Explore the difference between natural and synthetic dyes, plus how Deepwear ensures fiber compatibility, colorfastness, and regulatory compliance.

Color brings fabric to life—but not all dyes are created equal. At Deepwear, we go beyond surface aesthetics, selecting dyes that balance fiber compatibility, colorfastness, sustainable color development, and compliance. Whether you’re creating an artisan capsule or scaling global production, choosing the right dye chemistry is critical to both quality and brand trust.

In this guide, we break down:

- The core differences between natural dyes and synthetic dyes

- Pros and cons of each from an environmental and production standpoint

- Key dye classes used across different fibers, with Deepwear’s sourcing insights

- Our QA process for ensuring dye durability and safety in real-world production

- What happens when dye fastness fails—and how we prevent it

- A preview of emerging dyeing technologies and Deepwear’s future-forward outlook

By the end, you’ll understand how Deepwear delivers high-performance color that holds up—visually, chemically, and reputationally.

Natural vs. Synthetic Dyes—What’s the Difference?

Natural dyes are derived from sources like leaves, bark, roots, fruits, and even insects such as cochineal. Historically significant and culturally rich, these dyes offer a muted, earthy aesthetic favored by artisanal brands, craft-focused labels, and eco-conscious consumers.

Pros:

- Biodegradable and low toxicity if untreated

- Culturally meaningful and great for storytelling

- Less impact on aquatic systems if discharged responsibly

Cons:

- Limited color palette

- Lower wash and light fastness

- Inconsistent results and harder to scale for large runs

Synthetic dyes, developed from coal tar and later petroleum-based chemicals, make up the majority of dyes used in fashion today. Their appeal lies in vibrant hues, colorfastness, and affordability—especially critical for global production lines.

Pros:

- Bright, reproducible colors across large batches

- Generally more wash- and light-resistant

- Suitable for nearly all fiber types

Cons:

- Can contain hazardous compounds

- Some (like unregulated azo dyes) may release carcinogenic amines

- Often require strict wastewater treatment systems

We don’t see dye selection as a binary choice. We advocate for natural dyes when aesthetics, values, and heritage align—and use synthetic dyes when performance, durability, and regulatory compliance demand it. The key lies in applying the right chemistry to the right fiber, for the right product and ensuring safety and sustainability at every stage. That’s where Deepwear’s team and on-ground inspection network come in.

What Are the Best Dyes for Fashion Fabrics in 2025?

There is no one-size-fits-all answer. The best dye depends on the fiber type, usage, design vision, and sustainability priorities of your brand. Here’s a quick guide:

- Reactive dyes are ideal for cotton and natural fibers when brightness and wash-fastness matter.

- Vat dyes are best for denim and outerwear needing deep, durable color.

- Disperse dyes excel on polyester and are often used in sublimation printing.

- Acid dyes are perfect for silk, wool, and nylon in luxury or lingerie applications.

- Natural dyes offer unique storytelling and biodegradability—but with limits in scalability and fastness.

At Deepwear, we can help brands navigate these choices through fiber-specific dyeing methods, qualified partners, and lab-controlled processes—ensuring that color performance aligns with your product’s goals. In the next section, we break down the most widely used dye classes in fashion, explaining how each works, which fibers they suit best, and how we manage quality and compliance at every stage.

What Are the Main Dye Classes and How Does Deepwear Ensure Quality?

Every fiber type reacts differently to dye classes. Deepwear works closely with labs and mills to ensure dye selection is not only fiber-compatible but also optimized for safety, durability, and regulatory compliance.

1. Acid Dyes:

How it Works: Work in acidic solutions; dye molecules form ionic bonds with protein-based fibers.

