Shaping the Future of the Fashion Industry

Innovative fabric printing techniques have gradually redefined the fashion landscape over the last decade. They are as groundbreaking as they are eco-sensible. As the sector marches toward a more technologically and sustainably advanced future, fashion businesses must proactively embrace these trends to remain competitive.

In today’s article, we will explore five revolutionary printing methods. Methods that enable not only aesthetic excellence but also meet the rising demands for environmental responsibility in the fashion industry. For companies like Deepwear, well-known for providing expert guidance in integrating advanced printing methods, this evolution presents a significant opportunity. So, without further ado, let’s delve into the first printing method.

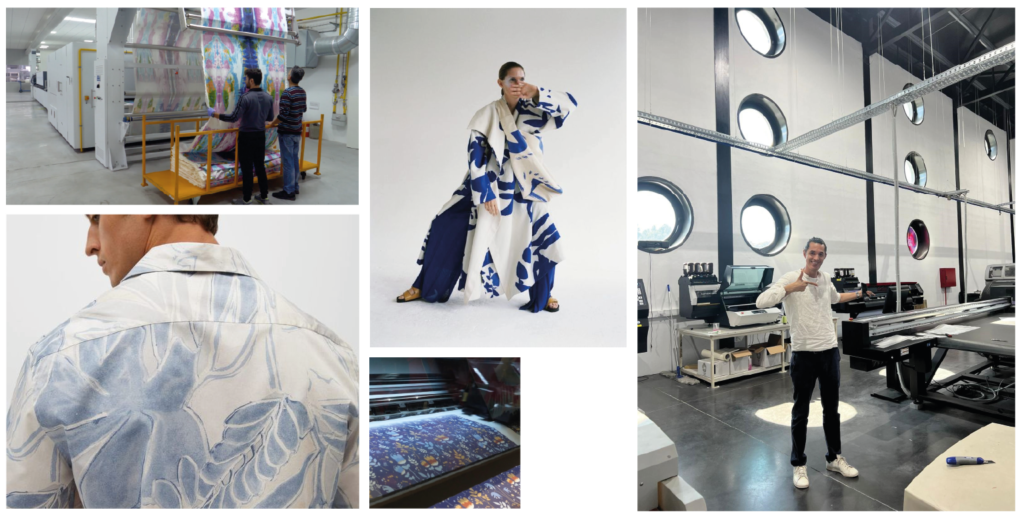

Sustainable Digital Printing on Fabric: A New Chapter of Precision and Eco-Friendliness on Innovative Fabric Printing Techniques

The digital textile printing technique has recently set a new benchmark for fabric design. This innovative method is lauded for its precision. It enables unlimited color variations and awe-inspiring patterns never before imagined. However, these aren’t the only advantages of digital printing on fabric. Beyond its endless design capabilities, this technique exemplifies sustainable fabric printing.

Digital textile printing reduces the environmental impact compared to conventional methods by using fewer dyes and less water. This allows fashion brands worldwide to quickly respond to fast-changing trends with rapid prototyping. Thus reducing overproduction and textile wastage—is crucial in a market where speed and sustainability are paramount.

The latest textile printers are designed to handle a broad range of fabrics, including delicate ones that were once challenging to print. This enhanced flexibility offers personalizations and customizations on a scale previously unimaginable.

Water-Based Burn Out Printing on Fabric: Skin-Safe and Eco-Friendly

With consumers’ growing consciousness towards well-being and the environment, the water-based burnout method emerges as a preferred sustainable fabric printing choice. This technique employs water-based inks, which are gentler on the skin and the environment. Controlled heat is used to create mesmerizing translucent patterns on cotton blends.

Once again, this method embodies an environmentally friendly ethos without compromising the delicate artistry of textile design. Water-based burn-out printing on fabric continually evolves with new formulations that provide a better hand feel and longer-lasting prints. This not only improves garment comfort but also enhances durability, reducing the need for frequent replacements.

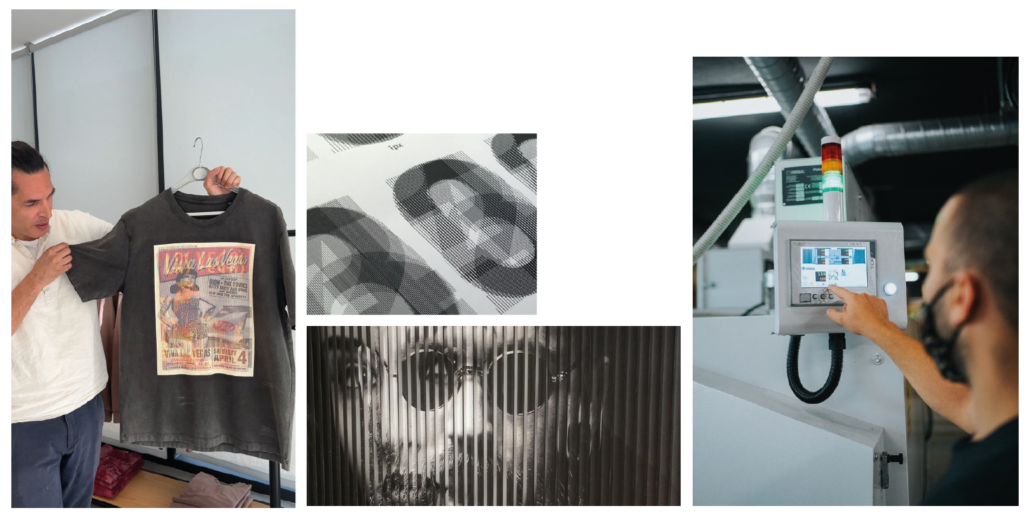

Lenticular Printing: Interactive Garments in Motion and Innovative Fabric Printing Techniques

Lenticular printing on fabric is another innovative method that breathes life into garments. It makes them truly captivating by creating an illusion of depth and motion. This groundbreaking technique allows for the production of images that change or move when observed from different angles, providing a visually engaging experience.

