Garment Industry in India

India has a long and rich history of garment production. India has been known for its exquisite textiles for centuries, and this craftsmanship has been passed down from generation to generation.

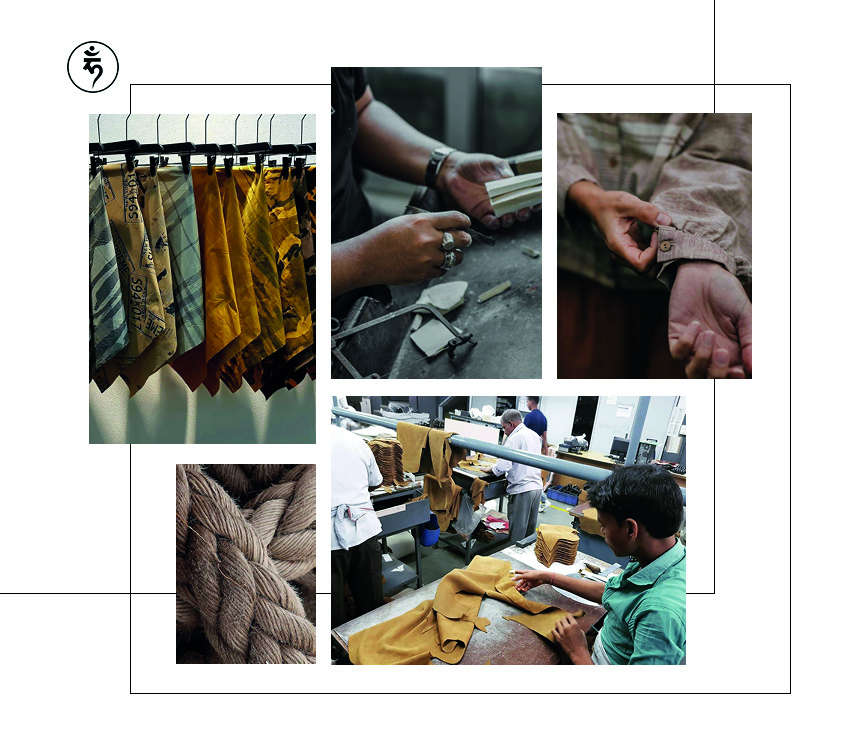

Many of the world’s most coveted fabrics – such as silk, cotton, and linen – are produced in India. The country’s vast array of climate zones also allows for a diverse range of crops to be grown, providing an abundant supply of raw materials for the textile industry.

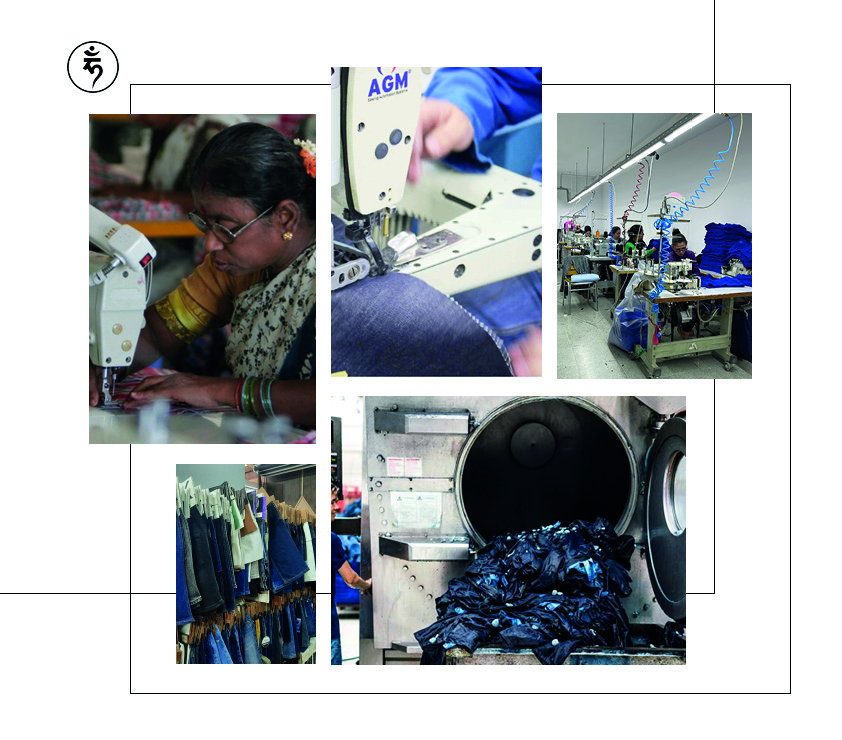

Garment production in India has also undergone a dramatic transformation. Thanks to advances in technology, Indian factories are now able to produce garments at a fraction of the cost of their Western counterparts. As a result, India has become one of the world’s leading clothing producers.