Used On: Wool, silk, nylon

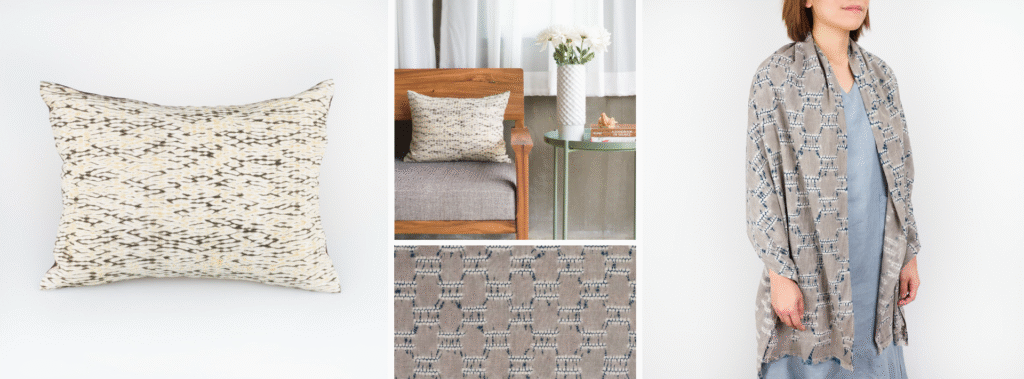

Deepwear Insight: Ideal for soft, luxurious finishes like cashmere shawls, silk slips, or fine lingerie. Our team can ensure proper pH control and exhaust dyeing methods to maintain both vibrancy and fastness.

2. Basic (Cationic) Dyes:

How it Works: Positively charged dye molecules attach to negatively charged fiber sites, often requiring a mordant or pretreatment.

Used On: Acrylics, modified polyesters, jute

Deepwear Insight: These dyes produce rich, vivid colors but are vulnerable to fading without precise control. We implement lab-controlled dyeing with post-fixatives for long-term fastness—especially in home décor or novelty textiles.

3. Direct Dyes:

How it Works: Water-soluble and contain sulfonic acid groups that form hydrogen bonds with fibers.

Used On: Cotton, viscose, nylon

Deepwear Insight: Popular for quick, economical production—especially in fast fashion. However, direct dyes are prone to bleeding, so we always recommend post-dye treatments to boost wash and rub fastness.

4. Reactive Dyes:

How it Works: Form covalent bonds with the fiber—creating a permanent chemical link.

Used On: Cotton, viscose, silk

Deepwear Insight: Our go-to choice for high-quality exports, especially when brands need long-lasting brightness and wash resistance. Best applied in GOTS- or OEKO-TEX–certified facilities where process control is robust.

5. Vat Dyes:

How it Works: Initially insoluble; reduced in a vat, applied to fiber, then oxidized to fix color.

Used On: Cotton (especially denim), viscose, silk

Deepwear Insight: Essential for denim and outerwear. Our teams can monitor on-site oxidation and rinsing to prevent streaking, fiber damage, or environmental runoff.

6. Disperse Dyes:

How it Works: Fine pigment-like particles dispersed in water and absorbed under heat and pressure.

Used On: Polyester, acetate, nylon

Deepwear Insight: Common in sublimation printing and vibrant athleisurewear. We work only with mills equipped for pressurized dyeing to eliminate spotting and uneven uptake.

7. Azoic Dyes:

How it Works: A two-step process where the dye is formed on the fiber via diazotization and coupling.

Used On: Cotton, viscose

Deepwear Insight: Known for rich reds and oranges—but risky if misused. We can audit suppliers for azo-free compliance and validate certifications like ZDHC, REACH, or Bluesign.

8. Solvent Dyes:

How it Works: Dissolved in non-polar organic solvents rather than water.

Used On: Plastic trims, synthetic labels, coated accessories

Deepwear Insight: Not used for main garment fabrics but crucial for logo applications, hang tags, and trims. Our supplier library includes solvent-dyed elements that meet ROHS and REACH safety thresholds.

9. Sulfur Dyes:

How it Works: Reduced in alkaline solution to dye form; reoxidized on fiber to develop color.

Used On: Cotton, viscose

Deepwear Insight: Durable and economical for workwear or uniforms in dark shades. However, these dyes can weaken fabrics over time. Our team can test for both tensile strength and color retention during AQL inspections.

10. Mordant Dyes:

How it Works: Require a metal salt (mordant) to fix dye to the fiber.

Used On: Wool, silk, cotton

Deepwear Insight: Rarely used in industrial production due to environmental concerns. But we support artisan clusters in India and Southeast Asia where heritage dyeing—including alum or iron mordants—are part of textile tradition. These are documented in our supplier catalog.

Deepwear’s Approach to Dye Selection & Sourcing

At Deepwear, dye selection is a rigorous process grounded in science, fashion fabric chemistry, and strategy. Here’s how we can deliver results you can rely on:

- We can build custom tech packs for every product, specifying dye type based on fiber, usage, and regional compliance.

- We can work with audited dye houses—GOTS-, OEKO-TEX-, ZDHC-, and Bluesign-certified.

- We can supervise lab dips and strike-offs, so color expectations match production realities.

