Learn the key factors that define small fashion brand success — from costing and supplier credibility to sustainability and agility. Deepwear helps emerging labels grow with clarity, ethics, and confidence.

Launching a fashion brand is exciting, but small and emerging labels face unique challenges — from managing costs to sourcing reliable factories and maintaining product quality. While no partner can guarantee overnight success, Deepwear can help brands navigate these challenges with expertise, connections, and practical guidance. By understanding the fashion brand success factors that shape long-term growth, small brands can make informed decisions that protect margins, quality, and reputation. In this guide, we explore seven critical elements that influence brand success, and explain how Deepwear’s hands-on sourcing, fashion business consulting, and production support help small brands thrive responsibly and efficiently.

In this blog we cover:

- Cost planning and budget clarity to avoid unexpected expenses

- Building reliable supply chains and factory relationships

- Maintaining high product quality with technical support

- Securing supplier credibility for better MOQs and pricing

- Agility and responsiveness in a rapidly changing market

- Implementing sustainable production practices

- Long-term strategy and partnership for steady brand growth

What Factors Really Drive Success for Small Fashion Brands?

While creativity and vision are essential, the day-to-day realities of launching and running a fashion brand require careful attention to practical and strategic factors. Small labels often face challenges that can slow growth or impact quality, from cost management and supplier credibility to navigating shifting market demands. The seven areas below highlight the elements that most influence long-term success — and show how Deepwear can help brands turn these challenges into actionable, manageable steps.

1. Cost Planning and Budget Clarity

Unexpected costs can sink a small brand before it even reaches the market. Deepwear can guide clients through garment costing, including fabrics, trims, packaging, and logistics. We provide multiple MOQ scenarios and cost breakdowns so founders can see how production volume, materials, and add-ons impact unit costs. By clarifying where it makes sense to invest in engineering or premium features — and where simplification preserves margins — Deepwear can help brands plan confidently without overextending.

2. Reliable Supply Chain and Factory Relationships

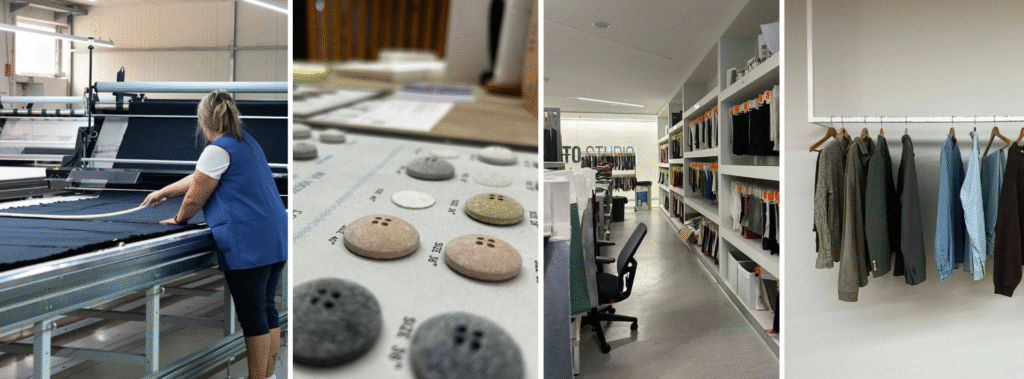

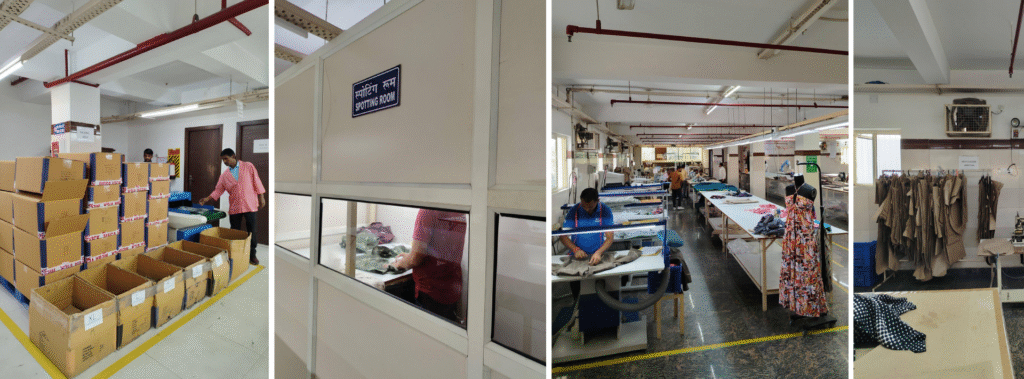

Consistency and accountability are essential to delivering quality products on time. Our global network of trusted factories and on-the-ground teams ensures production is closely monitored, reducing delays, miscommunication, and risk. We maintain long-term relationships with suppliers, giving small brands access to reliable partners that might otherwise prioritize larger clients.

