Learn the most common woven fabric defects, their causes, and how Deepwear helps brands detect and prevent them through strategic sourcing and AQL inspection.

Achieving a flawless woven fabric is about more than aesthetics. It impacts production efficiency, sustainability goals, and brand reputation. Defects can multiply costs, delay schedules, and weaken consumer trust.This guide offers a deep dive into the world of woven fabric defects and how strategic sourcing can keep them under control. Here’s what you’ll learn:

- The most common types of woven fabric defects, with real-world examples

- The root causes of defects—from yarn spinning to final finishing

- How to inspect and detect defects early using best practices

- The business impact of poor fabric quality on production, timelines, and consumer trust

- How Deepwear helps brands prevent and resolve defects through proactive sourcing and AQL inspections

- What steps to take when you receive flawed fabric, and how to avoid repeat issues in future orders

With the right systems in place, you don’t just catch mistakes—you prevent them.

Why Woven Fabric Quality Matters

Woven textiles form the foundation of countless garments—from crisp shirts and structured dresses to premium denim and tailored trousers. When flaws go unnoticed until sewing begins, entire lots can be jeopardized. Issues like broken yarns, oily stains, or misaligned shrinkage can render lengths unusable or necessitate time-consuming patch jobs.

The ripple effect touches every stage of the value chain. Buyers may return shirts due to broken ends. Factories may face downtime replacing rolls. Designers may need to delay seasonal launches. And once consumers spot pilling or shade variations, brand loyalty suffers.

To prevent such outcomes, brands must understand defect sources and incorporate preventive checks early in sourcing and pre‑production.

What Causes Fabric Defects?

Fabric flaws seldom occur in a vacuum. These origins typically fall into four categories:

- Yarn quality issues — Neps, slubs, thick/thin places, and foreign fiber contaminants start here. Dusty environments or subpar spinning equipment increase the risk.

- Weaving process or machine glitches — Tension imbalances, worn heddles, faulty reeds, shuttle problems, and improper pick insertion create directional flaws such as bars, floats, broken ends, and weave misalignment.

- Finishing or handling mistakes — Over- or under‑singeing, oil contamination, uneven chemical baths, or mechanical damage during transport introduce stains, crease lines, skewing, and shrinkage problems.

- Inspection and quality‑control gaps — Inadequate lighting, rushed sampling, or lack of standardized grading systems allow minor flaws to pass through and surface further downstream.

This highlights why a fabric’s path—yarn, weaving, finishing, handling, and inspection—must be tightly monitored. Skipping checks at any stage increases the risk of defects appearing later, often when costs and impact escalate.

Common Types of Woven Fabric Defects

A defect classification helps brands and teams identify severity and take action. Here we use a four-category structure: yarn‑related, directional, mechanical/finishing, and appearance/surface defects.

A. Warp and Weft Directional Defects

These defects arise from inconsistencies along the fabric’s length (warp) or width (weft). They can compromise fabric structure and lead to functional failure or visible irregularities in the final garment.

Common examples include:

- Warp floats: Occur when warp yarns skip over multiple weft yarns, leaving the thread unanchored on the fabric face. This results in raised sections prone to snagging and abrasion.

- Weft bars: Horizontal lines or dense patches running across the width of fabric, often due to tension differences or inconsistent yarn count between batches.

- Warp curls: Lengthwise distortion that causes fabric edges to curl or ripple are commonly due to uneven take-up or beam tension.

- Streaks: Narrow lines running parallel to the warp, caused by yarn diameter inconsistencies or incorrect alignment in the loom.

- Broken ends/picks: Missing threads in the weave structure that form visible gaps or thin lines. If caught too late, these require reweaving or patching.

- Double picks/double ends: Two yarns inserted in place of one. This results in thick, raised lines that affect fabric texture and color consistency.

Common causes:

- Yarn tension mismatch between beams

- Faulty shuttle or rapier mechanisms

- Misaligned reed or drop wires

- Inconsistent warp loading

Inspection tips:

- Use angled light sources during roll inspection to highlight bar marks and floats.

