Learn how Deepwear guides brands through garment sampling—from proto to pre-production, fit, and marketing samples—ensuring quality, consistency, and reduced production risks.

Sampling is a critical stage in transforming design ideas into finished products. It allows brands to test fit, materials, finishes, and overall quality before committing to bulk production, helping prevent costly errors and ensuring designs meet expectations.

In this blog, we cover the key sampling types that can help brands refine and validate their products:

- Development (Proto) Samples – first physical translation of sketches or tech packs.

- Fit & Size Set Samples – ensure comfort, shape, and sizing consistency across collections.

- Salesman & Pre-Production Samples – prepare products for buyers and final approval.

- Photo & Wash Samples – check appearance, textures, and special treatments.

- Shipping / Gold Seal & Counter Samples – verify bulk production and maintain repeat-order consistency.

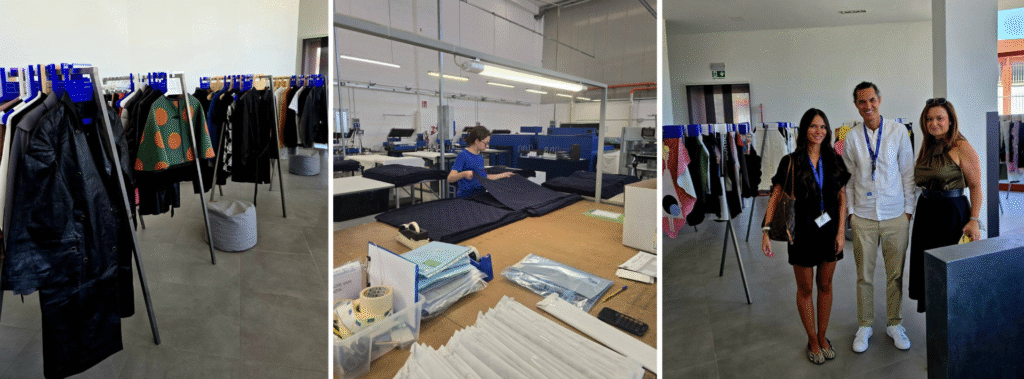

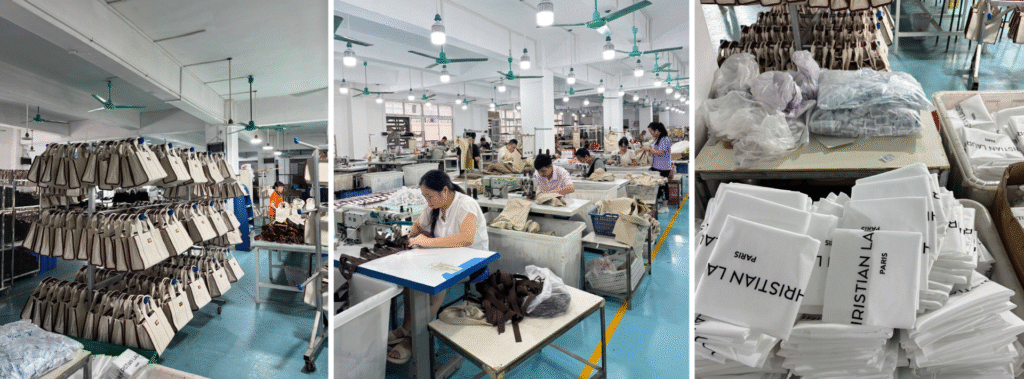

With on-the-ground teams across multiple production countries, Deepwear can support brands through sourcing, global garment manufacturing partner networks, design, and tech packs—helping ensure each sample reflects the brand’s vision before scaling up production.

What Are the Key Sampling Types in Garment Production?

Each type of sample serves a specific purpose, helping brands validate design, fit, materials, and production quality before committing to bulk manufacturing.

From the first translation of a sketch to samples used for marketing or repeat orders, these stages provide risk management in fashion, quality assurance, and design refinement opportunities. At Deepwear, our global team can guide brands through every sampling stage, offering hands-on support in sourcing, manufacturing, design, and tech packs to ensure each product aligns with the brand’s vision.

Below, we explore the main types of samples brands typically develop and how Deepwear can support each stage.

1. Development (Proto) Sample

The Development (Proto) Sample is the first tangible translation of a sketch or tech pack into a real product. Its purpose is to validate style, measurements, and overall design feasibility before moving further in production.

Deepwear can support this stage by facilitating communication between the brand and factory, reviewing tech packs, and evaluating design feasibility across multiple production countries. This step can help prevent costly errors and misinterpretations early in the process.

Learn more about how a detailed tech pack can guide proto samples: Why Tech Packs Are Essential in the Fashion Industry

2. Fit Sample

A Fit Sample is made to test how a garment fits on the human body. It can help confirm comfort, shape, and grading accuracy across sizes.

Deepwear’s team can provide feedback based on international sizing standards, helping brands anticipate market expectations and avoid inconsistencies when scaling production.

3. Size Set Sample

Size Set Samples are produced for all sizes in a range to confirm consistency and accuracy. This step can reduce bulk production errors and ensures the final sizing works across the entire collection.