Today, you can find Indian-made garments in retail stores all over the globe. And with India’s extensive population of skilled workers, there is no doubt that this trend will continue for many years to come.

Production and Garment Factory Conditions

As the world’s second country with the largest population, India is home to a burgeoning garment industry that is providing employment to millions of people.

Despite its success, there are some concerns that need to be addressed in order to ensure sustainable growth in this sector. The production of garments in Indian factories requires thorough monitoring systems of quality compliance and timing. Factories in India also must adhere to a number of quality standards set by both the government and international buyers.

Quality compliance refers to the following aspects:

- Use of proper raw materials,

- Compliance with safety standards,

- Conformance to design specifications,

- Observance of timely delivery schedules.

The lack of transparency in the supply chain makes it challenging to get an accurate picture of the overall conditions at garment factories in India. This makes it hard for brands and retailers to make informed decisions on ethical sourcing. This can also lead to manufacturing defects.

Therefore, it is crucial to abide by these standards and have a good quality control (QC) system in place.

Nevertheless, with excellent production management and quality control, garments produced in India have some advantages over other countries. There are plenty of skilled tailors and seamstresses who can create intricate garments. It is also important to note that all clothing is produced in different ways, and you must find a reliable supplier who can make garments of the level of quality that you require. To discuss in detail Indian garments manufacturing, sourcing, buying, or designing, contact us.

Trends in the Fashion and Textile Industry

The textile industry in India has undergone several changes over time. And there have been many trends that have greatly influenced this sector, including the two major ones: handmade works and industrial manufacturing.

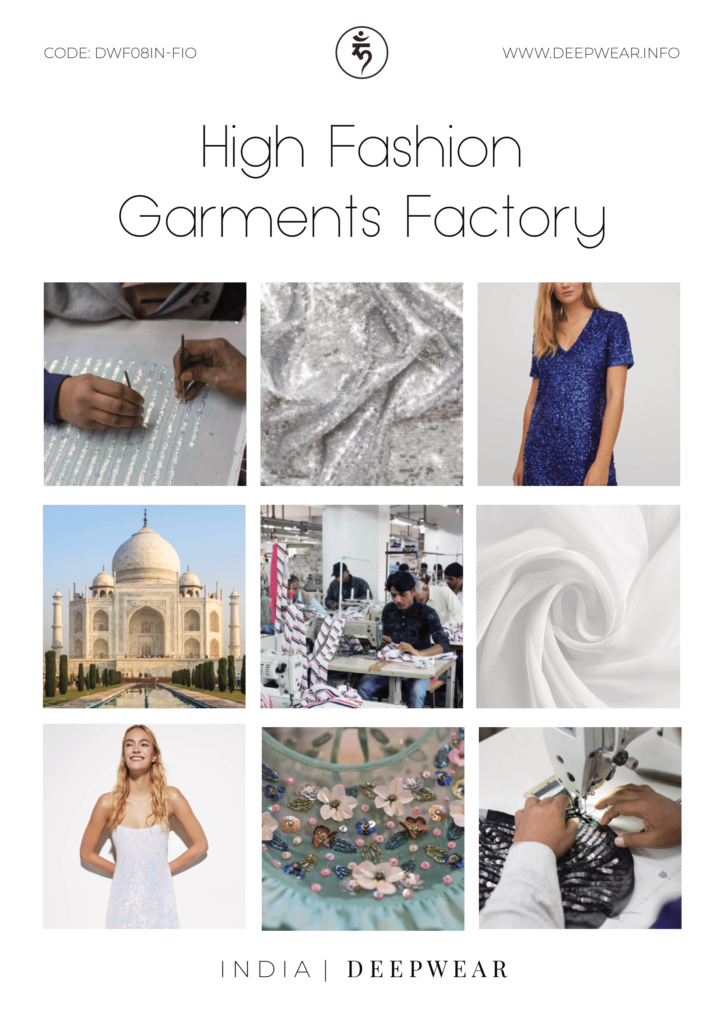

The handmade arts in India continue to grow in popularity, with many artists using traditional methods and materials to create their work. For example, India is known for creating high-quality embellished and beaded garments for high-end fashion brands. These garments are usually made by artisans who use a variety of techniques to create sophisticated designs.

And the beads used in these garments are typically made from glass or metal, and they are often strung onto the fabric using thread or wire. The finished product is both beautiful and durable, and it can take many months to complete a single garment.

In addition to their aesthetic appeal, embellished and beaded garments also have a practical purpose. They can help to protect the wearer from the sun and the cold, and they can also provide a little extra padding in case of a fall. Therefore, these garments are highly prized by both Indian women and tourists alike.

