Long before the spinning jenny or fast fashion, hemp was already being woven into human history. From the sails of ancient ships to the robes of early artisans, this fiber has clothed entire civilizations. And now, thousands of years later, it is experiencing a quiet, confident revival — not in dusty archives, but in some of fashion’s most future-facing collections.

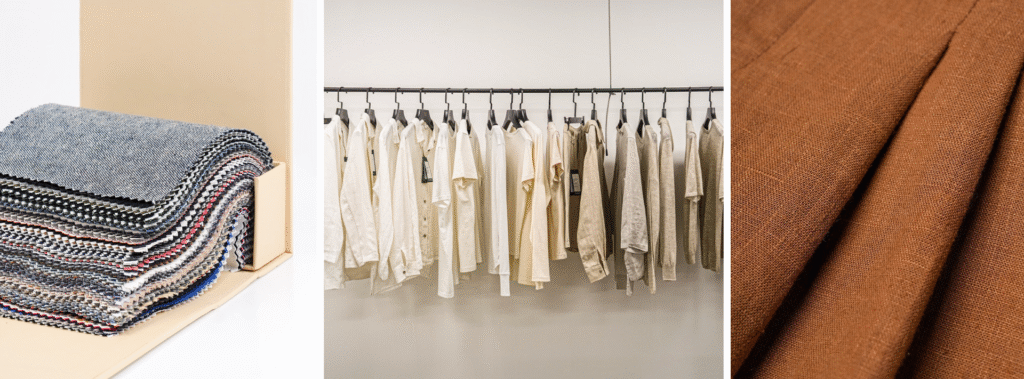

Hemp is showing up in all the right places: in elevated streetwear, where structure meets fluidity; in luxury loungewear, where texture matters as much as comfort; and increasingly, in one of fashion’s most demanding categories: denim. It’s proving that sustainability doesn’t have to compromise strength or style.

At Deepwear, we’ve watched hemp move from niche curiosity to next-big-thing across Europe and the US. Designers are no longer asking if they can work with hemp — they’re asking how to scale it beautifully and responsibly.

What Exactly Is Hemp Fabric?

Hemp fabric is made from the stalks of Cannabis sativa, but not the psychoactive variety. The type used for textiles contains only trace amounts of THC and is grown specifically for industrial use. It belongs to the bast fiber family, alongside linen, jute, and flax. These are plants whose inner bark yields strong, pliable fibers that can be spun into threads and woven into cloth. Like its bast cousins, hemp offers a naturally textured finish that falls somewhere between linen and raw canvas.

The result? A fabric that holds shape with quiet confidence. It’s breathable, yet structured. It softens with wear, yet retains its integrity. And it performs just as well in a tailored overshirt as it does in relaxed denim or heavy-duty utility wear.

Why Hemp Is Sustainability’s Strongest Fiber (Literally)

If fashion wants a material that’s as kind to the planet as it is to the skin, hemp is hard to beat. It’s one of the most resource-efficient natural fibers available today — and that’s only part of the story.

Here’s why hemp stands out among sustainable materials:

- Low Water Usage:

Hemp needs significantly less water than conventional cotton to grow. While cotton is notorious for its thirst — requiring over 2,700 liters of water for a single t-shirt — hemp thrives with minimal irrigation. - Higher Fiber Yield per Acre:

Hemp outperforms cotton and flax by delivering significantly more usable fiber from the same amount of land. This means farmers can harvest more raw material while conserving precious farmland, boosting both profitability and sustainability. - Soil-Regenerating Growth:

Hemp’s robust root system penetrates deep into the earth, anchoring soil and reducing erosion naturally. As the plant grows, it aerates the soil, and when its leaves fall and decompose, they return vital nutrients—enriching the land and supporting healthier future harvests. - Fast Growth Cycle:

Hemp matures in just 90 to 120 days, allowing for multiple harvests per year in the right climate. This rapid growth makes it one of the most renewable raw materials in the textile world. - No Need for Pesticides:

Naturally pest-resistant, hemp can be grown without synthetic chemicals. This means cleaner runoff, less soil degradation, and reduced harm to nearby ecosystems. - True Earth-Friendly Biodegradability:

Unlike synthetic fabrics that linger in landfills and oceans, hemp fibers break down swiftly and safely at the end of their lifecycle.

