Learn how fashion brands can control fabric shrinkage through testing, sourcing, and expert inspections with Deepwear’s global textile team.

Shrinkage is often misunderstood as a simple laundry mishap—but for fashion brands, it’s a product integrity risk that affects fit, longevity, and customer trust. While consumers may blame improper care, the root cause often lies earlier in the supply chain.

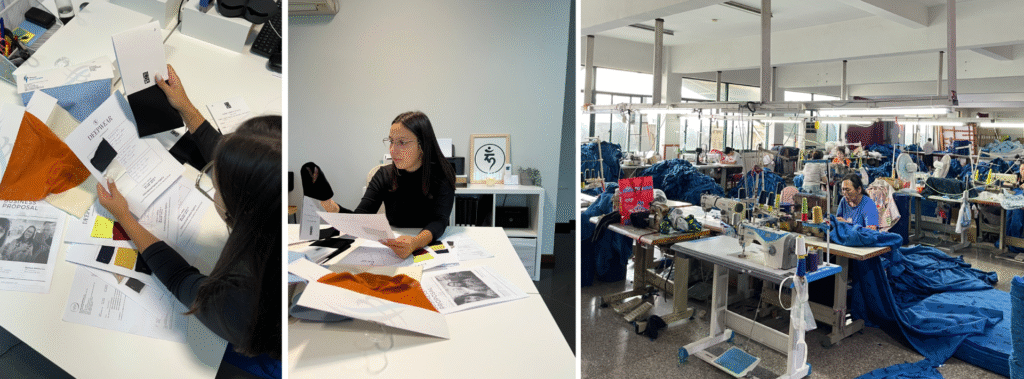

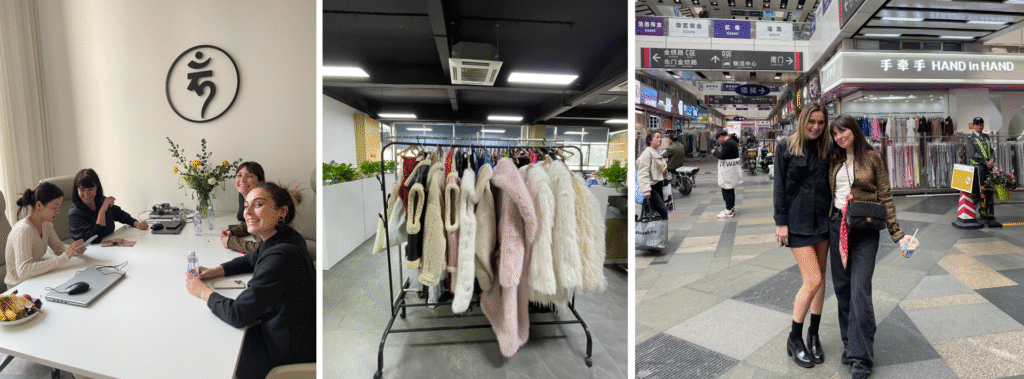

At Deepwear, we help brands manage shrinkage from the fabric roll to final garment inspection through expert sourcing, standardized testing, and precise production oversight.

In this blog, we’ll cover:

- What causes fabric shrinkage

- The different types of shrinkage and how they behave

- How laundering contributes to fabric distortion

- How to test and control shrinkage across materials

- Why designer garments require extra caution

- Strategies for managing shrinkage during production

What is Fabric Shrinkage?

Fabric shrinkage refers to the dimensional change a textile undergoes after washing, drying, or exposure to heat and moisture. This occurs because fibers are stretched under tension during weaving or knitting, and exposure to water, heat, or mechanical action allows them to relax toward their original state.

The Bigger Picture

For fashion brands, uncontrolled shrinkage can lead to poor garment fit, increased product returns, and erosion of customer trust and brand credibility. Even a 2–3% dimensional change can significantly distort a carefully tailored silhouette or render standard sizing unreliable. That’s why shrinkage isn’t simply a post-purchase concern—it’s a production issue that must be anticipated and managed from the first fabric roll.

If you want to learn more about fabric behavior and sourcing strategies in our guide “Natural vs Synthetic? A Sourcing Guide to Misunderstood Fabrics”

What Causes Fabric Shrinkage in 2025 and How Can Fashion Brands Prevent It?