3. Product Quality and Technical Support

From fit and grading to finishes and stitching, product quality directly impacts customer satisfaction. Deepwear supports brands through tech pack development, sampling, and production oversight. Our team helps small labels identify potential production challenges, advises on workmanship, and ensures that each batch meets the intended standard — protecting both quality and brand reputation.

4. Credibility with Suppliers

Emerging brands often struggle to secure favorable MOQs, pricing, and lead times. Deepwear acts as a professional representative in supplier negotiations, giving factories confidence in the brand’s seriousness and long-term potential. This advocacy opens doors to more flexible production options and better collaboration opportunities, even for smaller runs.

5. Agility and Responsiveness in a Changing Market

Fashion moves fast, and consumer preferences, materials, and costs can shift unexpectedly. Deepwear’s 17 offices worldwide enable brands to pivot relatively quickly — whether sourcing alternative materials, adjusting order volumes, or responding to timeline changes. This agility allows small brands to stay competitive without sacrificing quality or consistency.

6. Sustainable and Ethical Production

Consumers increasingly value brands that prioritize ethical manufacturing and sustainability. Deepwear helps brands connect with factories that meet social and environmental compliance standards and advises on material choices and production strategies that minimize waste and support responsible growth. By building a supply chain aligned with values, small brands can meet consumer expectations without overcomplicating operations.

7. Long-Term Strategy and Partnership

Success is built over time. Deepwear works with brands season after season, helping refine production processes, improve costing strategies, and optimize supply chain management. By acting as a trusted partner rather than a transactional middleman, we provide the guidance and resources that help brands grow steadily while maintaining quality, efficiency, and ethical standards.

How Emerging Brands Navigate Growth

These examples are based on actual brands Deepwear has supported, anonymized to protect confidentiality, and show how a strong sourcing partner can turn obstacles into manageable, strategic steps.

Example 1: Improving Factory Reliability

One emerging label had struggled for years with multiple factories, experiencing delays, quality inconsistencies, and corner-cutting. Our team provided hands-on guidance from sampling through final shipment, helping the brand:

- Negotiate practical MOQs to reduce costs and waste.

- Identify and secure reliable factory partners.

- Refine production processes to maintain consistent quality.

Outcome: The brand was able to streamline production, control costs, and deliver products that met their standards — all while freeing the founders to focus on design and market strategy.

Example 2: Coordinating Multi-Category Production

An accessories brand wanted to launch jewelry, scarves, and leather goods across multiple countries. Deepwear coordinated production in India, Morocco, and Thailand, providing:

- Technical guidance on design and material selection

- Oversight of quality across factories

- Logistics and timeline management to meet delivery goals

Outcome: The brand successfully produced high-quality products across categories, maintained operational efficiency, and gained the confidence to plan future launches.

Key Takeaways for Small Brands

- Even emerging labels can achieve professional-grade production with the right guidance.

- Strategic support, supplier advocacy, and hands-on oversight reduce operational risks.

- Careful planning and collaboration create a strong foundation for long-term growth.

Looking to build your brand with confidence and structure? Deepwear’s sourcing consultants can help you turn creative vision into scalable, ethical production — from first samples to full collections.

How Deepwear Makes a Difference

No two production journeys are identical. Deepwear focuses on practical support, credibility, and careful oversight rather than empty promises. We help small brands:

- Understand garment costing and manage MOQs efficiently

- Navigate supplier negotiations and build long-term factory relationships

- Maintain high product quality across every batch

- Access agile sourcing solutions in multiple regions

- Implement ethical and sustainable practices without overcomplicating operations

- Build a growth strategy based on careful planning, not shortcuts.

Emerging brands face a lot of headaches, but the Deepwear team can help alleviate these so they focus on what they love: designing, marketing, and growing their products. With Deepwear handling sourcing, production oversight, and supplier coordination, founders can bring their creative vision to life without getting bogged down in operational stress.

Ready to take your fashion brand from concept to consistent growth? Book a strategy call with Deepwear’s consulting experts or explore our full range of sourcing and production management solutions today.