3D knitting reshapes modern fashion production — reducing inventory risk and enabling on-demand manufacturing, but with real cost and sourcing constraints. Deepwear helps brands evaluate when 3D knitting makes strategic, financial, and technical sense.

3D knitting is often framed as a breakthrough technology. In practice, its significance lies elsewhere: it reshapes how brands think about production risk, flexibility, and scale.

At a time when overproduction, long lead times, and inventory write-offs are no longer acceptable costs of doing business, 3D knitting offers a different production logic — one that prioritizes digital control, material precision, and on-demand output. But this logic comes with real constraints. Understanding those constraints is essential before adopting the technology.

In this blog we cover:

- What 3D knitting actually is and how it works in real production

- Why 3D knitting functions as a production logic, not just a technology

- How it supports on-demand manufacturing and lower inventory risk

- The cost realities brands must account for, from machines to materials

- MOQ and pricing signals across key global sourcing regions

- How Deepwear evaluates when 3D knitting makes strategic sense for brands

What is 3D Knitting?

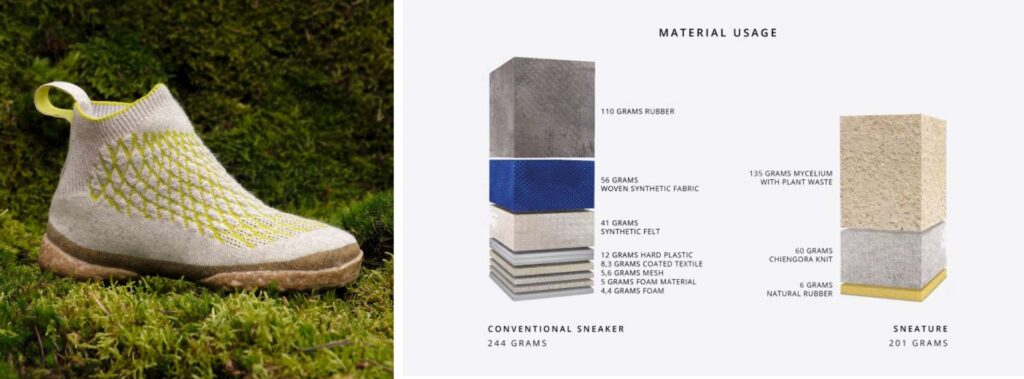

3D knitting refers to a digital, computerized manufacturing process in which products are knitted directly into their final three-dimensional form from yarn, without cutting or sewing. Designs are created digitally and executed by advanced knitting machines that control stitch structure, density, and material placement with high precision.

Unlike traditional knitting, which produces flat panels that must be assembled later, 3D knitting builds the form itself during production. This makes it closer in logic to additive manufacturing: digital input → physical output, with minimal intermediate steps.

Key characteristics:

- Seamless or near-seamless construction

- Digitally programmed production

- Precise material usage with minimal waste

- Easy size or structure adjustments without retooling

Importantly, knitting itself is inherently three-dimensional. It requires spatial thinking, structural planning, and material behavior awareness — qualities that make it one of the most literal forms of “soft” 3D fabrication.

Beyond Garments: A Scalable Fabrication Logic

3D knitting is best understood not as a trend, but as a production logic. While apparel remains the most visible output, the real value lies in how digitally programmed knitting restructures the way products are designed, manufactured, and scaled.

Unlike traditional cut-and-sew workflows, 3D knitting allows form, function, and material behavior to be resolved at the machine level. This has implications not only for garments, but for any product category where fit, efficiency, and material intelligence matter.

From a manufacturing perspective, this approach enables:

- Single-piece construction with reduced assembly steps

By producing three-dimensional forms directly from yarn, brands can reduce labor, seams, and post-production handling.

- Early design decisions that carry through production

Because patterns, structure, and performance zones are digitally programmed, design intent is preserved more consistently from prototype to bulk.

