Recycled denim, silver and gold are transforming modern fashion — but production is complex. This guide explains costs, challenges, quality standards, and how Deepwear supports brands building high-impact circular collections.

Fashion’s shift toward circularity has evolved from an ethical preference into a market expectation. But while the demand for recycled textiles, silver, and gold is rising, the actual production process is far more complex than it looks on the surface.

In this blog we cover:

- The different categories of recycled materials and how they behave

- The real challenges behind recycled textile and metal production

- Why recycled doesn’t always mean cheaper — and what costs to expect

- Essential quality and testing standards for circular materials

- What makes factory collaboration more complex

- Practical next steps for brands ready to explore recycled production

- How Deepwear supports recycled-material projects with realistic, case-by-case guidance

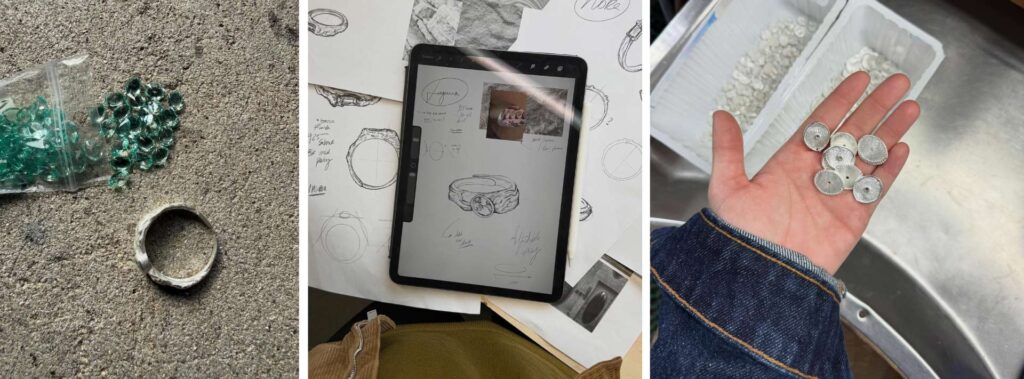

We’ve collaborated with brands producing recycled denim textiles, reclaimed silver, and recycled gold jewelry. Each project challenged us — and pushed factories, artisans, and even local supply chains into fresher, more innovative territory. Cleaning, sorting, repairing, melting, reforming, and re-assembling recycled materials is time-intensive, labor-heavy, and requires factories willing to take on the extra steps.

Still, the payoff is enormous: lower footprint, higher brand value, and a story consumers genuinely connect with.

Below is a complete guide to the realities of working with recycled materials and how to approach this journey strategically.

1. Understanding Recycled Material Categories

Before diving into production, it’s crucial to differentiate between the main material categories:

Recycled Metals

- Recycled silver: Typically sourced from old electronics, jewelry scraps, industrial waste. Needs purification before remelting.

- Recycled gold: Highly sustainable because gold can be infinitely recycled without losing quality.

Why it works well: Metals regenerate into the same purity level as virgin material.

Recycled Textiles

- Recycled denim: Requires collection, sorting, removal of trims, cleaning, fiberization, and re-spinning.

- Recycled cotton blends: Often need multiple fiber sources to achieve stability.

Why it’s more challenging: Fiber damage, colour limitations, and variable quality.

If your brand is new to recycled material sourcing, start with metals or accessories, then scale into textiles as your production knowledge deepens. For brands still deciding which circular approach fits their goals, our guide Recycling vs. Upcycling: A Guide for Brands to Make Sustainable Fashion Choices offers a clear comparison of both pathways.

2. The Real Challenges Behind Recycled Textile Production

Producing recycled textiles isn’t a plug-and-play process. Common challenges include:

- Inconsistent fiber length → affects yarn quality

- Extra pre-processing (sorting, washing, re-fiberizing) → increases cost

- Fewer factories willing to do small batches

- Colour restrictions → fewer consistent shades unless re-dyed

- Higher MOQs due to machinery setup and blending needs

In our recycled denim collaborations, the most time-consuming part wasn’t weaving — it was finding a factory willing to slow down enough to sort, clean, repair, then process the material. Once they did, though, the outcome was deeply rewarding both creatively and environmentally.

If you’re interested in understanding MOQs more broadly, see Deepwear’s guide on “MOQ Made Simple: Managing Garments, Jewelry, and Packaging”.

3. Recycled Metals: Easier, But Still Not Effortless

Recycled silver and gold are more straightforward because:

- They have standardized global purity benchmarks

- They do not degrade after recycling

Local artisans often already have smelting and refining workflows

However, the hurdles include:

- Traceability because not all recycled metals are equal

- Certification such as FSC-CoC, RJC, SCS

Capacity because artisans may not handle high volume

Deepwear frequently works with artisans who specialize in recycled metals, but even they need adequate lead time for purification, melting, mold-making, and polishing.

