The COVID-19 pandemic feels like a distant memory now, five years on. But for Deepwear, it was one of the most defining periods in our history. As a fashion agency with established offices in key manufacturing hubs worldwide, we witnessed firsthand the widespread disruptions that forced brands to rethink their sourcing strategies. Trade wars, raw material shortages, and logistics breakdowns shook the industry, but those who adapted came out stronger.

We don’t give away our expertise for free, of course, but here are some insights on how brands can stay ahead and avoid major supply chain pitfalls.

Lessons from COVID-19 and Trade Wars

The pandemic and ongoing trade disputes exposed weaknesses in global supply chains. Brands that once prioritized cost efficiency over resilience had to rethink their sourcing strategies overnight. The industry’s most critical takeaways remain just as relevant today.

- Overreliance on a Single Market Is Risky

For years, China dominated fashion manufacturing, offering a combination of affordability, infrastructure, and production capacity. However, when China’s lockdowns halted production, brands that relied solely on Chinese factories faced severe delays. Meanwhile, those with diversified sourcing—leveraging Vietnam, India, and Thailand—were able to maintain operations with fewer disruptions.

Beyond pandemic-related risks, geopolitical tensions and tariff fluctuations have further reinforced the need for diversification. Trade wars, particularly between the U.S. and China, have led to higher production costs and unpredictable supply chain disruptions. The lesson is clear: brands that distribute manufacturing across multiple regions are better positioned to weather global uncertainties.

- Just-in-Time Production Isn’t Always the Best Bet

Just-in-time (JIT) production, designed to minimize inventory costs by producing goods only as needed, backfired for many brands during the pandemic. Shipping delays, raw material shortages, and factory shutdowns left companies unable to restock products quickly, resulting in lost sales and weakened customer trust.

Many fashion brands have since shifted toward a hybrid model, balancing JIT efficiency with buffer inventory and nearshoring solutions. By keeping critical stock closer to key markets, brands can reduce lead times while still maintaining cost-effective production strategies.

- Supply Chain Transparency Matters

The pandemic also exposed how little control some brands had over their tiered suppliers. When second- and third-tier suppliers failed to deliver raw materials, many fashion brands were caught off guard, unable to trace where their disruptions originated.

The demand for transparency has since surged, with brands investing in digital tracking solutions such as blockchain, RFID technology, and AI-driven analytics. These tools provide real-time visibility into supplier networks, helping companies make informed decisions and prevent future bottlenecks.

With ethical sourcing and sustainability playing an increasing role in consumer choices, transparency is no longer just about risk mitigation—it’s a competitive advantage.

Strategies for Building a Resilient Supply Chain

To stay ahead, fashion brands must move beyond short-term fixes and develop long-term supply chain resilience. This requires a combination of diversification, technology adoption, strong supplier partnerships, and contingency planning.

- Diversify Manufacturing Locations

Single-source dependency is a high-risk strategy. Instead of relying on one country, brands should establish relationships with manufacturers in multiple low-risk regions.

- Vietnam continues to be a strong alternative to China, offering cost-effective production and skilled labor.

- Thailand and India provide specialized craftsmanship and shorter lead times for niche product categories.

- Nearshoring in Eastern Europe and Turkey helps brands minimize dependence on long-distance supply chains, reducing transit times and geopolitical risks.

A diversified sourcing strategy ensures production continuity, even when unexpected disruptions occur.

- Invest in Technology

Predictive analytics and digital tools are transforming the way fashion brands manage their supply chains. Investing in AI-powered demand forecasting can help brands avoid overproduction while ensuring they have enough stock to meet customer demand.

Meanwhile, digital supply chain management platforms allow brands to track real-time inventory, monitor supplier performance, and quickly adjust sourcing strategies when disruptions arise. 3D design and virtual sampling also reduce development timelines, making production more agile and cost-effective.