- Material efficiency and waste control

Yarn is used precisely where needed, supporting tighter yield management—particularly relevant for premium or technical fibers.

- Flexible scaling across product categories

The same knitting logic can be applied to apparel, soft furnishings, technical textiles, and emerging hybrid products.

Research from the MIT Media Lab reinforces why this matters commercially. Their work demonstrates how digitally controlled knitting can integrate functional yarns directly into three-dimensional textile structures, producing seamless, body-conforming surfaces capable of sensing pressure, movement, and biomechanical activity. These textiles are shaped and personalized through knitting and thermoforming, rather than through external attachments or layered construction.

For brands, the takeaway is not the technology itself, but the principle it proves:

- Function can be designed into the structure of the textile, rather than added later.

- Complex performance outcomes can be achieved without complex assemblies.

- Digital design and manufacturing are directly linked, reducing translation loss between concept and production.

While these MIT systems are not commercial products, they validate a direction the industry is already moving toward—one where textiles shift from passive materials to programmable surfaces. This has direct relevance for performance wear, medical and wellness products, and future-facing lifestyle categories.

For Deepwear clients, this reinforces a core manufacturing reality:

3D knitting is not just about what you make—it’s about how early design decisions influence cost, scalability, and feasibility. When used strategically, it offers brands a way to rethink production architecture, not just product aesthetics.

Cost Reality: What Brands Need to Understand

Seen from the outside, 3D knitting is often framed as an efficiency play. In practice, it is better understood as a precision and risk-management method, not a low-cost shortcut. Brands considering this production route need to understand where costs concentrate and why.

1. Machine Investment Is High

Advanced 3D knitting machines are capital-intensive, often costing hundreds of thousands of dollars per unit. This naturally limits access and concentrates production within specialized factories that can justify long-term utilization.

For brands, this means supplier choice matters more than ever—capacity, machine mix, and technical depth directly affect feasibility.

2. Programming Skills Are Scarce

Unlike conventional knitting, 3D knitting relies heavily on highly skilled knit programmers who understand yarn behavior, stitch topology, and machine logic simultaneously.

This expertise is limited globally. It adds cost, extends development timelines, and makes early-stage collaboration essential rather than optional.

3. Costs Are Front-Loaded

3D knitting reduces sewing and assembly labor, but replaces it with digital setup, programming, and calibration. In other words, cost does not disappear—it shifts forward.

Sampling, testing, and iteration require more upfront investment, even if bulk production becomes cleaner and more predictable later.

4. Yarn Becomes the Main Cost Driver

With minimal waste and fewer opportunities to mask inefficiencies, yarn quality becomes non-negotiable. Fiber choice directly affects performance, durability, and unit economics.

Advanced or functional yarns raise costs, but they also define the product’s value proposition making material strategy central, not secondary.

3D knitting often increases per-unit production cost, but it reduces systemic risk—fewer errors, fewer unsold units, and fewer forced markdowns. For the right product, this trade-off is intentional.

If your team is exploring whether 3D knitting is the right production route, our consultants can review your product brief, budget, and timelines to assess feasibility before you commit to sampling or machinery-dependent workflows. Speak with Deepwear’s production advisors through our contact page to map realistic next steps.

