Discover coconut-based textiles—coir, charcoal fabrics, and vegan leather. Learn how fashion brands can source sustainable fabrics with Deepwear’s experts.

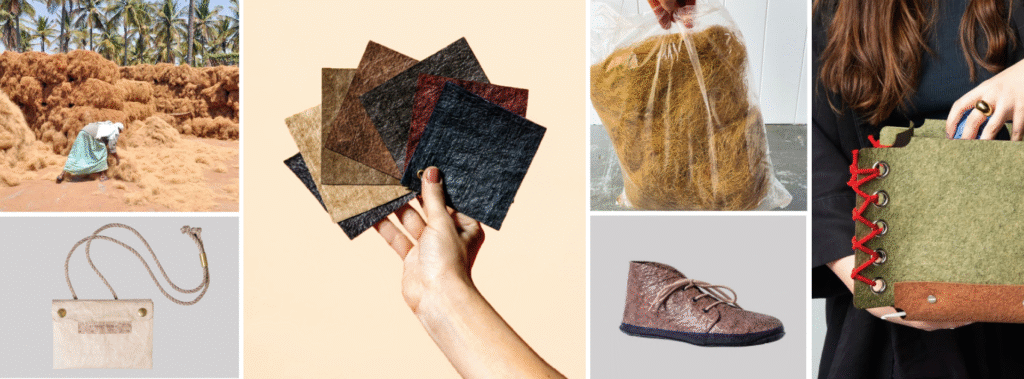

Coconut is often called the “tree of life” because nearly every part of it is useful—and constant scientific research has shown that this miracle tree can also inspire coconut textile innovation. Today, what’s marketed as “coconut fabric” actually refers to three distinct material families: biodegradable coir fibers, coconut-charcoal fabrics, and vegan coconut leather. Each has unique properties, applications, and sustainability considerations.

In this guide, we’ll help brands understand how coconut fabrics are made, their unique strengths, and what to consider when sourcing them. Specifically, we cover:

- What coconut fabric is and how it differs across material types.

- Sourcing, pricing, and lead times for coir, coconut-charcoal textiles, and coconut leather.

- Production methods and key properties for each material.

- How Deepwear’s sourcing experts can support brands with testing, quality control, and sample development.

- Sustainability considerations and practical advice for integrating these materials into collections.

What is Coconut Fabric?

When brands refer to coconut fabric, they are usually talking about one of three distinct materials. Each has unique properties, applications, sourcing considerations, and price points, so understanding the differences is key to making informed decisions:

Coir (Coconut Husk Fiber)

- What it is: A coarse, durable fiber extracted from the coconut husk, used in mats, ropes, fillings, and geotextiles. Renewable and biodegradable, but not suitable for soft apparel without heavy processing or blending.

- Sourcing countries: India, Sri Lanka, Vietnam, Philippines. Deepwear primarily sources from India and Vietnam.

- Estimated price range: $3–$8 per kg for raw fiber; $5–$15 per kg for processed yarns or mats, depending on quality and blend.

- MOQ / Lead time: Typically 500–1,000 kg; 4–8 weeks production.

- Typical use-cases: Mats, rugs, ropes, geotextiles, mattress or cushion fillings.

Coconut-Charcoal Textiles

- What it is: Fabrics incorporating activated carbon from coconut shells to improve odor control, moisture management, and thermal comfort.

- Sourcing countries: Indonesia (shells), India, Vietnam. Deepwear focuses on India and Vietnam.

- Estimated price range: $8–$20 per meter for finished fabrics.

- MOQ / Lead time: Typically 200–500 meters; 6–10 weeks production.

- Typical use-cases: Activewear, socks, underwear, bedding, mattress covers.

Coconut-Based “Leather” (Biocomposites)

- What it is: Made by cultivating bacterial cellulose on coconut-processing byproducts and finishing into eco-friendly leather alternatives. Best for small accessories or light footwear, not apparel.

- Sourcing countries: India, Philippines, Sri Lanka. Deepwear sources primarily from India and Vietnam.

- Estimated price range: $25–$60 per square meter, depending on thickness, finishing, and certifications.

- MOQ / Lead time: Typically 50–200 sheets; 8–12 weeks production.

- Typical use-cases: Bags, wallets, small footwear, decorative accessories.

We maintain sourcing offices in India, Vietnam, Thailand, and China, enabling production oversight and quality monitoring. Our Bali, Indonesia office primarily supports clients who have faced sourcing issues rather than acting as a production hub.

Price disclaimer: Prices are indicative of typical market ranges as of 2025. Actual costs may vary by supplier, order volume, processing, and regional factors. Always request formal quotations for accurate budgeting.

Coconut fabrics are part of a broader movement toward sustainable natural fibers. For more context on eco-friendly textiles, see our previous blog: 10 Best Eco-Friendly Natural Fabrics of 2025 for Sustainable Fashion, which includes coir alongside other renewable materials.

Exploring How Coconut Fabrics Can Be Made and Used

After understanding what coconut fabric is, it’s helpful to look deeper into how each material can be produced, what properties they can offer, and how brands can work with them effectively. The following sections break down coir, coconut-charcoal textiles, and coconut-based leather, highlighting production insights, performance characteristics, and how Deepwear can support sourcing, testing, and quality management.

How Can Coir Be Extracted and Used?

- Retting, washing, drying, and spinning processes turn husks into yarns.

- Deepwear’s sourcing experts can oversee quality and traceability.

- Properties include stiffness, high lignin content, and salt resistance.

- Applications: ropes, mats, geotextiles, fillings.

How Can Coconut-Charcoal Fabrics Enhance Performance?

- Activated carbon from shells is blended into fibers.

- Properties: odor control, antimicrobial effects, thermal comfort.

- Integration: in-polymer blending or topical application.

- Deepwear can guide brands on performance testing and wash durability.

How Can Coconut-Based Leather Be Made and Tested?

- Bacterial cellulose grown on byproducts is finished into vegan coconut leather sheets.

- Pros: renewable, biodegradable, animal-free.

- Cons: lower strength, best for accessories.

- Deepwear can support sustainability testing (GOTS, OCS, RCS).

FAQ

What Are Coconut Fabrics and How Are They Used in Fashion?

Coconut fabrics generally fall into three categories:

- Coir: strong, biodegradable coir fibers ideal for mats, ropes, and interiors.

- Coconut-charcoal fabrics: performance textiles for activewear, socks, and bedding.

- Vegan coconut leather: an eco-friendly leather alternative suitable for accessories and footwear.

These innovations allow brands to combine functionality with sustainability. Deepwear’s sourcing experts can guide brands in testing, sourcing, and integrating coconut textiles into eco-conscious collections.

Conclusion

Coconut fabrics offer brands a unique opportunity to combine sustainable fabric sourcing, performance, and innovation. From coir to charcoal-infused textiles and coconut-based leather, each material serves distinct product needs while reducing environmental impact.

Ready to innovate with coconut-based textiles? Book a strategy session with Deepwear’s sustainable sourcing experts or explore our global coconut fabric partners today.