- Check tension consistency during weaving because bars often appear at warp joins or yarn lot changes.

- Sample early cuts under magnification to spot broken ends or skips.

B. Yarn-Related Defects

Yarn quality plays a pivotal role in fabric consistency. Even with precise weaving equipment, defects rooted in yarn irregularities often appear after dyeing or finishing.

Common examples include:

- Neps: Small entanglements or knots of short fibers embedded in yarn, visible as tiny lumps on the fabric surface. They may resist dye, creating white specks after processing.

- Slubs: Deliberate or unintentional thick areas in yarn. While some slubbed fabrics are designed for a rustic look, random slubs result in uneven texture and dye pickup.

- Thick/thin places: Inconsistent yarn thickness along its length creates visible stripes or subtle density shifts across fabric.

- Foreign fibers: Non-native fibers (e.g., colored threads, hair, or packaging residue) mixed into yarns. These result in random discoloration or fiber pops after finishing.

Common causes:

- Poor carding or combing during spinning

- Contamination during transportation or storage

- Yarn sourced from mixed-quality suppliers

Are any of these ever intentional?

Yes. Slubs, for example, are intentionally added in fabrics like slub denim or certain types of linen and silk. But when unintentional, they indicate production defects and can compromise weave integrity.

Inspection tips:

- Visual inspection under white light reveals surface neps and fiber contamination.

- Run swatch dye tests to identify neps or foreign fibers that resist coloration.

- Set yarn specification standards with suppliers before production to avoid unapproved yarn types.

C. Mechanical and Process Defects

Mechanical flaws stem from machine wear, maintenance lapses, or incorrect setup. These are often unpredictable and must be caught during in-line inspection or finishing.

Common examples include:

- Float stitches: Threads skip over several yarns without proper interlacing. These are structurally weak and cause sagging or visible lines.

- Holes or cuts: Ranging from small punctures to large tears, they may be due to sharp components, handling errors, or loom issues.

- Oil stains: Grease or machine oil drops leave brown or yellow spots that often can’t be removed through washing.

- Shrinkage distortion: Uneven relaxation after weaving causes parts of the fabric to shrink more than others which results in skewed or misshapen pieces.

Common causes:

- Faulty heddles or needles

- Misaligned looms

- Oil leakage or overuse of machine lubricants

- Inadequate tension control during finishing

How they go unnoticed:

Many mechanical defects emerge only after heat or wet processes like dyeing, steaming, or calendaring. Float stitches may be undetectable on unfinished fabric, and shrinkage distortion becomes evident only after washing.

Inspection tips:

- Use the 4-point system to grade severity and frequency.

- Review maintenance logs from suppliers; frequent machine stoppages or re-threads are warning signs.

- Conduct pre-shipment fabric relaxation tests to measure potential skew or shrinkage.

D. Appearance and Surface Defects

These flaws may not alter fabric structure, but they significantly affect its visual appeal, uniformity, and alignment with brand aesthetics.

Common examples include:

- Shading: Variations in fabric tone, especially between rolls or within a piece. These inconsistencies are magnified in solid colors and light tones.

- Crease marks: Permanent fold lines that resist ironing, often from handling or storing damp fabric.

- Pilling: Loose fibers bunch together into tiny balls on the fabric surface after wear or washing. While common in synthetics, excessive pilling indicates fiber weakness or incomplete singeing.

- Misdraw/incorrect lifting: Weaving pattern error due to incorrect heddle sequencing or misthreading, producing a design that doesn’t match the intended pattern.

- Reed marks: Vertical lines caused by spacing errors in the reed are often from incorrect reed count or damaged reed wires.

Impact on visual quality:

Appearance flaws can be subtle at first glance but become glaring issues under studio lighting or consumer wear. A shirt with shading may look “off-color,” or pilling may lead to customer complaints after a few washes.

Inspection tips:

- Evaluate fabrics under controlled lighting, both warm and cool, to check for shading.

- Conduct rub tests for pilling resistance—especially for knits and poly blends.