Deepwear can oversee outputs across multiple factories, comparing workmanship and measurements to provide an additional layer of verification and reduce risks when production is split across sites.

For insights on aligning sampling with production efficiency, see: Factors You Should Consider for Efficient Production

4. Salesman Sample (SMS)

A Salesman Sample (SMS) is created for buyer presentations, exhibitions, and marketing purposes. It can demonstrate the collection’s quality and style before production begins.

Deepwear can help brands prepare samples that accurately reflect production quality, allowing them to present collections confidently and avoid misrepresentation.

5. Pre-Production (PP) Sample

The Pre-Production Sample represents the final approved product before bulk manufacturing. It includes fabrics, trims, and detailed workmanship.

Deepwear can assist by reviewing these samples and identifying potential issues, helping brands reduce risks of defects or delays in bulk production. Skipping this stage can lead to costly corrections and misaligned expectations.

6. Photo Sample

Photo Samples are prepared for catalogs, e-commerce, and marketing campaigns. They can help brands see how garments look on camera, including color, texture, and finishing details.

Deepwear can support brands in aligning these samples with production standards, ensuring that what is photographed closely represents the final product delivered to buyers or consumers.

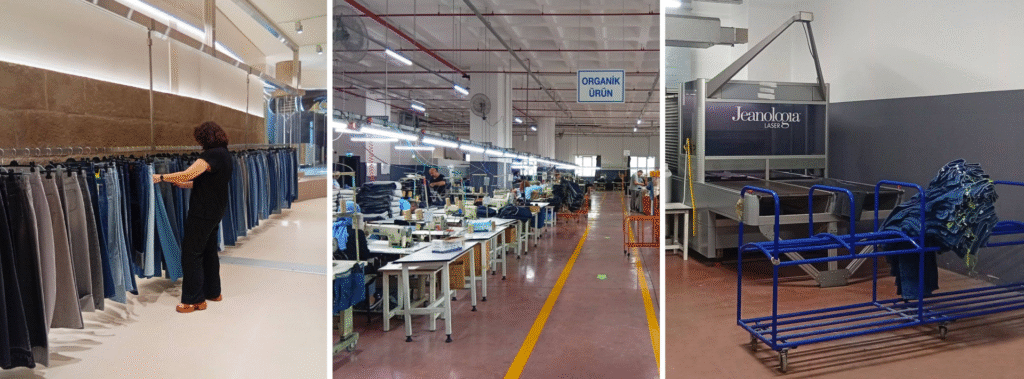

7. Wash Sample

Wash Samples are primarily used for denim or garments requiring special treatments, testing effects like stone wash, acid wash, or enzyme wash.

Deepwear can coordinate these trials across factories, helping brands achieve consistent results when scaling production.

8. Shipping Sample / Gold Seal Sample

A Shipping Sample or Gold Seal Sample is taken from bulk production to confirm it matches the approved Pre-Production Sample.

Deepwear can audit these samples on-site, helping brands verify factory compliance and quality consistency before products are shipped.

9. Counter Sample

A Counter Sample is a reference sent by the brand for repeat orders, ensuring that new batches maintain the same fit, quality, and design details as previous production runs.

Deepwear can monitor counter samples across factories and seasons, giving brands confidence that repeat orders remain consistent with previous collections.

What Is the Garment Sampling Process in Fashion Production?

Across every stage, the garment sampling process — from proto, fit, PP, SMS, photo, wash, to gold seal samples — validates quality, reduces risks, and optimizes costs. Each type of sample ensures the final product meets design, fit, and production expectations while protecting brand investment.

How Deepwear guides the entire process:

- Our team can oversee each stage with hands-on support in clothing prototyping and apparel product development

- We can provide expert coordination across a global garment manufacturing partner network

- We offer sustainable sampling solutions to minimize waste and improve efficiency

- At Deepwear, our team works to guide samples so they reflect brand vision, meet production standards, and satisfy buyer expectations as closely as possible.

How Sampling Supports Brand Confidence

Every sample stage can protect a brand’s investment and reputation by highlighting potential issues before mass production. Beyond quality checks, samples give designers and brands the insight needed to refine details, confirm fit, and validate finishes—helping avoid costly revisions later.

At Deepwear, our global presence and hands-on team allow brands to leverage:

- Strategic Sourcing: Access to materials and components that fit design and production requirements.

- Manufacturing Oversight: Coordination across factories to ensure samples translate accurately from concept to production.

- Design and Tech Pack Support: Guidance to turn ideas into actionable production plans, minimizing errors.

- Quality Control at Every Stage: On-site inspections, audits, and verification for consistency.

- Advisory Services: Expert advice on production strategy, order quantities, and cross-factory alignment.

By combining on-the-ground expertise with international insights, Deepwear can help brands validate each sample, reduce risks, and safeguard the final product—from concept through delivery.

Ready to reduce sampling risks and scale your production with confidence? Book a strategy call with Deepwear’s fashion consultants or explore our full garment development services today.