But this isn’t just a case of environmental virtue signaling. Hemp also delivers on performance and wearability:

- Durability:

Hemp is one of the strongest natural fibers on the market. It resists stretching, tearing, and abrasion, making it perfect for workwear, outerwear, and — increasingly — denim. - Softens With Wear:

While hemp starts out structured and slightly coarse, it softens beautifully over time, developing a lived-in texture without weakening. - Natural Resistance to UV and Mildew:

Clothes made from hemp retain color better under sunlight and stay fresher longer in humid climates. - Adaptable to Dye and Finishes:

Hemp takes well to natural dyes and modern finishing processes, allowing designers to blend traditional craftsmanship with contemporary color stories.

In a world where consumers are increasingly savvy — asking not just how garments look, but how they’re made — hemp answers both questions with quiet confidence. It is a fiber that embodies balance: strength and softness, sustainability and style, heritage and innovation.

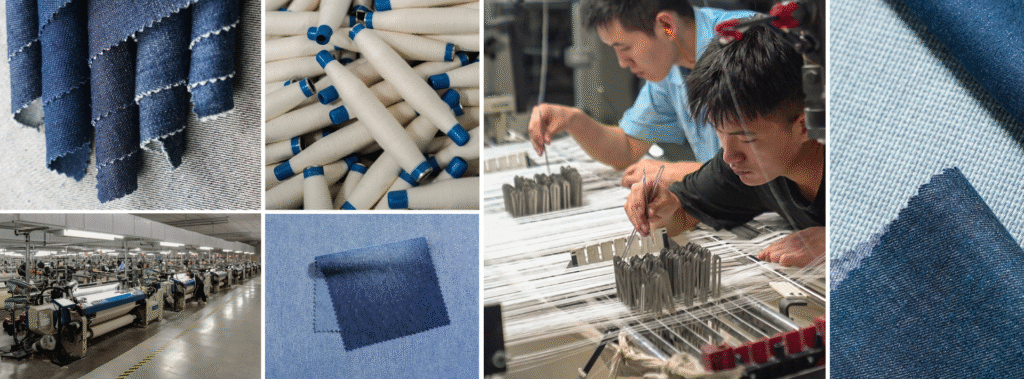

How Hemp Is Made

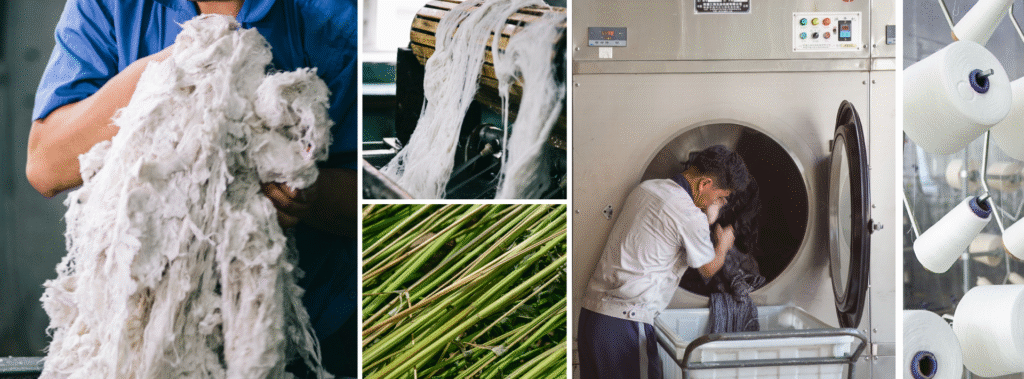

Hemp’s transformation from tall, wind-swept stalks to high-performance textile is a journey rooted in ancient tradition — and now shaped by innovation.

It begins in the field. Hemp grows fast — typically within 90 to 120 days — and its towering stalks house long, strong bast fibers, the same family as flax and jute. After harvest, the plant undergoes retting, a separation process that breaks down the pith to free the fibers. Traditionally done using dew or water, modern versions now use enzymes and low-impact methods to minimize environmental costs.

Once retted, the stalks are broken and combed to extract and align the fibers. These are then spun into yarn often with blended or specialized textures, and woven or knitted into fabric.

Thanks to recent innovations, this age-old process is faster, cleaner, and more consistent, creating textiles that are finer, softer, and more versatile than ever before.

Hemp’s Feel, Form, and Function

There’s a quiet poetry to how hemp moves and it’s matched by hardwearing performance.

This is a fiber that wears in, not out. It softens over time without weakening, making it a rare blend of comfort and resilience. The material breathes well, resists UV rays and mildew, and naturally regulates body temperature, making it suitable for both everyday basics and high-performance garments.

Hemp is also strong — up to eight times stronger than cotton — and holds structure beautifully. Whether you’re designing soft-tailored pieces or working with structured denim, it retains form without stiffness.