- Cross-check woven patterns with CAD or tech packs to catch misdraws before cutting.

Managing Fabric Defects: Impact, Prevention, and Resolution

Woven fabric defects can’t be treated as isolated issues. They affect your margins, disrupt timelines, and risk consumer trust. Below, we break down the three key dimensions of managing these challenges: the impact on brands, how to prevent them through smarter sourcing, and what to do when defects appear.

How Fabric Defects Affect Brands

Even a minor flaw can result in major setbacks.

- Financial Losses

Defective fabric often leads to material waste, rework, or full order rejections. That translates to higher production costs, especially when defects are only caught post-cutting or during garment assembly. - Production Delays

Quality issues identified late in the process can derail your timeline. Lead times become compressed, adding pressure on teams and compromising finishing or packaging quality. - Retailer and Buyer Complaints

Distributors and retail buyers are quick to notice inconsistencies like shading, broken yarns, or pilling. If defects pass inspection and hit shelves, it damages the relationship, not just the product. - Consumer Returns and Brand Reputation

Inconsistent fabric appearance or performance leads to returns, negative reviews, and weakened brand trust. One small detail—like unexpected shrinkage or poor colorfastness—can have long-term effects on customer loyalty.

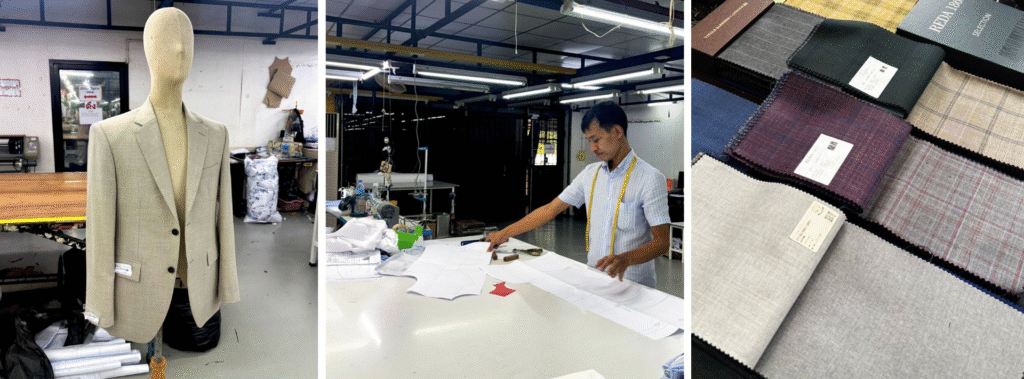

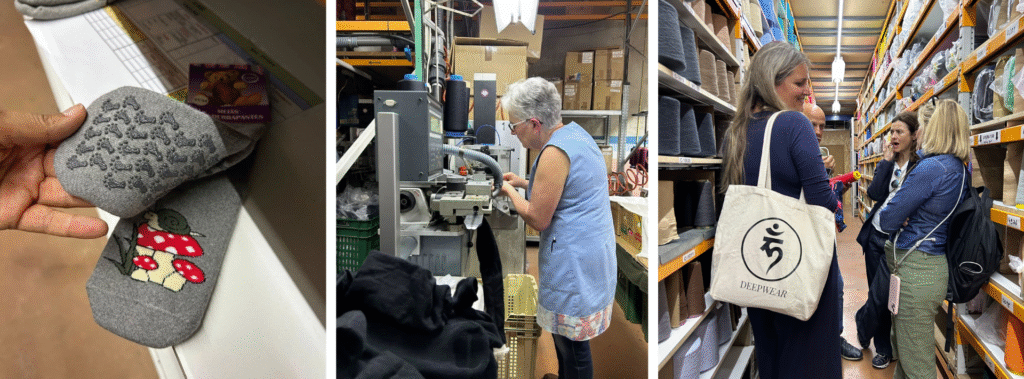

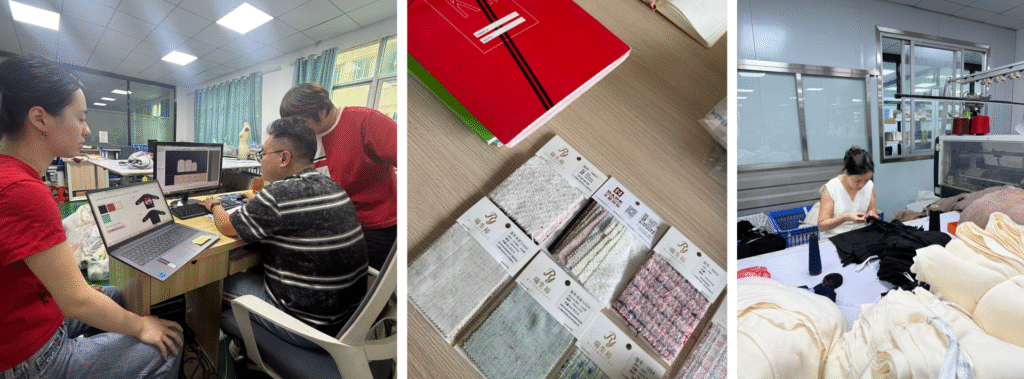

How Deepwear Helps Prevent and Manage Fabric Defects

We take a multi-layered approach to help brands minimize and resolve defects before they escalate.

- AQL-Based Inspections

Every production batch is reviewed using the AQL (Acceptable Quality Limit) standard. This involves sampling fabric rolls and evaluating defects by severity: minor, major, and critical. Critical flaws like holes or oil stains are never tolerated.

Read more in our blog: How AQL Standards Ensure Consistent Excellence in Bulk Production.

- Trusted, Vetted Manufacturers

We work only with mills and production houses that follow strict quality and environmental compliance standards. These long-term partnerships allow us to trace problems at the source and correct them quickly. - Pre-Production and In-Line Testing

Before bulk production starts, fabric is tested for pilling, shrinkage, dye consistency, and structural integrity. During weaving and finishing, inline checks help catch emerging issues like tension problems or surface distortions. - Transparent Quality Reporting

