Learn how fashion brands manage garment costing with Deepwear—from fabrics and MOQ to trims and logistics—ensuring transparency, accuracy, and supplier trust.

For fashion brands, the garment costing process is one of the most important steps in turning a concept into a market-ready collection. But breaking down prices, negotiating with factories, and securing fair terms is rarely straightforward—especially for small or emerging labels.

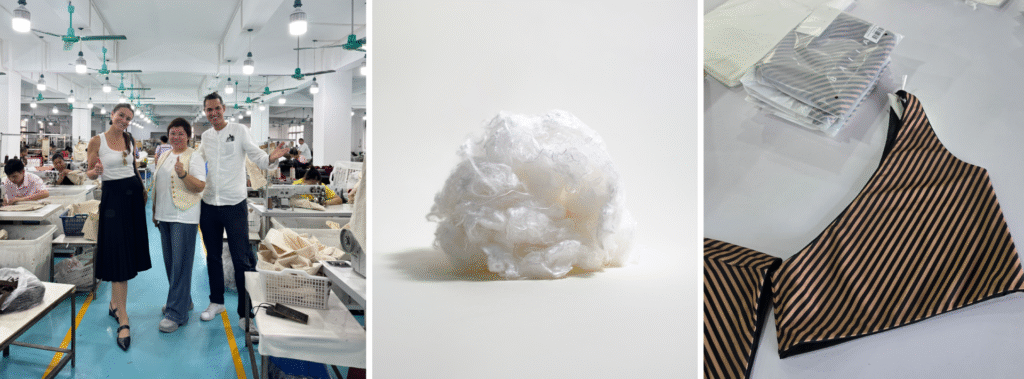

That’s where Deepwear garment consulting comes in. We act as your partner and advocate, ensuring suppliers take your brand seriously, costs are transparent, and every detail is accounted for. Our experience across 17 countries allows us to guide clients confidently through the costing process without compromising quality or profitability.

This guide will walk you through:

- How garment costing is typically broken down with factories

- Which factors influence final garment prices most

- Ways Deepwear can add value for small and emerging brands

- How transparency and collaboration create smoother supplier relationships

Breaking Down the Garment Costing Process

Costing in fashion production is rarely a simple figure. What looks like a single “per-piece price” often has layers—factory quotes, packaging, add-ons, and order volumes all influence the final outcome. At Deepwear, we guide brands through this process step by step, so every element can be considered before decisions are made.

Receiving Factory Prices

Deepwear typically receives garment costing directly from the factory. Most prices are quoted EXW (Ex-Works), though if a client requests FOB (Free on Board), we can ask for that option as well. The initial costing usually reflects the finished product, but it is often just the beginning of the discussion.

Because factories tend to prioritize larger orders, emerging brands may be overlooked. Deepwear can bridge this gap by representing your interests, showing suppliers that you have professional backing and long-term potential.

Special Add-ons & Packaging

Custom packaging, embroidery, or print moulds are usually costed separately, and without guidance, brands may underestimate these additional expenses. . To make budgeting clearer, Deepwear typically requests three MOQ (Minimum Order Quantity) costings from suppliers. Having three scenarios—such as low, medium, and high order volumes—helps you see how unit costs change as quantities increase. This approach strikes the right balance: enough options to compare effectively without overcomplicating the decision-making process or overwhelming suppliers.

Key Factors in Garment Costing — and How Deepwear Adds Value

The garment costing process depends on more than just fabric or labor—it can be shaped by timing, supplier capacity, and how a brand is positioned in the eyes of a factory. Deepwear can support brands in understanding these factors and add value by offering guidance, negotiation, and credibility when working with suppliers.

- Minimum Order Quantities (MOQ) MOQ often has the biggest impact on garment costing. Factories usually prefer larger, stable orders, while smaller runs can be priced higher. Deepwear can help balance this by securing practical MOQ options and communicating the long-term value of working with your brand. Even a modest first order can be positioned as part of a longer growth plan.

- Pricing Structures & Cost Planning Many new brands underestimate how to structure their prices—whether to build in buffer margins, how to balance wholesale versus retail, or where to cut costs without harming quality. Deepwear advises clients on how to prepare a clear pricing structure before negotiations begin, so you can approach factories with confidence and clarity.