It holds its own among other natural fibers:

- Compared to cotton: Hemp uses far less water, lasts longer, and doesn’t require chemical treatments.

- Compared to linen: It’s just as breathable, but stronger and more versatile across weights.

- Compared to bamboo: It avoids the chemical-heavy processing bamboo often needs to become fabric.

(For more comparisons, see our Top Sustainable Fabrics for 2025 blog here)

Opportunities and Challenges by Region

Drawing on current trade data from the Observatory of Economic Complexity (OEC) and market research from the Centre for the Promotion of Imports from developing countries (CBI), this overview focuses on hemp production and trade opportunities in key countries where Deepwear maintains offices or is active in nearby markets.

CHINA

Pros:

- One of the world’s top hemp producers and exporters of raw hemp fiber and yarn.

- Long-standing experience in industrial hemp cultivation and large-scale textile processing.

- Established global logistics and export capabilities.

Cons:

- Increasing scrutiny over environmental practices and sustainability compliance.

- Political and trade tensions with the EU and US affecting buyer confidence.

- Quality inconsistencies in lower-cost suppliers.

INDIA

Pros:

- Emerging interest in hemp as a sustainable textile, with rising government support in states like Uttarakhand and Himachal Pradesh.

- Competitive labor costs and deep experience in natural fiber processing.

- Cultural familiarity with hemp (locally known as “bhang”) for various traditional uses.

Cons:

- Limited large-scale cultivation and supply chains still in early development.

- Legal and regulatory uncertainty over THC content restrictions.

- Export infrastructure for hemp textiles is less mature than for cotton.

THAILAND

Pros:

- Legalized hemp cultivation in 2021, creating new opportunities for industrial applications including textiles.

- Strategic location in ASEAN with access to regional supply chains and logistics.

- Government incentives and support for cannabis and hemp-based industries.

Cons:

- Still developing technical capacity for high-quality textile-grade hemp fiber.

- Limited domestic experience in hemp yarn production and weaving.

- Fragmented supply chain lacking scalability.

VIETNAM

Pros:

- Advanced garment manufacturing sector with a focus on exports to the US and EU.

- Well-integrated textile value chain and favorable FTAs (e.g., EVFTA).

- Experience in processing other bast fibers like flax and jute.

Cons:

- Limited domestic hemp cultivation; raw hemp often needs to be imported.

- Still early in establishing hemp-specific standards and suppliers.

- Strong competition from other sustainable materials (e.g., bamboo, recycled PET).

MOROCCO

Pros:

- Legal reforms (2021) now allow regulated hemp cultivation for industrial use.

- Geographic proximity to EU markets and cost-effective labor.

- Strong potential for export positioning as a nearshore supplier to Europe.

Cons:

- Hemp textile infrastructure is still minimal.

- Legal framework and licensing remain bureaucratic and region-specific.

- Limited expertise in large-scale textile conversion from hemp.

EUROPEAN UNION

Pros:

- Europe is a growing hub for sustainable fashion, with high consumer demand for eco-friendly textiles.

- Hemp cultivation in countries like France, Romania, and the Netherlands is mature and expanding.

- The EU’s Circular Economy Action Plan requires textiles sold in the region to be more durable, repairable, and recyclable by 2030.

- Import data from the OEC shows strong European interest in finished hemp products, with key markets including Germany, France, the Netherlands, and Spain.

Cons:

- Stringent requirements for sustainability certification (GOTS, OEKO-TEX, REACH).

- Higher production and labor costs.

- Competitive market with many established sustainable brands.

The Deepwear Advantage: Sourcing Hemp with Global Agility

The global textile industry is undergoing a transformation — and hemp is leading the charge. Once relegated to the margins, hemp fabric has re-emerged as a cornerstone of future-forward fashion. The numbers speak for themselves: valued at USD 21.89 billion in 2024, the hemp fabric market is projected to reach USD 393.67 billion by 2034, growing at an astounding CAGR of 33.5% according to Market Research Future.

At Deepwear, we’re uniquely positioned to help brands tap into this momentum.

With offices and sourcing teams across India, China, Vietnam, Portugal, and beyond, we make hemp sourcing not just possible — but easy. Whether it’s hemp canvas, jersey, or even hemp denim, our global presence means we can match you with the right supplier, the right fabric, and the right price point — fast.

From sustainable streetwear to high-performance blends, our deep-rooted relationships with certified mills ensure traceability, compliance, and consistent quality. You don’t need to navigate the hemp supply chain alone. With Deepwear, you gain a nimble partner that already has boots on the ground.

Want to build with hemp? We’ve already built the bridge. Schedule a consultation with us today.