In 2025, shrinkage in fashion production continues to pose a serious risk to garment fit, longevity, and customer satisfaction—especially in designer or technical apparel. Common causes include:

- Relaxation shrinkage from release of fabric tension after weaving/knitting

- Progressive shrinkage from repeated washing

- Felting shrinkage due to moisture, heat, and agitation in animal fibers

Other triggers include improper laundering, excessive heat, harsh detergents, and mechanical stress.

To control shrinkage, Deepwear helps brands apply a multi-step process:

- Fabric shrinkage testing using ISO 6330 or AATCC 135 protocols

- Strategic fabric sourcing for dimensional stability

- Pattern corrections based on lab data

- Real-world simulations and compatibility checks

Whether you’re producing basics or couture, fabric shrinkage control must be built into sourcing, testing, and fit engineering from day one. The result? Fewer returns, better brand trust, and garments that fit as intended.

Types of Shrinkage (and Why They Matter in Sourcing)

Not all shrinkage behaves the same way, and knowing how each type works helps brands make smarter sourcing decisions and avoid costly fit problems. This is why relaxation shrinkage, progressive shrinkage, and felting shrinkage must be factored in early.

1. Relaxation Shrinkage

- This most common form occurs when tension from weaving or knitting is released during the first wash.

- Fibers like cotton, rayon, and woven linen collapse slightly, often shrinking by several percent unless pre-treated.

- That’s why fabrics must be pre-shrunk or sanforized before cutting patterns.

2. Progressive Shrinkage

- Occurs gradually over multiple wash cycles due to fiber swelling and entanglement.

- Common with wool, viscose, and other protein-based or semi-synthetic fibers.

- Special blends or finishes are needed to maintain shape over time.

3. Felting Shrinkage

- Specific to animal hair fibers such as wool.

- Exposure to heat, moisture, and friction causes microscopic fiber scales to interlock irreversibly—leading to felting and irreversible shrinkage.

- Avoiding felting often requires specialized finishes like superwash treatment.

What Really Causes Shrinkage (Beyond Just the Fabric)

While fiber type and fabric construction play a major role, shrinkage is often the result of what happens after the fabric leaves the loom—particularly during washing and drying. Many brands overlook this stage, but it’s where the most damage can occur if not properly accounted for.

Key Shrinkage Triggers in Laundering:

- Incorrect water temperature: Hot water causes fibers—especially natural ones—to contract.

- High heat during drying: Heat exposure can drastically shrink untreated fabrics.

- Mechanical agitation: Harsh movements in washing machines can entangle fibers, especially wool and viscose.

- Fast spin/extraction speeds: Adds mechanical stress, especially in blends.

- Chemical dosing: Harsh or excessive detergents can strip finishes or cause uneven shrinkage.

- Improper rinsing: Residue left behind can continue to affect fabric behavior post-drying.

Even fabrics that have been pre-treated or blended for stability can still shrink if laundered under the wrong conditions. That’s why reliable shrinkage control requires considering not just the fiber—but also the end-use and care instructions.

Why Designer Garments Are Especially at Risk

The more complex a garment is, the less tolerance there is for unexpected dimensional changes. This makes designer and high-end pieces particularly vulnerable.These garments are built with intention. Whether it’s a sculptural silhouette, a fluid drape, or a sharp tailored edge, the final product relies on consistency in fit and proportion. Even a 2% shrinkage variation can throw off alignment between panels, distort embellishments, or affect the flow of the fabric—all of which compromises the original design.

Unlike standard basics, designer pieces often involve:

- A mix of contrasting fabrics in one piece—like structured cotton paired with fluid silk

- Tailored cuts and precision shaping that depend on millimeter accuracy

- Trims, dyes, and surface embellishments that each respond differently to heat, moisture, or agitation

- Stringent aesthetic standards, where visible puckering or asymmetry isn’t just a flaw—it’s a dealbreaker

Care labels may read “dry clean only” or “handle with care,” but the real protection begins much earlier—during fabric testing, patternmaking, and construction. If each material hasn’t been stabilized under realistic conditions, even a well-cut garment can lose its form after the first clean.

In collections where brand value is built on craftsmanship and consistency, a mismatch in shrinkage between fabric panels or lining layers can lead to visible warping, puckering, or outright garment rejection.

That’s why Deepwear prioritizes early-stage testing and cross-fabric prototyping for designer and technical garments. We can help brands catch and correct shrinkage issues before the first piece goes into production—because in luxury fashion, precision is everything.