Some of the most popular trendsetters in this field also include using 100% organic fabrics. In fact, if you’re looking for organic cotton, there’s a good chance it came from India.

India is the largest single producer of organic cotton in the world.

But, how did India become such a major player in the organic cotton market?

Part of it has to do with geography. India is located in an ideal climate for growing cotton, and it has years of experience in producing crops.

The vast majority of India’s organic cotton is grown in the state of Maharashtra, which is home to over half of the country’s certified organic cotton farms.

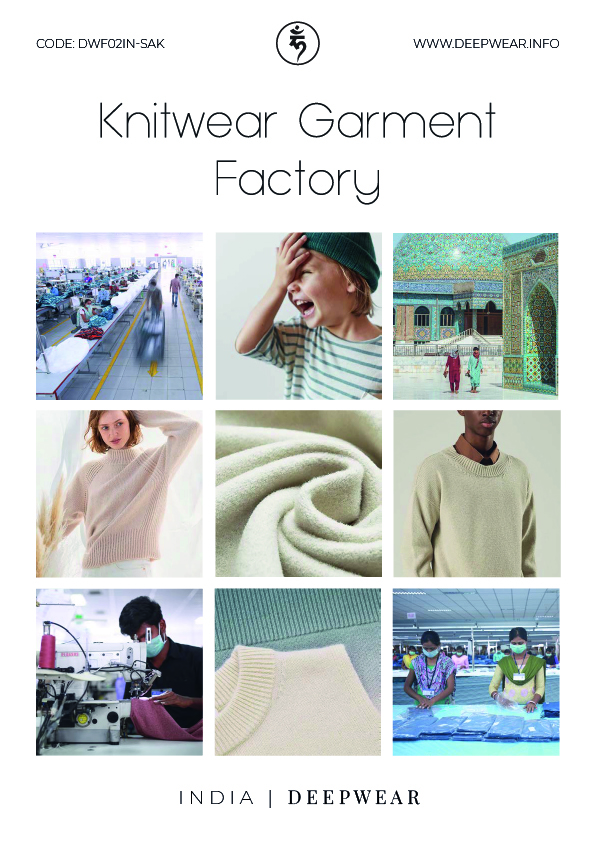

Along with embellishments, artists in India are also into local crafts as opposed to European-influenced designs and styles. This includes various types of textiles like woven and knitted fabrics.

The second trend in the textile industry in India is industrial manufacturing. It has shown an ever-increasing rate with production capacity reaching up to around 13% of total global output by 2020.

And because of these technological advances, there were better production and quality control, as well as improved efficiency and accuracy. These machines make it possible for factories to elevate their operations without expanding their workforce.

This has been a key factor in driving down costs, which allows for cheaper production and products being sold at lower prices. And processes like automatic printing, digital printing, handmade printing techniques, and even the use of dye are now easily done in garment production because of the advancements in machinery.

As a result, garment factories in India are becoming more flexible as they adapt to changing market needs and requirements.

But keep in mind that not all manufacturers in India have access to these technological innovations, and thus, being extra careful in choosing a trustworthy manufacturer is a must. It is also essential to know their level of expertise on the type of product you are looking for.

And to help you out choose the perfect garment manufacturers in India, Deepwear is here to assist you! At Deepwear, we specialize in working with suppliers from around the world to create and deliver high-quality and fashionable consumer products. We are a strategic partner for companies looking to expand their sourcing options and source products closer to their final destination.

Moreover, Deepwear is the foremost fashion sourcing agency in India, offering a one-stop solution for global apparel brands to source garments as well as accessories from the best factories in India.

Different Types of Textile Industries

Aside from woven and knitted fabrics, there are different types of fabric in India. But generally, India consists of four main textile types.

Cotton Textile Industry

The cotton textile industry in India is the largest and oldest producer of cotton in the world. It is also considered to have the largest cotton cultivation area globally, with an estimated production of about 4.4 million bales in 2007-08.

For instance, cotton is grown in over 5000 square kilometers in a state in India called Andhra Pradesh. Half of these are irrigated. Apart from Andhra, cotton is mainly distributed to several cities such as Maharashtra, Gujarat, Tamil Nadu, Uttar Pradesh, West Bengal, Madhya Pradesh, Karnataka, Andhra Pradesh, Kerala, Haryana, Punjab, and Delhi.

The Indian cotton textile industry has developed rapidly over the past few decades because of the increasing global market demand. However, over time many big businesses have left the industry due to competition from imports and strong anti-dumping measures applied by the government.

Woolen Textile Industry

India has the seventh-largest wool-producing capacity and the third-largest sheep population in the world. But because of the shortage of domestic production, there has been a heavy reliance on importing wool from Australia and New Zealand.

