Understand the difference between trim cards, lab dips, and fabric swatches—and why they are critical to avoid costly mistakes before bulk apparel production. Deepwear helps brands control quality and scale with confidence.

For emerging fashion brands, the jump from design concept to physical product is where most mistakes happen. Not because founders lack creativity, but because apparel production depends on process, precision, and clear communication, especially when working with factories overseas.

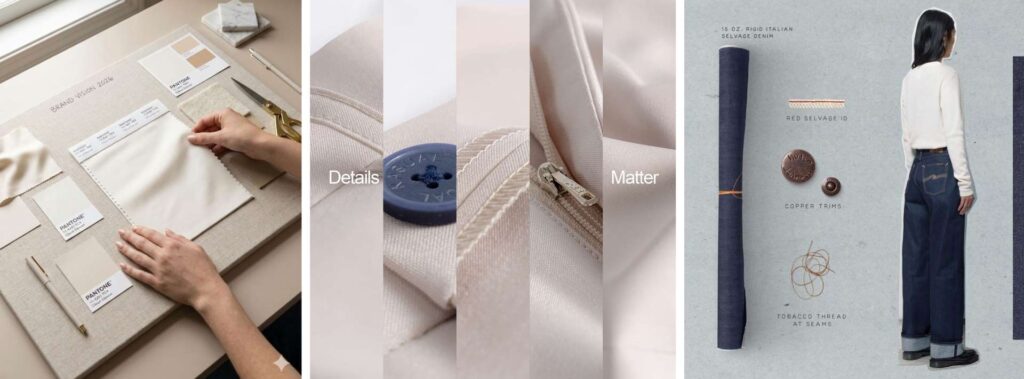

Terms like trim card, lab dip, and swatch often appear during sampling and pre-production, yet many first-time brands don’t fully understand what they are or why they matter. In practice, these tools exist for one simple reason: to make sure what gets produced matches what you approved.

At Deepwear, we see this every day. Brands that understand and use these tools early experience fewer delays, fewer quality issues, and smoother production runs. Brands that skip them often learn the hard way.

In this blog we cover:

- What trim cards, lab dips, and swatches are, and how they differ

- Why physical references matter more than digital mockups in apparel production

- Common mistakes emerging brands make during sampling and pre-production

- How these tools work together in a clear, cost-efficient production flow

- How Deepwear helps brands reduce risk, control costs, and scale with confidence

Why Physical References Matter in Apparel Production

Fashion is tactile. Screenshots, mood boards, and written descriptions can’t fully capture how color, fabric, and components behave in real life.

That’s why apparel manufacturing relies on physical approval tools to remove interpretation and replace it with clarity. For emerging brands, this usually comes down to three essentials:

1. Trim Cards

A trim card is a reference sheet that holds actual samples of all non-fabric components used in a garment. This typically includes:

- Buttons and snaps

- Zippers and pulls

- Threads

- Labels (neck, care, size)

- Drawcords, elastics, toggles, and hardware

Suppose you’re producing a zip-up hoodie. You’ve chosen a matte black zipper instead of a glossy one, a thicker drawcord for a premium feel, metal eyelets rather than plastic, and a woven neck label instead of a printed one. Individually, these decisions feel minor. Together, they define how your garment looks, feels, and positions itself in the market.

A trim card brings all of these elements into one clear, physical reference. Without a trim card, factories may substitute components that are “close enough.” A zipper might be the same size but a different finish. A label might be printed instead of woven. A thread color might be slightly off. None of these changes are dramatic on their own, but collectively, they alter the product you worked hard to design.

For emerging brands, trim cards act as a safeguard:

- They ensure consistency across production

- They serve as a quality control reference

- They give factories clear, non-negotiable instructions

Deepwear has covered the importance of trims in our articles on labels and trims and the role of trims in garment design. Trim cards are where that knowledge becomes operational.

2. Lab Dips

A lab dip is a small fabric swatch dyed to match a specific color standard, usually based on a Pantone reference or buyer-provided sample. It allows brands to approve color accuracy before large-scale dyeing.

Color is one of the most misunderstood aspects of apparel production. A shade that looks perfect on a digital mockup can shift dramatically once applied to fabric. Lighting, fiber content, weave, and dye method all affect the final result.

Suppose you’re producing a t-shirt in what you describe as “sage green.” The dye house sends several dyed swatches. One leans yellow, another looks grey, another finally matches what you imagined. Each of these is a lab dip. Only one should be approved.

