery rate or resiliency allows the fabric to stretch well and return to its original state after each use.

SWIMWEAR FABRICS

Nylon

Polyamide, or Nylon, is commonly found in swimwear pieces. Nylon resists water and dries quickly, making it a great choice. Swimwear made with Nylon is comfortable and flattering. With the right blends, the fabric can be stretchy and figure-hugging, a desirable quality for swimwear. The subtle gloss and sheen associated with Nylon are interesting to work with.

Polyester

Polyester is known for its soft feel, comfort, durability, water resistance, and quick-drying tendencies. It has an innate resistance to UV rays and is not easily affected by Chlorine. Polyester is great not just for swimwear but for any garment worn by the pool or at the beach.

Elastane

Elastane, also known as Lycra or Spandex, is a completely synthetic material made of Polyurethane. It enhances the elasticity of swimwear materials and is also used for trims.

Polybutylene Terephthalate (PBT)

PBT is a plastic compound with stretchy properties. It has a comparatively stiffer feel with a light and soft touch. When treated with a dull or matte finish, PBT can move without resistance in the water, making it an excellent choice for competitive swimwear pieces.

SUSTAINABLE MATERIALS:

Incorporating sustainability in swimwear can be challenging. Most good swimwear fabrics have a synthetic composition to make them more durable, water-resistant, and chlorine-resistant. However, one way to introduce sustainability is by using recycled materials like recycled polyester. While not 100% sustainable, it’s a start. Sustainable swimwear fabrics are rare but not impossible to find.

Cotton

Before the invention of synthetic compounds, natural fabrics like cotton or wool were used for swimwear products. Cotton is comfortable, soft, and lightweight but not ideal for swimwear because it retains moisture, making the garment extremely heavy when wet. Cotton is still a great option for resort/leisurewear, cover-ups, and sarongs, but not for swimwear.

Hemp

Hemp is an excellent option for sustainable swimwear fabrics. It is much more sustainable compared to most natural fabrics. Hemp is durable, strong, and resistant to UV rays. It is pest-resistant and does not leak toxins or microplastics into the water.

Econyl

Econyl is a sustainable option for brands that prefer a nylon base for their swimwear production. It takes nylon from landfills and upcycles it into new products, retaining the quality and properties of nylon. The unique aspect of recycling nylon is that it can be recycled infinitely if constructed correctly.

Repreve

Repreve is a fabric made from recycled PET bottles. Although synthetic, its recycled nature makes it a comparatively eco-friendly swimwear fabric. It reduces the use of additional petroleum products and aims to circulate pre-existing ones, contributing to a sustainable lifestyle.

Limitations of Sustainable Swimwear

When using plastic-based synthetics, tiny particles of microplastics can leak into the water, especially during washing. Natural fabrics, on the other hand, often cannot mimic the performance of synthetic compounds. Recycled plastic and polyester fabrics have gained popularity as they strike a balance. Using recycled materials helps remake products out of existing plastic rather than virgin plastic. However, the scalability of these materials is low, making it easier for smaller startups to adopt them, while large-scale adoption remains challenging. Currently, few facilities specialize in recycling recycled fabrics, so while they extend the product’s life, they don’t completely avoid eventual landfills.

Incorporating natural materials like cotton for cover-ups and scarves, ethically sourcing swimwear, and ensuring transparent manufacturing are sustainable practices. Sustainability in swimwear is complex, and it’s important to decide which aspect to focus on. Doing something is better than doing nothing.

Swimwear Trims

Swimwear trims are crucial for design and production. While choosing efficient swimwear fabrics is essential, trims also significantly impact the garment’s durability and comfort. Using non-water-resistant, chlorine-resistant, or corrosion-free trims can reduce durability and comfort.

Lining

Adding lining to swimwear fabrics prevents transparency and sticking to the body when wet. It’s important to choose a fabric that matches well with the shell fabric. If the outer fabric is very stretchy, using a non-stretchy lining can distort the garment and make it uncomfortable. Power mesh is commonly used as swimwear lining.

Elastic

Elastics of ⅜” and ¾” are commonly used for swimwear, while wider elastics are used at the waist for swim trunks. It’s essential to check the durability, water resistance, and chlorine resistance of the elastic. Rubber-based elastic that doesn’t react with chlorine is typically used for swimwear.

Boning

While not compulsory, additional structures like underwires, boning, and stays in swimsuits can improve the garment’s fit. Boning on the side seam gives better structure and prevents buckling.

Technical Designs

Having a good technical specification sheet is crucial since swimwear is a category where small mistakes can compromise the garment’s fit and fall. The tech pack must include details like fabrics, design elements, measurements, trims, prints and colours, seams and stitch lines, labels, tags, packaging and folding instructions, and size grading. It serves as a reference point during quality control to ensure consistency and minimize errors. For help with creating detailed and error-free tech packs, contact us.