Deepwear’s Approach to Minimizing Shrinkage Risk

Controlling shrinkage requires more than just selecting the right fabric; it demands a structured, technical approach across sourcing, testing, and sampling. Here’s how Deepwear can support brands in reducing shrinkage-related issues before they reach production.

1. Fabric Selection with Built-In Stability

We can prioritize fabric selection with built-in stability and support pattern corrections to ensure post-wash accuracy. We can also collaborate with mills and textile partners who provide materials tested to meet specific shrinkage tolerances. This allows us to advise on fiber choices and fabric blends that offer better dimensional stability—for example, cotton-polyester over untreated 100% cotton in high-risk styles.

Regional factors such as humidity, laundering practices, and consumer use cases are also considered when helping clients choose the right materials for their target markets.

2. Laboratory Shrinkage Testing (AATCC 135 / ISO 6330)

Before a garment enters sampling, we can run shrinkage tests using AATCC 135 / ISO 6330 protocols:

- A 50 cm × 50 cm square is marked on fabric samples

- Each swatch is washed and dried under controlled conditions

- The percentage of shrinkage is calculated based on dimensional change

This data helps determine whether the fabric is suitable for production and informs necessary pattern adjustments.

3. Pattern Corrections and Sample Adjustments

Using test results, we can work with patternmakers to account for shrinkage at the earliest stage possible. Adjustments are made to pattern dimensions so the final garment matches the original design—after washing.

This step is crucial for tailored cuts, multi-fabric garments, and mass production, where small variances can cause big problems at scale.

4. Technical Support for Complex Garments

For garments with mixed fabrics, surface treatments, or custom dyeing, we can provide compatibility analysis to help brands avoid mismatched shrinkage behavior.

Where needed, we can recommend:

- Fabric-specific finishing

- Garment washing protocols

- Structural reinforcements

These targeted strategies help preserve design intent while minimizing risks like puckering, twisted seams, or felting.

Understanding Shrinkage Tolerances and How to Stay Within Them

Shrinkage is a natural property of textiles, but that doesn’t mean it’s unpredictable. Each fiber type comes with its own expected range of dimensional change—and knowing these benchmarks helps brands set realistic quality parameters and avoid costly rework.

Typical Shrinkage Tolerances by Fiber Type:

- Cotton: 2–4%

- Linen: 3–4%

- Wool: Up to 5%

- Rayon/Viscose: 3–5%

- Polyester: Less than 1%

- Cotton-poly blends: 1–3%

While these figures serve as a general guide, actual results vary depending on construction, finishing, and fabric weight. For example, a loosely woven cotton may shrink more than a tightly woven one, and viscose can behave differently depending on its treatment or dye method.

How to Keep Shrinkage Under Control

At Deepwear, we help brands stay within these tolerances using a layered strategy that includes sourcing, testing, and engineering. But even beyond our support, there are foundational steps every production team should prioritize:

- Choose stable or blended fabrics when long-term dimensional control is essential

- Opt for pre-shrunk, sanforized, or compacted fabrics where possible

- Conduct lab testing early—before bulk ordering or sample cutting

- Factor shrinkage into patterns and grading rules, not as an afterthought

- Educate on care labeling and laundering to ensure that garments perform well post-sale

When properly managed, shrinkage becomes just another spec—not a source of stress. The key is to treat it as a measurable and controllable part of the production process, not a post-launch problem.

Facing Shrinkage Head-On: Testing for Real-World Durability

Shrinkage isn’t theoretical—it’s physical, often irreversible, and totally capable of ruining a well-made garment. So if a fabric is going to fail, better it fails in testing than in the hands of your customer.

That’s why Deepwear’s textile sourcing experts test under real-world stress to reduce shrinkage risks before production. Run them through heat, friction, moisture, and spin. Mimic the chaos of real-world laundry, not the ideal conditions on a care label because once your product is out in the world, it won’t always be dry-cleaned, gently pressed, or carefully handled. If a fabric can’t hold up to realistic wear and care, it’s the wrong choice for your design—no matter how good it looks on paper.

Shrinkage is manageable, but only if it’s confronted head-on. And the best time to do that? Before the first stitch is ever sewn.

Ready to reduce fabric shrinkage risks and protect product quality? Book a free strategy call with Deepwear’s textile sourcing experts or explore our shrinkage testing and sourcing solutions today.