Learn why accurate measurement charts, grading, and sampling are essential for fashion brands and corporate clients. Deepwear ensures garments fit perfectly, perform well, and bring your design vision to life.

Whether you are a fashion brand preparing your next collection or a corporate client sourcing garments for uniforms, events, or branded merchandise, one truth applies:

Sketches and ideas are not enough.

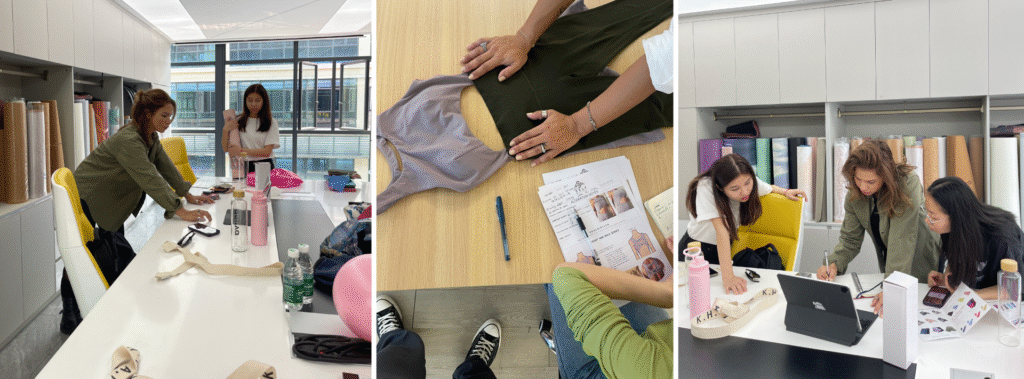

Behind every successful garment lies a careful process of fashion measurement charts, the garment grading process, and apparel sampling solutions. Without these steps, projects risk delays, cost overruns, and disappointing results. At Deepwear, we step in as both your technical partner and your safeguard, ensuring your vision translates seamlessly from concept to production.

In this blog we cover:

- Why fashion measurement charts and tech packs are critical for production.

- The difference between body vs. garment measurements and why it matters.

- How the garment grading process ensures consistent sizing across your collection.

- The role of apparel sampling solutions in protecting your investment.

- Real-world case studies showing how Deepwear safeguards quality.

- How Deepwear production consulting supports both fashion brands and corporate clients.

Why Measurement Charts and Tech Packs Matter

A tech pack and measurement chart form the blueprint of production. They determine how factories interpret your design and calculate everything from fabric usage to cost.

- Fashion brands often arrive with sketches, brand concepts, or rough specifications.

- Corporate clients, however, may know only how they want the garment to look, but not the fabric interactions, ink limitations, or size placement details.

This is where mistakes often happen and where Deepwear adds value. We clarify technical details, bridge creative vision with practical production, and make sure everyone—the client and the factory—understands exactly what’s expected.

Need clarity before you commit to bulk orders? Talk to our sourcing experts.

Body vs. Garment Measurements: The Hidden Trap

A common pitfall for both fashion brands and corporate clients is assuming body measurements equal garment measurements. They don’t—and misunderstanding this can lead to serious issues: ill-fitting garments, wasted materials, and customer dissatisfaction.

- Body measurements represent the wearer’s actual dimensions—chest, waist, hips, arm length, and other points measured directly from the body.

- Garment measurements are the dimensions of the finished product, which include allowances for movement, comfort, style, and even fabric behavior. Stretchy fabrics, thick knits, and structured weaves all behave differently, so the garment must account for these factors.

For example, a parade vest designed for a 90 cm chest may actually need to be manufactured at 92–95 cm depending on:

- The fabric type (lightweight mesh vs. heavier polyester)

- Intended fit (tight-fitting vs. loose and breathable)

- Design features (placement of logos or prints, layering, or added hardware)

Without this adjustment, clients risk garments that:

- Fit too tightly or restrict movement

- Look smaller than expected due to print or panel placement

- Become uncomfortable in real-world conditions, such as a hot outdoor event

At Deepwear, we can see to it that every garment is developed with the right balance between comfort, aesthetics, and wearability. We translate abstract design ideas into concrete specifications that factories can execute, reducing costly errors before production even begins.

