Introduction

The swimwear and activewear markets are experiencing remarkable growth, fueled by consumers’ increasing focus on health, wellness, and sustainable living. The core of this surge lies in the innovation and selection of fabrics. These materials are not just the backbone of garment design but pivotal in enhancing performance, ensuring durability, and promoting environmental stewardship.

As consumers become more discerning, the demand for apparel that balances functionality with eco-conscious production has risen sharply. This shift has placed a spotlight on the critical role of fabric choice, pushing the industry towards better materials. Materials that offer a blend of comfort, technical performance, and sustainability. And indeed, these industries are evolving rapidly. Therefore, understanding the significance of fabric technology and its impact on manufacturing processes has never been more important.

This article serves as a gateway to exploring the intricate relationship between fabric selection and the booming swimwear and activewear sectors.

Understanding Swimwear Manufacturing

Swimwear manufacturing intricately combines fashion with functionality, creating garments designed for aquatic environments. The industry prioritizes fabrics that resist chlorine degradation, retain shape, and offer UV protection, catering to the diverse needs of water sports enthusiasts and casual beachgoers alike.

Recent trends have steered this sector towards sustainability. There is an increased emphasis on eco-friendly materials such as recycled polyester and organic cotton. Additionally, technological advancements have introduced high-performance features. Examples include quick-dry fabrics and enhanced durability, meeting the consumer’s demand for swimwear that is both stylish and practical.

This shift towards innovation and sustainability reflects a broader change in consumer attitudes. A change with a growing preference for products that align with ethical and environmental values. As swimwear manufacturers navigate these evolving trends, the importance of fabric selection in shaping the future of the industry becomes increasingly evident. Thus revealing the need for materials that deliver on quality, performance, and sustainability.

Exploring Activewear Manufacturing

Activewear manufacturing has transcended traditional boundaries, blending high-performance functionality with the latest fashion trends. This sector demands fabrics that support a wide array of physical activities, necessitating features such as moisture-wicking, breathability, and stretchability.

The growth of the activewear market is propelled by a cultural shift towards more active lifestyles, coupled with the rising popularity of athleisure wear as a fashion statement. Manufacturers are responding with innovative fabric solutions that enhance athletic performance while ensuring comfort and style. The development of smart textiles, incorporating temperature regulation and odor-resistant technologies, is setting new standards in activewear.

Moreover, the industry is moving towards more sustainable practices, exploring eco-friendly materials and production techniques to reduce environmental impact. As activewear continues to evolve, the focus on fabric technology underscores the sector’s commitment to meeting the dynamic needs of consumers, combining functionality, style, and sustainability in every garment.

The Role of Fabrics in Swimwear and Activewear

Fabric selection is critical in swimwear manufacturing, directly influencing a garment’s performance, durability, and wearer satisfaction. When choosing fabrics for swimwear, manufacturers must prioritize several characteristics. For example, stretchability, to ensure a comfortable fit. Also, chlorine resistance, to prolong garment life in pool environments. And last but not least, UV protection, to safeguard wearers from harmful sun exposure.

Additionally, fabric technology advancements have greatly enhanced swimwear’s performance. For instance, introducing materials that retain color and shape despite repeated use and exposure to harsh conditions. This focus on high-performance fabrics is equally significant in activewear manufacturing. It is evident the demand for materials that can handle rigorous physical activity while maintaining comfort and aesthetic appeal is high.

The transition between the two industries underscores a shared emphasis on innovation, with fabric technologies playing a pivotal role in redefining what consumers expect from their sportswear and swimwear in terms of functionality and durability.

Fabric Selection for Activewear

In activewear manufacturing, the choice of fabric is influenced by the need to accommodate a range of physical activities, from yoga to high-intensity training. Performance fabrics such as polyester, known for its moisture-wicking properties, nylon for its durability and flexibility, and spandex for its unparalleled stretch, are commonly used.

Each fabric brings specific advantages to the table; for example, moisture-wicking materials keep the wearer dry and comfortable during intense workouts, while compression fabrics offer support and can improve blood circulation. The use of advanced textiles that combine these features allows manufacturers to create activewear that meets the varied needs of consumers, optimizing performance and enhancing the overall athletic experience.

This strategic fabric selection is crucial in developing activewear that not only performs under pressure but also aligns with the growing consumer demand for functional, fashionable, and sustainable options.

What are the Best Fabrics a Brand can Choose?

Selecting the right fabrics is a crucial decision for brands within the swimwear and activewear sectors, demanding a balance between technical performance, aesthetic appeal, and sustainability. Ideally, brands should gravitate towards materials that offer durability, flexibility, and moisture management to ensure that garments can withstand rigorous use while keeping the wearer comfortable.