And top production of woolen takes place in cities like Punjab, Haryana, Rajasthan, Uttar Pradesh, Maharashtra, and Gujarat.

Silk Textile Industry

India is the second-largest producer of silk in the world. The sector comprises 14,227 commercial seed rearers and more than 50 weaving clusters present in the country.

Silk in India is produced in Karnataka, Andhra Pradesh, and Tamil Nadu, creating all four types of commercially available silk – Mulberry, Tasar, Eri, and Muga. The textile industry in India also employs millions of people, particularly in rural areas, and is worth 248.56 million U.S. dollars.

Jute Textile Industry

The jute textile industry in India is one of the most important industries in the country. It is second to the cotton industry in terms of production. It employs 0.37 million workers and contributes significantly to the economy.

However, the industry has been facing challenges caused by the competition hike from synthetic fibers and other factors.

For example, the industry is mainly based on exports, and so any negative impact on exports has a significant impact on employment. Not only that, but the advent of synthetic fibers also affected the fabric’s production.

Many leading manufacturers exist in India’s eastern regions, including Bihar, Assam, and West Bengal, producing four-fifths of all jute in the country.

Major Indian Garment Manufacturers’ Hubs

India has ten primary clothing production hubs. These specialize in manufacturing all sorts of garments. Tirupur, also known as India’s “T-shirt Town,” is located in the southern state of Tamil Nadu, and it has over 1500 units of manufacturing facilities producing the finest knitwear garments.

On the other hand, places like Noida, Gurgaon, and Ludhiana have also become part of the garment factory in India, focusing on small and large production of ready-made children’s and women’s wear.

In addition to this, there are many other small towns that also make an extensive number of garments for different sizes and age groups. The major cities in India like Mumbai, New Delhi, and Bangalore have more than one million people working in the textile industry alone!

Sustainable Garment Manufacturing in India

Sustainability is more than a buzzword. It is a practice that has slowly gained momentum over the years and is now firmly placed in the mainstream. The idea of sustainability encompasses many aspects, including the business’s environmental, social, and financial factors. It also includes the choice of raw materials and manufacturing processes used to make products.

And therefore, because of the changing consumer preferences, increasing environmental responsibility, and rising costs, garment manufacturers in India adapted their processes and practices to utilize resources better and reduce waste generation.

Some companies have chosen to use organic fabrics, while others have opted for natural dyes or recycled materials in their production processes. Additionally, some brands have implemented strict guidelines when it comes to their suppliers and labor conditions in their factories.

In particular, certifications provided by companies like Business Social Compliance Initiative (BSCI) and Supplier Ethical Data Exchange (SEDEX) are recognized by several major retailers as proof of a company’s commitment towards sustainability practices.

But even if these certifications have been granted to a factory it doesn’t guarantee their validity and integrity. Therefore it is necessary for brands to look beyond certification bodies and develop their own sustainability criteria for suppliers.

And to check their credibility, you will need an exclusive audit or visit of manufacturing sites. You can also do this with the support of an independent team like Deepwear.

And the Deepwear team will be in-charge and present during all the production to make sure the factory is not subcontracting and respect sustainable manufacturing. Sustainability is the way

And another good news is that Deepwear aims to ensure that textile production in India is genuine and is committed to economically viable practices. We have a large network of sustainable and ethical garment factories in India that intend to deliver the finest garments to customers.

Furthermore, At Deepwear, we help our clients track their supply chain. Through our lab testing of products’ material, we ensure that our client’s products are free of harmful chemicals and skin-friendly and confirm you the real composition of the fabric.This is because some factories often lack transparency in their production processes. Click here to know more about the difference Deepwear makes, and let us be your sustainable partner!

Why Choose Deepwear As Your Sourcing Company For Your Garments?

With over 25 years of experience, Deepwear became a sourcing and production specialist to meet the changing dynamics of requirements of local and international buyers.

Our 100% commitment to our clients and unrivaled textile and apparel sourcing capabilities give us the possibility to deliver and protect the brand’s reputation.

We also have the knowledge and connections to help you navigate the often-complex process of manufacturing garments in India. And a major advantage of choosing Deepwear is having on-the-ground professionals based in two Deepwear offices in India located in the middle of the biggest garment manufacturing hub, Mumbai and New Delhi / Noida.

This means we can easily have access to the latest trends and developments in the Indian market. We are also hands-on in managing your productions and quality control. Get in touch.

And without collaborating with a supplier and an independent team like Deepwear who are constantly present on the ground in India, you will face significant delays, cost overruns and product damages. You will also find yourself caught up without any recourse if something goes wrong.

So, if you’re considering manufacturing garments in India, Deepwear can support and protect you from these risks by providing an accountable and reliable supplier for your brand. To learn more about how we can help, Stay Connected