Learn how fashion brands turn denim wash defects into design opportunities. Deepwear helps brands recover batches through AQL inspection, eco-friendly dyes, and creative sourcing solutions.

Denim washing is a beautiful balancing act — part chemistry, part craftsmanship. But when something goes wrong, it can be costly. Uneven fading, unexpected streaks, or color inconsistencies can turn a promising collection into a problem.

At Deepwear, we understand that wash defects happen, especially for brands still finding the right manufacturing partners. But a mistake doesn’t always have to mean a loss. Some defects can be salvaged, creatively rebranded, or even transformed into unique, limited-edition pieces.

In this guide, we explore:

- Common denim wash defects and what causes them

- How to tell cosmetic issues from critical ones

- Quick ways to check your denim before AQL inspection

- How Deepwear helps brands recover from setbacks and prevent future ones

Common Denim Wash Defects and What Causes Them

In denim washing, each finish — from stone wash to acid wash — depends on precise control of chemicals, water levels, and timing. Even a small inconsistency can lead to unexpected results.

Here are some of the most common denim wash defects brands encounter:

- Uneven fading or patchy color — When some areas look lighter or darker than others. This usually happens due to uneven application of chemicals, inconsistent machine agitation, or drying issues.

- Streak marks — Long or cloudy lines that appear after washing. Often caused by poor distribution of stones or chemicals, or overloading the washing machine.

- Back staining — The inner fabric absorbs excess indigo dye, giving jeans a muddy or dirty appearance. This typically results from incomplete rinsing or dye redeposition during the wash.

- Unnatural crease or whisker marks — Creases that look harsh or misplaced rather than natural. This happens when the garment is folded or shaped incorrectly before washing.

- Bleach spots or over-whitening — Irregular white patches appear when bleaching agents aren’t evenly applied or properly neutralized.

- Rough or weakened fabric texture — When denim feels brittle, thin, or easy to tear. Overuse of enzymes, stones, or heat often causes fiber damage.

Not all these issues are catastrophic. Some can be turned into creative denim recovery opportunities — particularly if the batch remains structurally sound and the flaws only affect the surface appearance.

Looking to prevent the same issue next season? We work with trusted wash houses and manufacturers across Asia, helping brands maintain consistent quality while minimizing costly surprises. Explore our Catalogue.

Assessing the Damage: Cosmetic or Critical?

When denim washing doesn’t go as planned, the instinct may be to write off the entire batch, but that isn’t always necessary. The key is to identify whether the defect is cosmetic, meaning it only affects appearance, or critical, meaning it compromises quality, safety, or environmental compliance.

Cosmetic Defects (Recoverable)

Cosmetic defects are surface-level flaws that don’t affect how the garment performs, feels, or holds up over time. These are often minor inconsistencies that can still add character to the denim.

Examples include:

- Slight color variations between pieces

- Subtle streaks or uneven fading that still look natural

- Accidental vintage or worn effects that don’t reduce quality

With some creativity, these “imperfect” pieces can become valuable assets. They can be repositioned as limited editions, artisan washes, or upcycled collections — proof that no two garments are alike. When framed honestly, these small variations can strengthen a brand’s sustainability story and appeal to consumers who value authenticity over uniformity.

Critical Defects (Non-Recoverable)

Critical defects are deeper issues that go beyond appearance. They can weaken the fabric, cause irritation, or pose risks to both consumers and the environment.

Examples include:

- Chemical residues that cause skin irritation

- Over-bleaching or acid use that weakens fibers

- Dyes or finishes that fail safety or environmental standards

Products with critical defects should not reach consumers. Instead, brands should coordinate with their manufacturer to recycle or safely dispose of the affected pieces. At Deepwear, we guide clients through this process — ensuring materials are handled ethically and in line with environmental best practices.

Facing denim wash inconsistencies? Deepwear’s inspection experts can help identify which defects can be recovered and guide your next sustainable wash strategy.

Quick In-House Quality Check Before AQL Inspection

Before sending your batch for official AQL inspection, it helps to conduct a simple in-house review. This saves time, reduces rejection rates, and helps you understand the scope of defects before escalation.

A few practical steps:

- Check color consistency under neutral light. Compare multiple pieces side by side — artificial lighting can hide subtle differences.