If a defect is found, brands receive detailed feedback with photos, severity rating, and recommended action. This allows you to make real-time decisions—whether it’s an approval with discount, a remanufacture, or a hold. - Proactive Problem Solving

For recurring issues like weft bars or shading, we consult with mills to adjust their process parameters. Our QC team actively tracks whether resolutions are sustained in future batches.

What to Do If You Spot Fabric Defects

Sometimes, defects may only appear after fabric has been delivered. Here’s how to respond:

- Document the Issue Clearly

Take high-quality images under natural or studio lighting. Note the type of defect, its location, and frequency. Refer to the original spec sheet or tech pack. - Use a Grading System

Apply either the 4-point system or your AQL tolerance thresholds to assess whether the issue is minor or major. This ensures a standard reference when discussing with your sourcing partner. - Decide on Next Steps

Depending on severity, you can request:- A discount or credit for minor, fixable issues

- A hold and replacement for major flaws

- A full rejection for critical structural or visual defects

- Work with Your Partner to Prevent Recurrence

Analyze the root cause together. If it’s a machine issue, tension misalignment, or poor yarn quality, ensure corrective steps are documented. A good sourcing partner won’t just fix the issue—they’ll prevent it from happening again.

Conclusion: Proactive Quality Management Starts with the Right Partner

Fabric defects are an unavoidable part of the textile world—but they don’t have to derail your production or put your brand at risk. The difference lies in how early they’re detected, how consistently they’re managed, and who you trust to oversee quality at every step.

Our approach goes beyond post-production checks. We believe in early-stage prevention—backed by technical expertise, transparent communication, and a vetted network of partners who take accountability for their output. Whether you’re scaling your collection or refining your materials for a premium drop, managing defects isn’t a side process; it’s core to protecting your product and your promise.

Need support with fabric inspections or sourcing partners who won’t cut corners?

Let’s work together to build quality into your production from the very first thread. Contact Deepwear to learn more or explore how our sourcing and inspection systems help leading brands maintain consistency at scale.