4. Cost Implications: Recycled Doesn’t Mean Cheaper

A common misconception is that recycled materials reduce cost. In reality:

Recycled textiles may cost more because:

- Collecting waste materials is labour-heavy

- Sorting and cleaning are extra steps

- Re-spinning requires specialized equipment

Recycled metals may cost the same or slightly more than virgin metals because:

- Purification is energy-intensive

- Small-batch smelting raises per-unit cost

However, the value uplift—brand positioning, sustainability metrics, customer loyalty—makes the investment worthwhile.

5. Quality Considerations and Testing

Quality assurance becomes critical when using recycled materials because of variance.

For textiles:

- Perform tensile tests

- Check pilling resistance

- Confirm weave stability

- Colourfastness testing is essential

For metals:

- Test purity percentage (925 silver, 14k/18k gold)

- Inspect for porosity after casting

- Verify weight consistency

Working With Factories: What Makes It Different

Factories generally prefer virgin materials because they fit predictable workflows. Recycled materials introduce slower processes, higher risks, and more manual handling. That’s why finding the right supplier is usually the hardest part.

Key differences when working with recycled materials:

- More negotiations upfront

Factories may hesitate, worrying about fiber quality (textiles) or purity consistency (metals). We often need to negotiate special terms, timelines, or blended-material strategies.

- Expect slower production timelines

Especially for recycled fabrics — sorting, washing, and fiberizing add days or weeks.

- More trial and error

Recycled materials respond differently to washes, dyes, and machinery. - You might need multiple suppliers

One for sourcing the waste, one for processing it, and one for final production.

One for sourcing the waste, one for processing it, and one for final production.

Deepwear’s role is often to mediate these discussions, map realistic workflows, and ensure the brand’s vision is still achievable. While we can help identify potential suppliers, it’s important to note we always evaluate feasibility case-by-case — recycled projects require flexibility from all sides.

Thinking about launching a recycled denim or cotton project? Deepwear can review your brief and advise on realistic timelines, MOQs, and supplier options.

Practical Next Steps for Brands

If your brand wants to explore recycled textiles or metals, here’s the realistic, actionable path — based on what we’ve seen work best.

1. Start with a strong brief

Outline your product goals, material preferences, sustainability targets, and budget.

2. Choose your recycled category wisely

- Start with recycled metals if you’re new to circular materials

- Move into textiles when you have more production experience

3. Expect longer timelines and higher MOQs

Some suppliers may be flexible, but others require volume due to the labour involved. Use our garment costing explainer for brands to structure your expectations.

4. Sampling is non-negotiable

You will likely need multiple rounds. This is normal for recycled materials.

5. Deepwear can support supplier research

We won’t list recyclers publicly (as partnerships change frequently), but we can:

- Explore potential suppliers for you

- Initiate early conversations with factories

- Share feasibility feedback

- Outline negotiation paths

Because every recycled-material project is unique, we evaluate availability and willingness on a case-by-case basis. Some factories are open to experimentation; others need extensive discussions. What we can guarantee is process, effort, and honest assessments, not automatic availability.

6. Prepare for meaningful storytelling

The work behind recycled materials is deep, and customers should know it. Document it early.

What Are the Main Challenges in Producing Recycled Textiles?

The biggest challenges come from the inconsistent fiber quality, extra sorting, cleaning and re-fiberizing steps, and limited factory willingness to take on slower workflows. Deepwear helps brands evaluate timeline, MOQ and cost feasibility before production begins to avoid risk and delays.

What This Means for Your Brand

Working with recycled materials can be a strategic brand decision. Circular textiles and metals require more time, more negotiation, more testing, and more patience. But the result is a product that carries genuine impact: lower environmental footprint, higher consumer trust, and a story that no virgin material can replicate.

Brands that succeed in this space aren’t just chasing sustainability trends; they’re building long-term value. They plan ahead, communicate clearly with suppliers, set realistic expectations around MOQs and timelines, and collaborate with partners who understand both the creative and operational demands of recycled production.

Deepwear embraces these projects not because they are easy, but because they challenge the industry to do better. They push factories toward innovation, elevate artisanship, and allow brands to create something meaningful, not just marketable. If your brand is considering recycled materials, we’re here to help you navigate what’s possible, what’s practical, and what will truly support your vision.

If you’re exploring recycled textiles or metals and want clarity before investing, Deepwear can walk you through feasibility, factory willingness, realistic timelines, and sampling roadmaps. Share your brief with us — we’ll show what’s truly achievable, where, and under which terms so you can build circular collections without guesswork. Contact us today!