Deepwear’s exploration and expertise in interactive garments offer fashion brands numerous new possibilities. Possibilities allow for apparel that transforms as the viewer’s perspective shifts, delivering surprise to everyday clothing.

The ability of lenticular printing to combine several images into one print allows for extraordinary storytelling through the fabric. This way garments tell varying tales from different viewpoints. Fashion designers worldwide find this particularly compelling for marketing campaigns, revealing more than what catches the eye at first glance.

Explore the possibilities of this technique with our Founder and CEO Thoray Sacoor here.

Rubber Printing on Fabric: The New Frontier of Durability and Eco-Friendliness

Rubber printing is a game changer in fabric printing due to its robust and eco-friendly approach. This innovative technique allows for a raised and textured effect known for its unique quality and durability.

Over the years, modern fashion advancements have refined rubber printing on fabric. Think elimination of hazardous chemicals, reduced wastage, and sped up production, thus aligning it with the environmentally aware values of today’s fashion market. The latest formulations of rubber printing incorporate water-based silicone inks, which are kinder to the environment. Additionally, the method has been improved for enhanced washability and greater comfort, ensuring the printed area of the garment stays flexible and doesn’t crack over time.

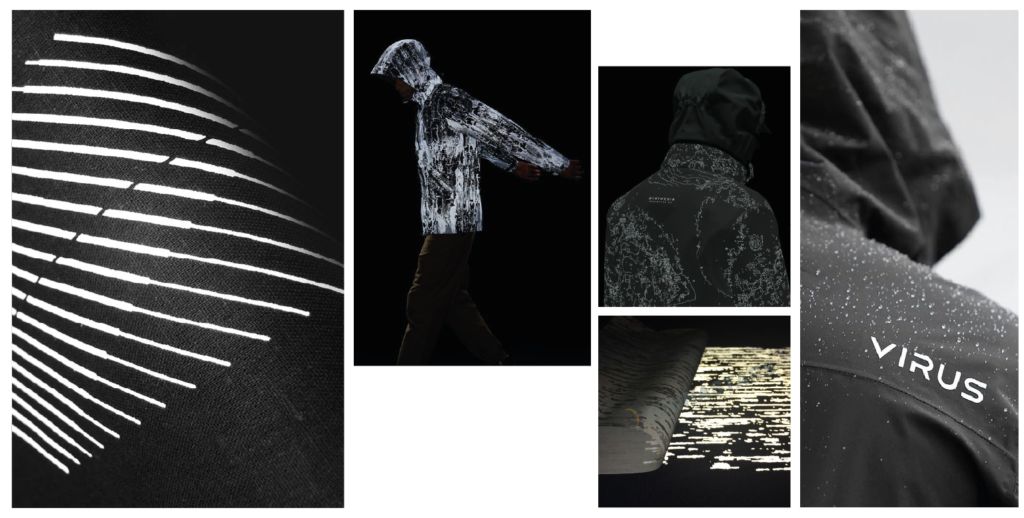

Reflective Printing on Clothing: Safety and Style in One

Reflective textile printing is a true revolution in reflective athletic garments, seamlessly combining safety with style. This innovative approach is indispensable, creating high-visibility wear crucial for outdoor and nighttime physical activities.

Materials like “3M Scotchlite™” and “Reflexite™” are integrated into fabrics. The purpose being is to enhance safety while adding a stylish touch to athletic wear, combining practicality with the contemporary trends of 21st-century fashion. As athletic attire continues to blur the lines with casual wear, reflective printing is set to become a key player in this realm.

The versatility of reflective prints allows for incorporating patterns that reveal their functionality only when illuminated, making them a sophisticated addition to any modern wardrobe. Designers today experiment to create day-to-night outfits, where reflective aspects present a concealed statement by day and a practical element by night.

Final Thoughts

Today’s fashion future is continually shaped by the innovative garment printing techniques discussed in this article. Eco-friendly fabric printing, digital printing, interactive lenticular shapes, sustainable burn-out prints, detailed rubber designs, and functional reflective patterns are not passing trends but significant steps towards a more responsible fashion. Thanks to these methods, fashion brands can craft high-quality, eco-friendly, and captivating designs that enhance the consumer experience.

At Deepwear, a company that assists fashion brands in adopting these innovative technologies, the potential of advanced garment printing techniques is immense. By partnering with Deepwear, businesses within the fashion sector can simplify the process of incorporating these practices into their production line, ensuring a forward-thinking approach that is both environmentally friendly and stylish.”