- Negotiation Strategies with Factories Negotiating fairly with suppliers is both an art and a science. Deepwear guides brands on which strategies work best depending on the order size, production country, and supplier relationship. This ensures you don’t just accept the first quote but engage in a dialogue that creates value for both sides.

- Fabric & Material Selection Fabric choices influence both quality and price. With sourcing options available across global markets, costs can fluctuate depending on availability and demand. Deepwear can support clients by sourcing competitively and balancing material selection with quality, sustainability, and budget.

- Workmanship & Labor Intricate garments, technical sewing, or finishing details often increase labor costs. Deepwear can help by discussing with factories how workmanship is priced, giving brands a clearer view of where costs may rise. This can guide decisions on whether to simplify a design or highlight certain features as premium elements.

Discover our Design Consultation & Production Support to make sure every detail fits your goals.

- Lead Times & Production Cycles Short deadlines and peak production seasons can add cost pressures. With oversight from Deepwear, brands may be able to plan production around factory capacity or choose more flexible timelines, which can help secure better rates and smoother production flow.

- Shipping & Logistics Logistics can play a large role in final garment costs, from freight charges to customs duties and Incoterms (EXW, FOB, CIF). Deepwear can highlight these factors early in the process, so clients are less likely to face unexpected costs at a later stage.

- Supplier Relationships & Long-Term Partnerships Factories often give priority to brands they see as reliable partners. Deepwear can help demonstrate your seriousness and growth potential, opening doors that smaller labels might not reach alone. Just as factories avoid operating at a loss, so do we—we aim to foster relationships where both brands and suppliers benefit, which may create better opportunities over time.

Ensuring Transparency and Accuracy

Costing is not just about numbers—it is also about clarity. Misunderstandings, vague quotes, or unexpected charges can appear along the way. Deepwear can support brands by creating space for open communication and shared analysis, so costs are reviewed carefully before decisions are made.

- Direct Client–Supplier Interaction Deepwear often arranges video meetings where clients can speak directly with suppliers. This can reduce miscommunication, build trust, and give brands a better understanding of how costs are presented. But we don’t stop there—we welcome and even encourage brands to visit production countries and factories in person. Seeing production firsthand gives you greater transparency and helps foster stronger, long-term

- Collaborative Cost Review Rather than simply accepting a factory quote, Deepwear can review the details with clients and suppliers together. This collaborative approach may lead to fairer discussions and a clearer view of where costs come from.

- Flexible Payment Options Deepwear offers flexibility in payment coordination. Clients may choose to pay suppliers directly or work through us, depending on what suits their needs best. Both options can support smoother transactions and better financial planning.

Frequently Asked Questions About Garment Costing

Costing in fashion production can raise a lot of questions, especially for brands preparing their first collections. Below are some of the most common queries we hear, along with how Deepwear can support at each stage.

What is included in garment costing?

Garment costing usually covers fabrics, trims, labor, and MOQ. Depending on the order, additional elements such as packaging, embroidery, or logistics may also play a role.

Why is MOQ important in garment costing?

MOQ can shape the unit price significantly. Larger orders often lower costs per piece, while smaller ones may be priced higher.

How can Deepwear help with garment costing?

Deepwear can request multiple MOQ options, coordinate with suppliers, and bring clarity to cost breakdowns. This support helps brands of all sizes make informed decisions with greater confidence.

How Do Fashion Brands Negotiate Garment Costs in 2025?

Fashion brands can negotiate garment costs by comparing multiple MOQ quotes, understanding fabric & material selection, and balancing speed with factory capacity. Deepwear supports this process with supplier credibility, transparent costing, and long-term sustainable garment sourcing strategies

Garment Costing is a Collaborative Journey

The garment costing process is about timing, relationships, and the choices a brand makes along the way. For emerging labels, it can feel overwhelming, while for more established brands, it still requires careful planning. With the right partner, the process becomes clearer and more manageable.

At Deepwear, we work alongside brands to help them approach factories with confidence, build lasting supplier relationships, and see costing as part of a bigger growth journey. By treating costing as a shared process rather than a fixed figure, brands can move forward with greater clarity and balance.

Ready to simplify garment costing and secure fair factory partnerships? Book a strategy call with Deepwear’s global consultants or explore our full garment sourcing solutions today.