Approving a lab dip means you’re approving:

- The exact shade

- The dye formulation

- The reference for bulk production

Skipping lab dips is one of the most expensive mistakes emerging brands make. Once bulk fabric is dyed, correcting color issues becomes time-consuming and costly—and in some cases, fabric must be discarded entirely.

From a sustainability and cost-control perspective, lab dips reduce waste and protect margins.

3. Swatches

A swatch is a small fabric sample used to assess material quality, texture, weight, and finish. While lab dips focus on color, swatches answer a different question: does this fabric feel right?

Two fabrics can share the same technical specifications—100% cotton, 180 GSM—and still behave very differently in real life. One may feel soft and breathable, the other stiff and flat. One may drape well, the other may hold awkwardly on the body. For this reason, we recommend requesting A4-sized swatches, as they provide enough surface area to accurately assess drape, hand feel, structure, and overall fabric performance rather than relying on small cuttings.

Swatches allow brands to make informed decisions before committing to production. They’re also used to test:

- Print quality and color clarity

- Embroidery or embellishments

- Washes and surface finishes

In printed designs, a swatch may take the form of a strike-off, confirming how artwork translates onto fabric. However, it’s important to note that a lab dip is a type of swatch, but not all swatches are lab dips. Some are undyed fabric trials, others are yarn-dyed samples or woven tests. Together, they give brands a complete picture of what they’re about to produce.

This hands-on evaluation is central to the sampling process we outline in our garment sampling guide, where material decisions are treated as foundational, not cosmetic.

Not sure if your trim cards, lab dips, or swatches are ready for bulk production? Talk to Deepwear’s production team to review approvals, flag risks early, and avoid costly mistakes before manufacturing begins.

How Trim Cards, Lab Dips, and Swatches Work Together

While trim cards, lab dips, and swatches serve different purposes, they’re most effective when used together as part of a clear pre-production sequence. Each tool answers a different question, and skipping one often creates problems later.

In practice, the flow looks like this:

- Swatches come first, helping brands confirm how a fabric actually feels, drapes, and performs beyond what a spec sheet can show.

- Lab dips follow, once the fabric is selected, locking in the exact color on that specific material before bulk dyeing begins.

- Trim cards come last, bringing together all approved components so fabric, color, and trims work cohesively as a finished product.

Only after all three are approved should bulk production begin.

This sequence matters because apparel production compounds decisions. A color approved on the wrong fabric, or trims selected before color is finalized, can create mismatches that are difficult to correct later.

When used correctly, these tools:

- Reduce miscommunication between brands and factories

- Speed up approvals by providing clear physical references

- Create a shared standard for production and quality control

When working with overseas suppliers, this clarity is especially important. Physical references remove assumptions, align expectations, and make production more predictable.

What Is the Difference Between a Trim Card, Lab Dip, and Fabric Swatch?

A trim card groups all non-fabric components used in a garment, such as buttons, zippers, and labels, to ensure consistency during production. A lab dip is a dyed fabric sample approved to lock in exact color before bulk dyeing. A fabric swatch allows brands to assess texture, weight, and performance. Together, these tools prevent miscommunication, quality issues, and costly production errors. Deepwear helps brands manage and approve each step before scaling.

How Deepwear Helps Emerging Brands Avoid Costly Mistakes

For emerging brands, the biggest production risks are rarely creative; they’re financial. Color errors, trim substitutions, and material mismatches often surface only after bulk production begins, when fixes are slow, expensive, and disruptive.

At Deepwear, we help brands get swatches, lab dips, and trim cards right before scale, so approvals happen while changes are still affordable. This reduces uncertainty and protects both timelines and cash flow.

Our process can helps brands:

- Lock color accuracy before bulk dyeing begins

- Prevent trim substitutions and component inconsistencies

- Reduce reorders, re-dyeing, and delayed launches

- Create clear references for factories and quality control

In apparel production, prevention costs less than correction. For brands working with tight budgets, that difference can determine whether a collection ships smoothly or stalls mid-production.

The takeaway? clarity before scale protects your product, your timeline, and your margins.

Ready to Produce With Confidence?

Scaling a collection shouldn’t come with avoidable risks. Deepwear supports emerging and growing brands with hands-on production guidance—from sampling approvals to factory coordination—so your first bulk run matches exactly what you approved.

Get in touch to align your production process before you scale.