Why Bali is Not the Ideal Destination for Garment Manufacturing:

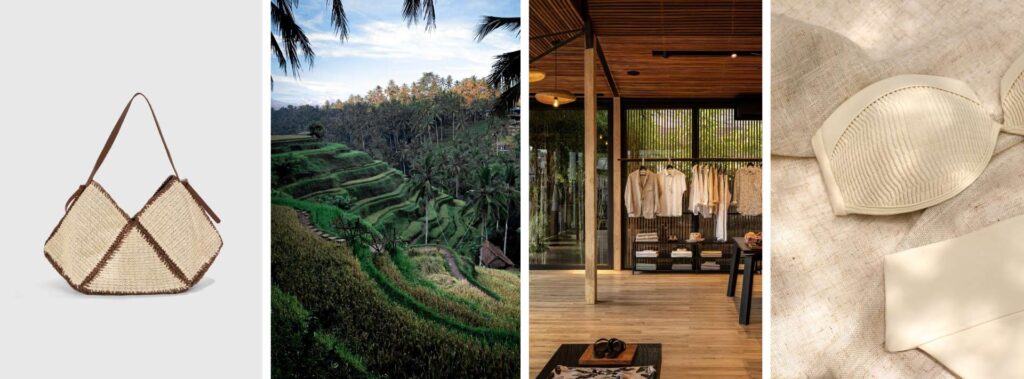

Bali is an icon of the creative imagination. For decades, it has been the ultimate siren song for fashion entrepreneurs—a lush, tropical paradise where “Ubud yoga poses” and “bohemian chic” suggest a world where business and bliss coexist.

But as the messages from our team on the ground reveal: there is a massive, expensive difference between a creative “spot” and a production “structure.” If you are a fashion brand looking to scale, you need to hear the candid truth that Instagram filters hide.

In this blog we cover:

- Why Bali’s creative image doesn’t translate into scalable manufacturing

- Infrastructure, logistics, and quality control risks brands overlook

- Common factory, middleman, and production traps targeting startups

- Environmental and ethical challenges tied to island-based production

- When Bali work and why most brands are better manufacturing elsewhere

Challenges in Bali’s Infrastructure for Manufacturing

Bali’s manufacturing sector faces considerable challenges, particularly in waste management, due to outdated infrastructure and insufficient recycling capabilities.

The “Experience” vs. The “Excellence”

Bali was a great spot 40 years ago when it was a niche hub for artisanal “hippie” crafts. Today, it attracts dreamers without experience who mistake a creative “vibe” for an industrial “structure.”

- Micro-scale only: Bali is a wonderful place to make 30 bikinis for a hobby project. It is a fantastic place for a photoshoot, with world-class photographers and models available at every price point.

- Infrastructure Gaps: Frequent electricity fluctuations and inconsistent internet aren’t just minor inconveniences; they are production killers.

- Logistics & Customs Hell: Bali is an island, not a manufacturing hub. Importing high-quality fabrics, technical trims, or specialized hardware is a nightmare. You will face a labyrinth of customs delays and high duties for a logistics chain simply not designed for the global fashion calendar.

The Cultural Gap & Lack of Industry Education

Fashion is an industry of precision. In established hubs like Portugal or Vietnam, “1cm” is a law. In Bali, the working culture and lack of technical education create a different reality.

- “Island Time” vs. Global Deadlines: Bali’s culture is deeply rooted in community and religious festivals. While beautiful, these ceremonies frequently halt production for days or weeks. Without a professional industrial mindset, your “urgent” delivery is often secondary to local traditions.

- No Technical Backbone: The island lacks formal textile engineering and fashion management institutions. You aren’t working with industrial experts; you are often working with “creatives” who lack the technical knowledge of pattern grading, fabric shrinkage, or international quality control standards.

The “Organized Factory” Trap

- This is the most dangerous part of the Bali mirage. You will find facilities that look like organized factories. They have sleek websites and professional-looking reception areas. These are often traps specifically designed for inexperienced startup brands.

- They project an image of Western efficiency to secure your deposit, but once the money is wired, the “industrial” facade crumbles. You quickly realize they lack the internal systems, the skilled labor, and the quality management to deliver a collection that meets international retail standards.

The Predator Environment: Scams & Advantage-Taking

Bali has become a breeding ground for scams targeting “fashion tourist” brands.

- The Expat “Middleman” Trap: You will find countless foreigners who have lived in Bali for two years and suddenly call themselves “production consultants.” They often have no background in fashion; they simply act as overpriced bridges to local workshops, taking a massive cut while providing zero quality oversight.

- The Advantage-Takers: Local workshops and “fixers” often see new arrivals as “short-term ATMs.” They quote low to get your deposit, then disappear or prioritize other clients, knowing you have little legal recourse on the island.

Who Actually Succeeds in Bali? (The Exception, Not the Rule)

There are brands that succeed in Bali, but they are the 1%. Names like Balizen, Magali Pascal or SukkhaCitta didn’t do it via email from London or New York.

Their success is built on a specific, high-commitment model:

- They Live There: They have been on the island for a long time.

- They Own the Floor: They don’t outsource to “factories”—they have their own workshops.

- Total Presence: They are there every single day, physically supervising every stitch.

- Local Retail: They have their own retail stores on the island to move inventory.

Unless you are prepared to move to Bali, build your own building, and manage a local workforce 24/7, their success story is not a blueprint you can easily follow.

Over-Saturation of Bali’s Market

Bali’s fashion market is becoming oversaturated as emerging brands flock to the island, attracted by perceived low production costs, but this trend often leads to unsustainable practices.