- We can test fastness properties—wash, rub, perspiration, and light resistance—before signing off on any bulk run.

- We can offer clients access to low-impact dye alternatives—from plant-based indigo to eco-friendly dyeing solutions that reduce water and chemical use.

Why does this matter? Because Deepwear operates in 17 manufacturing countries, with local teams that can do:

- Mill audits

- In-person chemical compliance checks

- Real-time troubleshooting if dyeing issues arise mid-run

We maintain a living catalog of manufacturers and dye houses, not just based on capacity but also on technical ability and traceable performance. This is more than consulting—it’s control on the ground provided by your textile dyeing partner.

To explore our sourcing and QA workflows, visit our Manufacturing Network or Book a Strategy Session with our team.

What Happens When Dye Fastness Fails?

Dye selection isn’t just a color decision—it’s a performance commitment. If the chosen dye doesn’t adhere properly to the fabric, the result can be disappointing at best and disastrous at worst.

Fastness refers to a dye’s resistance to external influences. There are several types every brand should be aware of:

- Wash Fastness: Determines how well the color stays after repeated laundering.

- Light Fastness: Measures resistance to fading under sunlight or UV exposure.

- Rub Fastness (Crocking): Indicates how much dye transfers through friction.

- Perspiration Fastness: Assesses how color holds up against human sweat—especially critical in activewear and summer collections.

Even if your colors are vibrant during sampling, fastness failures in production can lead to:

- Garments bleeding or fading prematurely

- Negative reviews and costly returns

- Damage to your brand’s reputation for quality

With our on-the-ground teams in over 17 key production hubs can audit mills, supervise lab dips, and can oversee pre-production testing to identify any weaknesses in dye chemistry or application technique. We don’t leave it to chance.

Our AQL inspections can go beyond basic color checks—we include fastness testing protocols as part of our QA workflows. If a dye process isn’t performing, we intervene early—before garments hit the market.

Want reliable color every time? This is exactly why our clients trust Deepwear’s sourcing network. We help brands make informed decisions from dye house to delivery, ensuring what you envisioned is what your customer receives.

For more on how we build reliable production workflows, see our consulting services or browse our global manufacturer catalog where dye capability and certifications are listed per vendor.

What’s Next? A Look at Emerging Dyeing Technologies

The path to more sustainable dyeing is not linear—and there’s no single fix. While chemical innovation plays a role, findings from the UK Fashion and Textile Association (UKFT, 2024) highlight that energy and water efficiency measures may yield a greater environmental impact than dye reformulation alone.

Emerging technologies are beginning to reshape the sector, addressing different parts of the problem:

- Waterless dyeing techniques are gaining traction, reducing both water consumption and effluent discharge.

- Cleaner heating sources and machinery upgrades show promise in cutting thermal energy use, especially in plants still reliant on coal-based systems.

- Nanotechnology and synthetic biology are being tested to create novel pigment systems with lower toxicity and the potential for recyclability.

- Colourant recycling, though still at a low technology readiness level, could allow for dye extraction at end-of-life, supporting fibre-to-fibre chemical recycling.

Yet even the most promising solutions often struggle to scale. Many are incompatible with existing factory setups, requiring costly retrofitting or extensive pilot programs. There’s also a performance gap—several bio-based or alternative pigments fall short in meeting the durability, fastness, or colour vibrancy expected in commercial applications.

What’s clear is that innovation must go beyond just replacing one dye for another. The entire dyeing stage must be decarbonized, and solutions must align with Scope 3 emissions goals. Any new technology needs to integrate seamlessly into current production lines—without compromising efficiency or product quality.

As innovation continues, Deepwear monitors emerging dyeing technologies and works closely with trusted factory partners—ready to explore new systems when they prove viable and scalable.

Conclusion

Choosing the right dye isn’t just about aesthetics—it’s about performance, compliance, and brand protection. A poor dye choice can lead to bleeding fabrics, failed lab tests, or environmental red flags that stall your production. That’s why Deepwear doesn’t leave it to guesswork.

We partner with brands at the development stage which can help with fiber-specific dyeing protocols, identify certified dye houses, and oversee lab dips, fastness testing, and bulk production across 17+ manufacturing countries. Our network doesn’t just offer capacity—it delivers technical accuracy, traceable results, and on-site control when issues arise.

Ready to achieve colorfast, compliant, and sustainable fabric dyeing?

Book a strategy call with Deepwear’s sourcing consultants or browse our global dyeing partners today.