- Feel the fabric texture. Overwashed denim may feel rough or weak in certain spots.

- Inspect seams and edges. Look for areas where chemicals may have over-penetrated or frayed threads appear.

- Smell test. Lingering chemical odor can signal incomplete neutralization or improper rinsing.

Once you have a clearer sense of your batch’s overall quality, you can confidently proceed with formal inspection or rework planning.

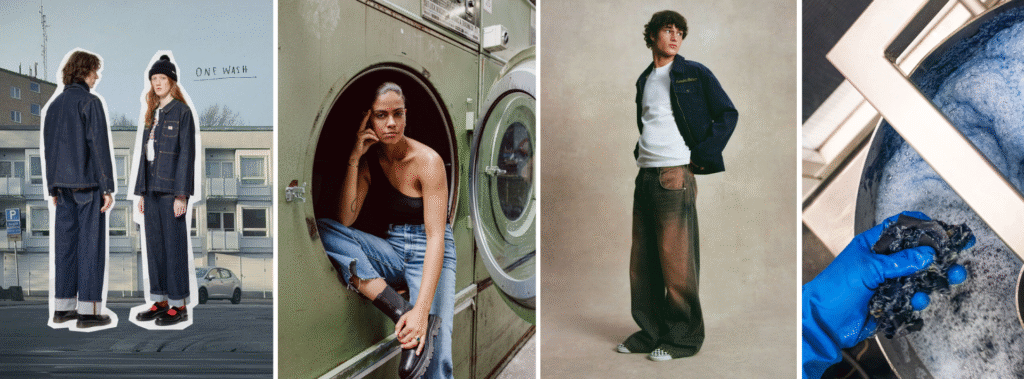

Turning Wash Defects into Opportunities

Sometimes, the best outcomes come from unexpected flaws. If your batch is structurally sound but visually inconsistent, it doesn’t have to be a total loss.

Here’s how creative brands have turned mishaps into wins:

- Reframe the story. Market the pieces as “artisan wash”, “vintage fade”, or “one-of-a-kind” editions. Consumers increasingly value authenticity and individuality.

- Introduce limited runs. Lean into the exclusivity — what started as an error can become a collector’s piece.

- Upcycle or patchwork. Combine uneven panels or rewash selected sections to create intentional contrast.

- Collaborate with artists or dye specialists. Some brands turn minor discolorations into hand-finished accents, giving the product a bespoke edge.

At Deepwear, we’ve seen brands regain full value — and even spark new design directions — by creatively reinterpreting cosmetic wash defects.

How Deepwear Minimizes Risk and Helps Brands Recover

Our team can inspect denim batches at multiple stages — from pre-wash to final packing. Our AQL-based inspection process ensures that clients receive consistent quality, with each batch evaluated for wash, color, fit, and finish.

If your brand has faced issues with another agency or manufacturer, Deepwear can step in to help:

- Batch recovery and re-inspection for salvageable products

- Sourcing of safer dyes and eco-friendly washing chemicals

- Technical consultation on wash recipes and production consistency

- Transparent reporting at every stage of quality control

Defects happen — but with the right partner, they don’t have to define your collection. At Deepwear, we help you turn every setback into an opportunity to rebuild stronger, smarter, and more sustainably.

If your denim brand has faced wash defects or quality inconsistencies, reach out to our team.

What Are the Most Common Denim Wash Defects and How Can Brands Recover Them?

Common denim wash defects include uneven fading, streak marks, and back staining. While some are cosmetic and can be creatively rebranded as limited-edition denim pieces, others require re-inspection or re-dyeing. Deepwear guides brands through AQL denim control, defect recovery, and eco-friendly denim washing practices that protect both quality and sustainability.

Turning Denim Defects into Design Wins

In denim manufacturing, mistakes don’t have to mean losses. With the right inspection process and creative strategy, brands can transform wash defects into opportunities for reinvention — all while upholding safety and sustainability standards.

At Deepwear, we help brands stay ahead of these challenges through AQL batch inspections, responsible waste management, and collaborative recovery solutions. Whether you’ve had a rough experience with another supplier or simply want a more transparent partnership, our team ensures your production stays consistent — and your brand story stays strong.

Ready to recover your denim production and turn defects into design opportunities?

Book a strategy session with Deepwear’s denim consultants or explore our sustainable wash and inspection services today.