- An Influx of Emerging Fashion Brands Seeking Low Costs

Bali’s allure as a “creative hub” for small and emerging fashion brands has led to market saturation. Many inexperienced brands are drawn by perceptions of affordability, yet the influx has overwhelmed the island’s limited production capacity. The intense competition often drives brands to cut corners, compromising quality, ethical standards, and sustainability in pursuit of lower costs. - Poorly Researched Ventures Leading to Unsustainable Practices

A significant portion of brands entering Bali fail to conduct adequate market research, resulting in ventures that lack long-term viability. Factories are often established without consideration for environmental impacts or efficient processes. This “boom” in demand for low-cost production has created a culture of unsustainable manufacturing, where short-term profits take precedence over quality and ethical practices. - Tourist-Focused Businesses Fueling Environmental Impact

The rise of businesses targeting Bali’s tourist-driven economy has further complicated the landscape. These ventures often prioritize aesthetics over durability, creating products aimed at transient tourist markets or social media trends. While visually appealing, these items frequently lack longevity and quickly contribute to the growing waste problem. Furthermore, Bali’s economy, traditionally centered on tourism, art, and culture, faces challenges aligning with the demands of industrial-scale fashion production. The emphasis on high-volume output and rapid turnaround times clashes with the island’s cultural and environmental ethos, leading to inefficiencies and potential erosion of local values.

Risks of Manufacturing in Bali

Manufacturing in Bali presents several risks, including hidden costs, dependence on imports, and environmental consequences that undermine the long-term viability of production.

- Hidden Long-Term Costs

While Bali may initially appear cost-effective for manufacturing, inefficiencies in production, high waste output, and environmental harm quickly escalate operational costs. Brands face risks to their financial health and reputation due to these challenges, ultimately offsetting any short-term gains. - Dependence on Imported Raw Materials

Bali lacks local resources for large-scale garment production, forcing brands to source raw materials and accessories from other regions. This dependence increases logistics costs, adding complexity to supply chains and negating perceived affordability. - Environmental Consequences of Manufacturing

Garment manufacturing processes in Bali contribute significantly to environmental pollution. Water-intensive dyeing techniques, improper disposal of chemical-laden fabric scraps, and inadequate wastewater treatment exacerbate the island’s ecological strain. These practices harm local communities, aquatic ecosystems, and Bali’s global reputation as a sustainable destination. - Unethical and Unsustainable Practices

The absence of stringent oversight allows some manufacturers to bypass labor and environmental regulations, resulting in exploitative practices. Workers may face unfair wages and unsafe conditions, while factories operate with little regard for environmental standards. Such practices tarnish Bali’s reputation and highlight the challenges of balancing industrial ambitions with ethical considerations.

The Deepwear “Rescue Office”

At Deepwear, we maintain a presence in Bali that we internally call our “Rescue Office.” We don’t produce there—we salvage brands from there.

Every season, ambitious brands make the mistake of starting “serious” production in Bali, only to find themselves stuck in a cycle of ruined samples and missed seasons. We rescue them. We take the creative soul of your project and move the actual manufacturing to countries like Vietnam, China, or Turkey, which have the structure, education, and infrastructure to actually deliver.

Why does Bali experience textile pollution if most manufacturing happens elsewhere in Indonesia?

Bali is not a textile manufacturing hub, but it sits downstream of Indonesia’s industrial regions. Most textile production occurs in islands like Java, where untreated wastewater, dyes, and microplastics enter river and ocean systems. These pollutants travel via marine currents and eventually accumulate along Bali’s coastlines, making the impact highly visible despite the pollution originating elsewhere.

Why is Bali becoming a testing ground for textile pollution solutions?

Bali is emerging as a positive testing ground for tackling textile pollution. Strong global attention, sustainability-driven brands, and active local initiatives have accelerated the adoption of slow fashion, circular design, low-impact materials, and transparent supply chains. These practical solutions are already showing how cleaner production models can be developed in Bali and scaled across Indonesia’s wider textile industry.

Why does Bali experience textile pollution if most manufacturing happens elsewhere in Indonesia?

Bali is not a textile manufacturing hub, but it sits downstream of Indonesia’s industrial regions. Most textile production occurs in islands like Java, where untreated wastewater, dyes, and microplastics enter river and ocean systems. These pollutants travel via marine currents and eventually accumulate along Bali’s coastlines, making the impact highly visible despite the pollution originating elsewhere.

Why is Bali becoming a testing ground for textile pollution solutions?

Bali is emerging as a positive testing ground for tackling textile pollution. Strong global attention, sustainability-driven brands, and active local initiatives have accelerated the adoption of slow fashion, circular design, low-impact materials, and transparent supply chains. These practical solutions are already showing how cleaner production models can be developed in Bali and scaled across Indonesia’s wider textile industry.

From Creative Fantasy to Manufacturing Reality

Sustainable fashion production is essential for reducing the industry’s environmental footprint, and at Deepwear, we are committed to helping brands make responsible manufacturing choices. By working with manufacturers who prioritize sustainability, we aim to guide the industry toward more ethical and eco-conscious practices.

While Bali may have its appeal, the lack of infrastructure for large-scale, sustainable fashion production makes it an unsustainable option for brands committed to minimizing their environmental impact.

Investing in regions with better infrastructure and sustainability practices is key to ensuring the long-term viability of the fashion industry. Ready to explore other regions for your brand? Schedule a consultation with us.