- Strengthen Supplier Relationships

Building long-term, trust-based relationships with suppliers is essential for maintaining production stability. Rather than jumping from one manufacturer to another based on short-term cost savings, brands should prioritize suppliers that offer:

- Ethical and sustainable manufacturing practices

- Reliable quality and on-time delivery

- A willingness to collaborate on innovation and efficiency improvements

- Strong supplier relationships ensure that when crises hit, brands have partners who are willing to be flexible and supportive.

- Plan for Logistics Contingencies

Logistics failures were one of the biggest disruptions during the pandemic, with port congestion, freight cost spikes, and transportation bottlenecks delaying shipments worldwide. Brands that lacked alternative logistics plans suffered the most.

A robust contingency strategy includes:

- Diversifying shipping routes to avoid over-reliance on a single port or carrier

- Exploring alternative transport options, such as air freight, for urgent orders

- Establishing regional distribution centers to keep inventory closer to customers

- Proactive logistics planning can significantly reduce lead time disruptions and ensure business continuity even when global transport systems are under stress.

How Deepwear Helps Brands Mitigate Supply Chain Risks

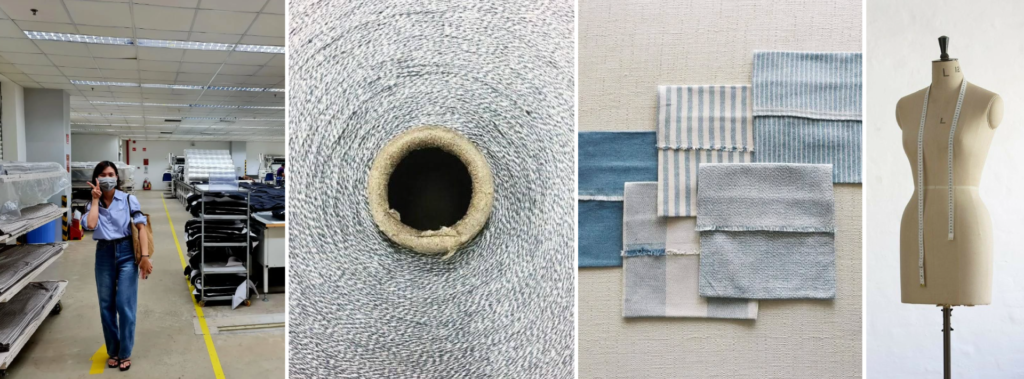

At Deepwear, we specialize in helping fashion brands build agile, ethical, and future-proof supply chains. Our expertise in global sourcing, compliance, and risk management ensures that our clients stay ahead of disruptions.

- Global Sourcing Expertise

With offices in key manufacturing hubs worldwide, we provide diversified sourcing options that reduce risk and increase flexibility. Whether brands need high-volume production or specialized craftsmanship, our global network ensures they have access to the best suppliers.

- Quality Assurance & Compliance

Maintaining consistent product quality and ensuring compliance with labor and environmental standards is non-negotiable. Deepwear conducts thorough supplier audits, on-site inspections, and quality control checks to guarantee that products meet international standards.

We help brands avoid costly reworks, non-compliance penalties, and ethical sourcing pitfalls by maintaining strict oversight of production processes.

- Agile Supply Chain Solutions

Disruptions are inevitable, but with the right strategies in place, brands can respond quickly and minimize impact. Deepwear’s expertise in crisis management and strategic planning helps brands:

- Identify potential risks before they escalate

- Develop alternative sourcing strategies

- Implement real-time supply chain monitoring for better decision-making

The Future of Fashion Supply Chains

In an industry where uncertainty is the only constant, fashion brands must rethink how they approach sourcing, production, and logistics. Those that embrace diversification, technology, transparency, and strong supplier relationships will be the ones that thrive.

Supply chain disruptions will continue to test the industry, but with proactive planning and the right partners, brands can stay resilient, competitive, and prepared for whatever comes next.

At Deepwear, we help brands turn challenges into opportunities—because in fashion, staying ahead is everything.

Ready to take the next step? Schedule a consultation with us today.