Case Study 1: Corporate Parade Vests

One corporate client needed neon parade vests with a multi-ink logo design. Their main priorities were:

- The vest should be eye-catching but remain breathable for hot climates.

- The ink colors must work with the chosen fabric.

- The design needed correct placement and proportion relative to the vest size.

The challenge: the tech pack they provided was incomplete—no fabric selection, no clear logo scale, and limited guidance on how the garment should fit in action.

Deepwear stepped in to:

- Advise on fabric blends suitable for heat management and ink adherence.

- Adjust the ink application so it was durable without compromising airflow.

- Clarify design placement and size scaling before creating the first samples.

The outcome: the samples were delivered on time, looked vibrant, and were comfortable for long outdoor use. By bridging the knowledge gap between concept and production, Deepwear ensured a successful final product.

The Grading Process: Scaling Without Distortion

Once a base size is confirmed (often Medium), garments must be graded across the full size range. Grading ensures every size is proportional and comfortable, but it’s a technical process that goes far beyond simple arithmetic.

Key considerations include:

- Non-linear growth – different areas expand at different rates (e.g., bust vs. length).

- Sizing standards (US, EU, Asia) – each region uses different increments.

- Garment type – hoodies, trousers, children’s wear, or structured jackets each require unique grading logic.

- Fabric behavior – stretch, drape, and shrinkage impact grading decisions.

We consult with suppliers, confirm regional standards, and adjust for fit and fabric behavior so garments are consistent and functional across all sizes.

Case Study 2: Hoodie Samples for a Fashion Brand

A fashion brand we supported designed a multi-ink hoodie. Their artwork was flawless, but during sampling, we noticed a critical issue: the pockets were shallower than the specification.

Without careful oversight, this could have resulted in hundreds of hoodies that failed quality checks or dissatisfied customers.

Instead, Deepwear:

- Flagged the issue early.

- Worked with the factory to adjust pocket depth for the next sample round.

- Ensured the final bulk production matched the approved sample.

This is how we act as bodyguards for your brand, monitoring every detail, spotting potential errors, and keeping production aligned with your expectations.

Ready to develop your first samples with confidence? Partner with Deepwear’s manufacturing team.

Why Sampling and Adjustments Are Non-Negotiable

Whether you’re a corporate client or a fashion brand, sampling is where vision becomes reality.

- First samples test feasibility: does the design work with the chosen fabric, construction methods, and intended fit?

- Adjustments refine the garment: correcting fit issues, resizing graphics, or repositioning features like pockets or logos.

- Factory alignment ensures both client and production team agree on the final product before bulk production.

Multiple rounds of sampling are not failures—they are insurance. They protect your investment, ensuring bulk production delivers exactly what was approved.

How Does Deepwear Ensure Your Garments Turn Out Right?

Whether you’re a fashion brand or corporate client, here’s how we address the most common concerns:

- Multiple sample rounds: Allow adjustments for fit, comfort, and feasibility, ensuring bulk production matches your vision.

- Incomplete tech packs: We clarify fabrics, ink, design placement, and sizing, reducing errors and delays.

- Body vs. garment measurements: We ensure garments fit correctly while maintaining design intent.

- Production oversight: From tech pack review to pre-production, we monitor every stage to catch issues early.

- Corporate clients with little apparel experience: We bridge the technical knowledge gap, saving time and avoiding mistakes.

- Supporting brands and corporates: Our process adapts to all clients, ensuring garments are production-ready, comfortable, and true to design.

What Is the Garment Grading Process in Fashion Production?

The garment grading process is scaling a base size across different sizes while maintaining fit, proportion, and comfort. It considers sizing standards (US, EU, Asia), fabric behavior, and garment type. Deepwear production consulting supports fashion brands with accurate grading to prevent distortion and ensure consistency.

Conclusion

Behind every successful garment is a solid foundation of measurements, grading, and sampling. Deepwear acts as your technical partner and safeguard, ensuring your designs—whether for fashion collections or corporate merchandise—are realized with precision, quality, and efficiency. From first sketch to bulk production, we protect your investment, manage technical challenges, and deliver garments that fit, perform, and impress.

Ready to build your fashion collection on a solid foundation? Book a strategy call with Deepwear’s production experts or explore our full measurement, grading, and sampling solutions today.