Here are 5 of the best fabrics to choose:

- Recycled Polyester: Offers sustainability by repurposing plastic waste into durable, performance-oriented fabric suitable for both swimwear and activewear, featuring quick-drying and moisture-wicking properties.

- Nylon: Renowned for its strength and elasticity, nylon provides excellent fit and resistance to wear and tear, making it a top choice for high-impact swimwear and activewear.

- Organic Cotton: Ideal for low-impact activities, offering breathability, softness, and eco-friendly benefits, thanks to its chemical-free cultivation process.

- Bamboo: Recognized for its natural softness, antibacterial properties, and moisture-wicking ability, bamboo fabric is a sustainable option that provides comfort for everyday activewear.

- Spandex (Lycra/Elastane): Essential for ensuring stretch and flexibility, spandex enhances the fit and movement of garments, crucial for both swimwear and activewear that demands body-hugging properties.

Why Choose These Fabrics?

The selection of these fabrics represents a harmonious blend of performance, sustainability, and comfort, addressing the core needs of swimwear and activewear. For example, recycled polyester stands out for its eco-friendly profile, turning plastic waste into high-quality fabric that reduces landfill and conserves petroleum resources. Its durability and quick-drying characteristics make it a preferred choice for swimwear.

Nylon’s exceptional strength and elasticity ensure that garments retain their shape and offer superior resistance to abrasion, crucial for active and water-based activities. Organic cotton introduces a soft, breathable option for less intensive workouts, prioritizing environmental sustainability without chemical pesticides or fertilizers. Bamboo fabric is chosen for its natural antibacterial properties and moisture-wicking capability, offering a comfortable, odor-resistant option for activewear.

Lastly, spandex is indispensable for providing the necessary stretch and flexibility, ensuring that garments fit snugly and support a wide range of movements. Together, these fabrics embody the ideal qualities sought after in modern swimwear and activewear: performance, eco-consciousness, and wearer comfort.

Best Countries for Swimwear and Activewear Manufacturing

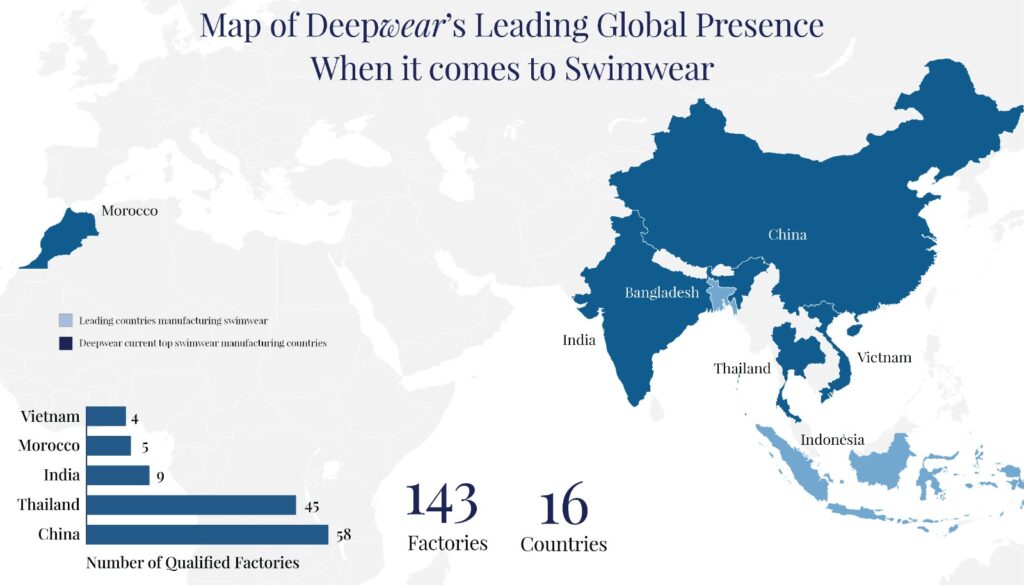

Identifying the best countries for manufacturing swimwear and activewear involves considering factors such as fabric quality, production expertise, sustainability practices, and cost-effectiveness. The following countries stand out for their contributions to the swimwear and activewear sectors:

- China: Dominates global manufacturing with its extensive infrastructure and technological capabilities. China offers a vast selection of fabrics, including advanced and sustainable options, making it a versatile choice for producing high-quality swimwear and activewear.

- Vietnam: Has rapidly become a key player in the textile industry, known for its skilled workforce and commitment to quality. Vietnam’s growing focus on sustainable practices makes it an attractive option for eco-conscious brands.

- Bangladesh: Offers competitive manufacturing costs while improving its sustainability and ethical labor practices. It’s becoming a go-to for brands looking for affordability without sacrificing quality, especially in activewear.

- Portugal: Stands out in Europe for its high-quality textile production, innovative fabric technologies, and sustainable manufacturing processes. Portugal is especially renowned for its premium swimwear and activewear lines.