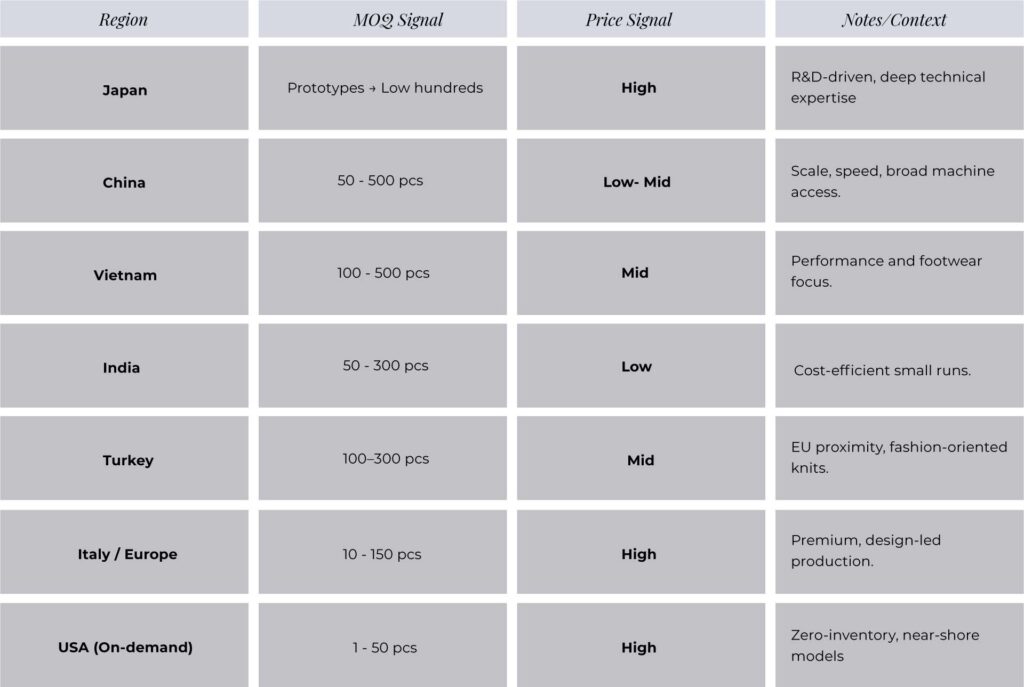

MOQ & Pricing Signals by Region

Disclaimer: Because 3D knitting is machine- and skill-dependent, minimum order quantities and pricing vary significantly by region. The table below reflects market signals, not guarantees. Actual outcomes depend on product complexity, yarn choice, and machine availability.

These MOQ and pricing signals are used as strategic indicators, not promises. They help brands understand where experimentation, scaling, or on-demand production is realistically possible.

Is 3D Knitting Cheaper Than Traditional Manufacturing?

Not necessarily. 3D knitting often shifts costs to the beginning of the process — through machine programming, technical development, and higher-grade yarns. While assembly labor and waste may decrease, brands should expect higher upfront sampling and programming investment. The value of 3D knitting lies in precision, lower inventory risk, and better alignment between design and production — not in low-cost manufacturing. Deepwear helps brands evaluate these trade-offs before entering production.

How Deepwear Evaluates 3D Knitting for Brand Production

3D knitting does not replace traditional manufacturing. It redefines where precision matters.

For brands, the value of 3D knitting lies in how it reshapes trade-offs:

- Higher upfront costs in exchange for lower downstream risk

- Digital planning in place of manual correction

- Structural design replacing layered assembly

Used correctly, it allows brands to align design, material choice, and manufacturing constraints earlier in the process where mistakes are cheaper and decisions are more meaningful.

At Deepwear, this is how we approach 3D knitting in practice:

- We evaluate product suitability first, not machine capability

Not every style benefits from 3D knitting. Fit sensitivity, performance requirements, and production scale determine whether the method makes sense.

- We treat MOQ as a signal, not a promise

Regional MOQ ranges help brands choose where to prototype, test, or scale without locking them into unrealistic expectations.

- We align yarn strategy with production reality

Because yarn drives cost and performance, material decisions are made alongside machine and programming considerations, not afterward.

- We position 3D knitting as part of a broader sourcing strategy

It works best when combined with other manufacturing methods, not isolated as a one-size-fits-all solution.

If your brand is considering 3D knitting as part of its production strategy, Deepwear can help you evaluate feasibility, regional sourcing options, and cost implications with clarity. Share your project details with our team, and we’ll help you determine whether 3D knitting is the right path — or whether another manufacturing approach will perform better for your goals.