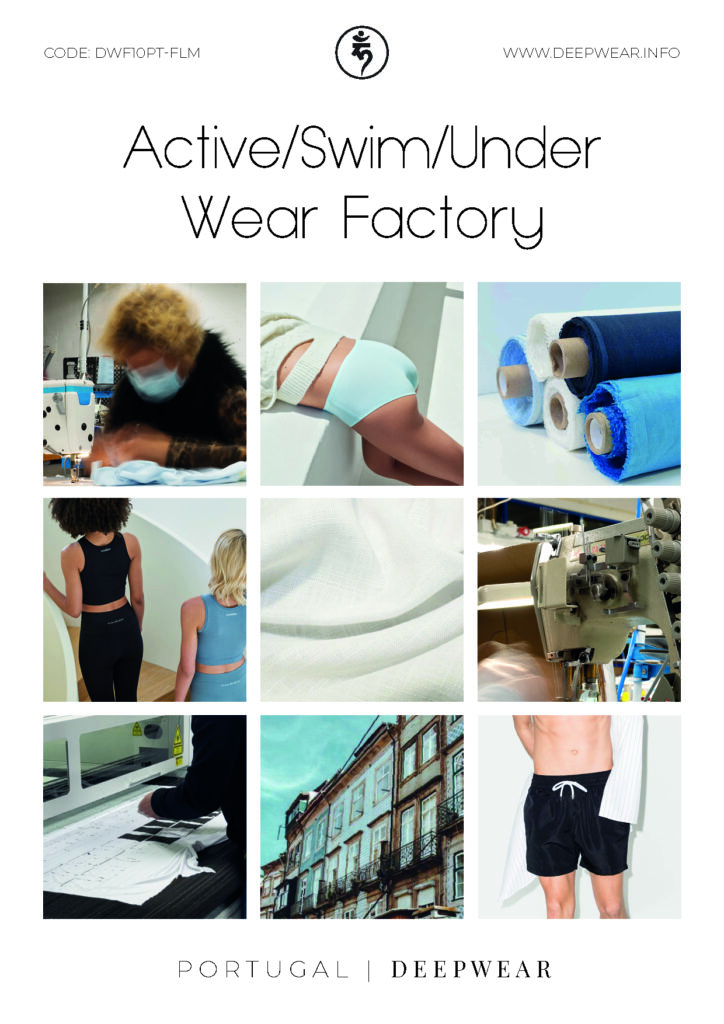

SOURCING SWIMWEAR FACTORIES

When searching for swimwear manufacturers, you must consider several factors. First, decide whether you want to manufacture your products overseas or domestically.

Overseas suppliers can be affordable, but managing a long-distance relationship solely through calls can be challenging. Miscommunication and information loss are common. To make overseas manufacturing work, clearly communicate your goals, quality requirements, and timelines with the supplier. Establish a clear communication medium, and consider being on the ground to avoid scams. Deepwear can assist with overseas manufacturing, as we have exclusive teams in prominent swimwear production countries like China, Portugal, and Thailand.

Working with domestic manufacturers can simplify communication, but your options will be limited to what is available locally. Both options have advantages and disadvantages, depending on your goals and needs.

Avoid producing in Bali. Although popular with Instagram brands, Bali lacks efficient infrastructure and raw material imports. Our Bali office helps brands transition their manufacturing to other countries like Thailand, China, Portugal, Türkiye, or Vietnam with minimal losses.

Pricing

The price of your product depends on various factors such as desired quality, fabrics, trims, order quantities, and customizations. The more complex your design, the higher the price. Custom elements like buttons and pins add to the cost. On average, swimwear production can range from $9 to $20-$30+ per piece, with custom gemstones or premium materials escalating the price.

Minimum Order Quantities

Most factories have a minimum number of products they can produce. This means your order quantity cannot be smaller than that, although this number is negotiable depending on the type of order and designs. Note this number and be sure about the range you are comfortable with. Typically, the higher your order quantity, the lower the price per piece. At Deepwear, we advise producing around 300 pieces per style for favourable conditions, but we can accommodate lower and higher quantities based on your preferences.

Categories and Capabilities

Not all factories excel in all categories. Some specialize in specific types of swimwear. For example, one factory might excel in women’s swimsuits, while another excels in swim trunks. Determine what you want to produce to help shortlist factories. Also, check the techniques the factory can handle. Some have in-house embroidery or printing facilities, while others outsource these services.

With Deepwear, you can source factories that cater to your specific needs, such as MOQs, fabric types, techniques, location, timeline, and other social requirements like sustainability and ethical manufacturing. We establish clear lines of communication with factories and help you stick to your plans. To learn more about Deepwear’s sourcing services, click here.

Swimwear Manufacturing and Quality Control

Once the tech packs and factory sourcing are done, swimwear manufacturing can commence. A prototype is made first to ensure the product matches your designs or to identify necessary changes. This stage is crucial for making corrections. Conducting a thorough check during this stage is essential. Having someone physically inspect every stitch, measurement, and fabric quality is indispensable but challenging with overseas suppliers. Deepwear can help with detailed quality checks and manufacturing services. Click here.

White Labelling

Many factories offer pre-made collections with no branding or labels that can be purchased by fashion brands. These collections can then have small customizations and be rebranded to fit the brand’s direction and aesthetics. This is called white labelling. If you are looking for white-label options and private-label swimwear manufacturers, Deepwear can help you create a cohesive collection tailored to your requirements. Send us your requirements and book a consultation today.

Branding and Packaging

Swimwear branding and packaging are crucial because they ensure that all your hard work and effort are conveyed to the clients. You can extend your inspiration to custom packaging elements. Whether you prefer natural, sustainable, reusable, or biodegradable packaging options, Deepwear can help. Our in-house graphic designers can design packaging for you. We also assist with designing and producing tags and labels for your products.

For more information on branding and packaging, send us your queries at enquire@deepwear.info.