- Italy: Known for luxury fashion manufacturing, Italy excels in producing high-end swimwear and activewear. It offers superior craftsmanship and innovative, sustainable fabrics, catering to premium market segments.

Pros and Cons of Each Country for Swimwear and Activewear Manufacturing

Choosing the right country for manufacturing swimwear and activewear is a critical decision for brands, influenced by factors such as cost, quality, sustainability, and speed to market. The landscape of global manufacturing presents a variety of options, each with its unique strengths and challenges. Here, we explore the pros and cons of key manufacturing countries, providing insights to help brands navigate these complex considerations.

China

- Pros: Extensive manufacturing infrastructure, vast range of fabrics, competitive pricing, and rapid production capabilities. Strong in both bulk production and innovative fabric technologies.

- Cons: Concerns over labor practices, environmental regulations, and the potential for higher import tariffs in some markets.

Vietnam

- Pros: Increasing investment in sustainable practices, skilled labor force at competitive costs, and favorable trade agreements with many countries. Strong growth in textile quality and innovation.

- Cons: Limited raw material production, leading to import dependency, and infrastructure still developing in comparison to more established manufacturing hubs.

Bangladesh

- Pros: Highly cost-effective labor, improving sustainable and ethical manufacturing practices, and substantial capacity for large volume orders.

- Cons: Political instability and infrastructure challenges can affect production timelines and quality consistency.

Portugal

- Pros: High-quality production with a focus on sustainable and innovative fabrics. Strong in niche and premium markets, with good labor practices.

- Cons: Higher manufacturing costs compared to Asian countries and limited capacity for extremely high-volume production.

Italy

- Pros: Renowned for luxury and high-end fashion manufacturing, superior craftsmanship, and innovative sustainable fabrics. Strong design and brand prestige.

- Cons: Premium pricing and the cost might be prohibitive for startups or brands targeting mid-market segments.

Challenges and Opportunities

The journey of sourcing and utilizing quality fabrics for swimwear and activewear presents both challenges and opportunities. One of the primary hurdles is achieving the right balance between performance, sustainability, and cost. The push towards eco-friendly materials, while necessary, often comes with higher price tags and sourcing complexities.

Additionally, ensuring fabric quality and consistency across production runs can be challenging, impacting the final product’s performance and durability. However, these challenges also open doors to innovation within the fabric manufacturing sector. There is a growing opportunity to develop new materials that are both environmentally sustainable and capable of meeting the high-performance standards required by the activewear and swimwear industries.

Advances in textile technology, such as the creation of biodegradable fabrics and improvement in recycling processes, demonstrate the industry’s potential for significant growth and positive change, aligning with the global shift towards more sustainable fashion practices.

Sustainability in Fabric Manufacturing

Sustainability in fabric manufacturing has become a central focus for the swimwear and activewear industries, driven by an increased awareness of environmental impacts and consumer demand for eco-friendly products. Manufacturers are exploring a variety of eco-friendly fabric options, such as recycled polyester made from plastic bottles and regenerated nylon, to reduce waste and conserve resources.

Organic cotton and bamboo fibers are also gaining popularity for their lower environmental footprint compared to conventional materials. Several brands are leading the way in sustainable practices, showcasing how innovation in fabric development can align with ecological values.

For instance, some have introduced swimwear made entirely from recycled fishing nets and other ocean waste, turning pollution into functional and stylish garments. These case studies exemplify the industry’s potential to contribute positively to the environment while meeting consumer expectations for quality and sustainability.

Conclusion and the Role of Deepwear within the Swimwear and Activewear Manufacturing Sector

As the swimwear and activewear sectors continue to evolve, the emphasis on fabric technology and sustainability becomes increasingly critical. The journey towards creating garments that not only meet the high standards of functionality and style but also adhere to principles of environmental responsibility is complex.

This is where Deepwear steps in, bridging the gap between innovation and sustainability. By offering insights and expertise in fabric selection, Deepwear empowers brands to navigate the myriad choices in materials, focusing on those that are both high-performing and eco-friendly. Deepwear’s role in the industry goes beyond consultation; it is about partnership, guiding brands towards practices that not only benefit the consumer but also the planet.

As we look to the future, Deepwear’s commitment to sustainability and its deep understanding of fabric technologies will continue to play a pivotal role in shaping the direction of swimwear and activewear manufacturing. Their expertise is instrumental in leading the industry towards a more sustainable and innovative future, demonstrating that high-quality, environmentally responsible garments are not only possible but are the new standard.

Did You Find This Article Helpful?

If you found this article helpful please share it with your friends, family and colleagues. In the meantime you can learn more about us and what we do on Deepwear flagship website or on our official Facebook page. Alternatively, you are more than welcome to request a meeting with a member of our team using the form below.